DONATI SOLLEVAMENTI S.r.l. - Via Quasimodo,17 - 20025 Legnano (MI) - Tel. 0331 14811 - E: [email protected]

48

6.6 Replacing parts and components

To guarantee the operating safety of the “DGT”endcarriages units and endcarriages, it is

mandatory to use original spare parts or parts recommended by

DONATI SOLLEVAMENTI

S.r.l.

Operations regarding the replacement of parts and components must be performed by

qualified and specially trained personnel, and when working above ground level,

equipped with:

•

suitable individual protection devices (e.g. safety harnesses, etc.);

•

appropriate working tools (e.g. fork lift, crane, scaffolding, etc.).

after carefully evaluating the following parameters:

•

type of working environment, ambient specifications and type of flooring

•

height of the installation with respect to the flooring and available spaces

•

dimensions and weight of the parts to be replaced

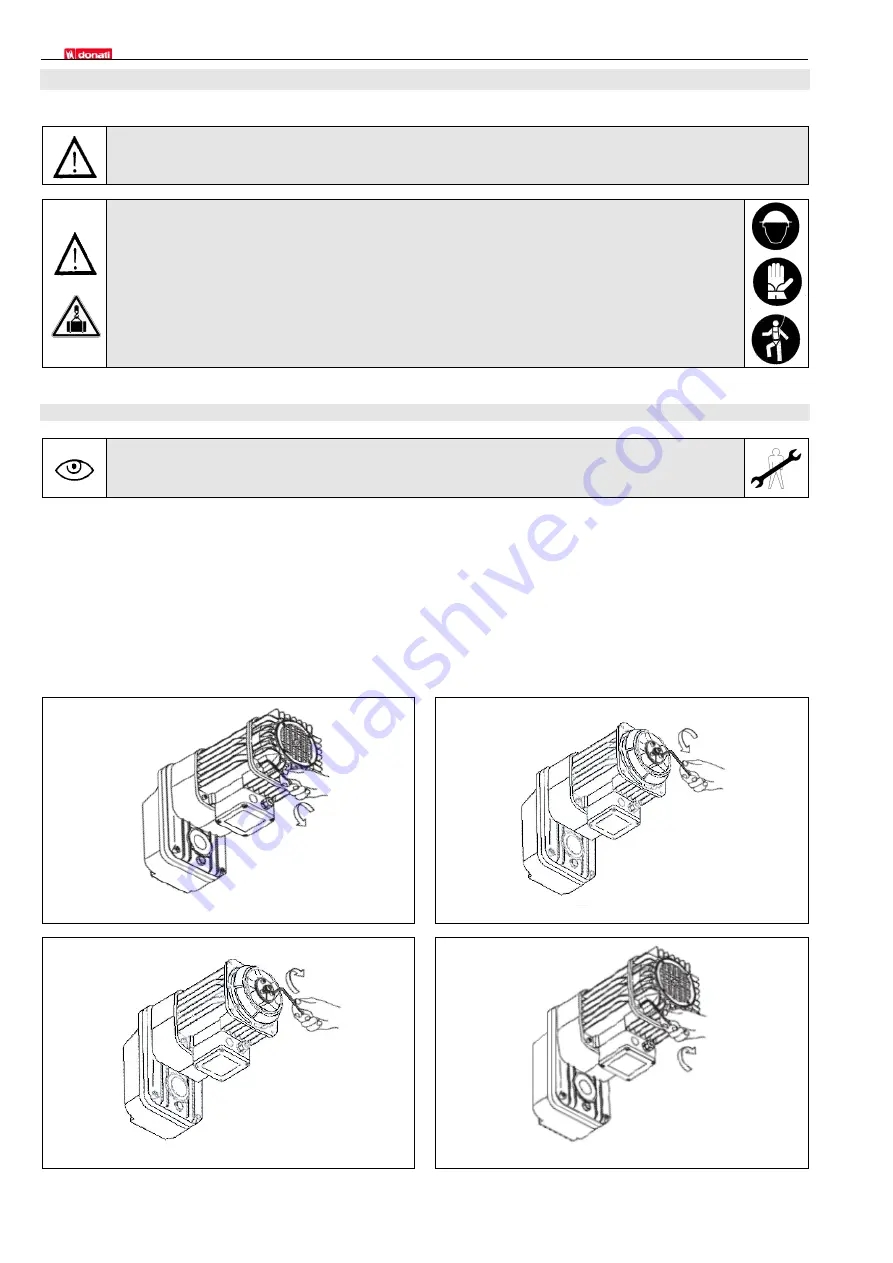

6.6.1 Replacing the brake on the motors on “DGT” drive units and endcarriages

To replace the motor brake proceed as follows:

1. Cut off power to the

“DGT” drive units

or

endcarriages

;

2. Access the work area safely;

3. Operating above ground level, remove the motor’s brake cover, unfastening the four screws (fig. 27);

4. Completely unscrew the three screws form the locking ring nut on the brake block (fig. 28);

5. Unfasten the ring nut and remove the brake block and its worn out material;

6. Reassemble the new brake block (with the new brake lining) and screw the ring nut back on to the end of its

stroke;

7. Fasten the ring nut to the brake block using the three screws (fig. 29);

8. Reassemble the motor cover, tightening it with the screws and nuts (fig. 30).

9. Proceed with the operating tests and adjustment of the braking torque as outlined at sect. 6.4.

fig. 27

fig. 28

fig. 29

fig. 30