DONATI SOLLEVAMENTI S.r.l. - Via Quasimodo,17 - 20025 Legnano (MI) - Tel. 0331 14811 - E: [email protected]

44

6.4 Setting the brake on the motors on “DGT” drive units and endcarriages

•

The motor on the “DGT” drive units and endcarriages is a self-braking type with axial shifting

of the rotor.

•

Braking is mechanic and is provided by a conical brake block, equipped with a brake lining

that is integral with the rotor, and which, in the absence of power, is thrust by a spring in

contact with the braking surface on the brake cover.

•

The brake linings do not contain asbestos, and are subject to wear depending on the intensity

of work operations.

•

Wear on the brake linings increases the amount of play between the lining and brake block;

this leads to a progressive loss of brake torque and consequent brake skidding and

lengthening of brake spaces; proper maintenance on the brake is consequently essential.

•

Adjust the brake torque as follows:

A) On the outside, adjust the brake torque in the case of modest wear or to modify preset

torque settings.

B) On the inside, restore the brake play in the case of heavy wear on the brake lining,

increasing the motor shaft axial stroke > 1 mm.

Adjustments on the brake on “DGT” drive units or endcarriages:

A) Externally set the brake torque

B) Internally restoring the brake play

WARNING! The use of a safety harness is mandatory when these operations

are conducted above ground level.

•

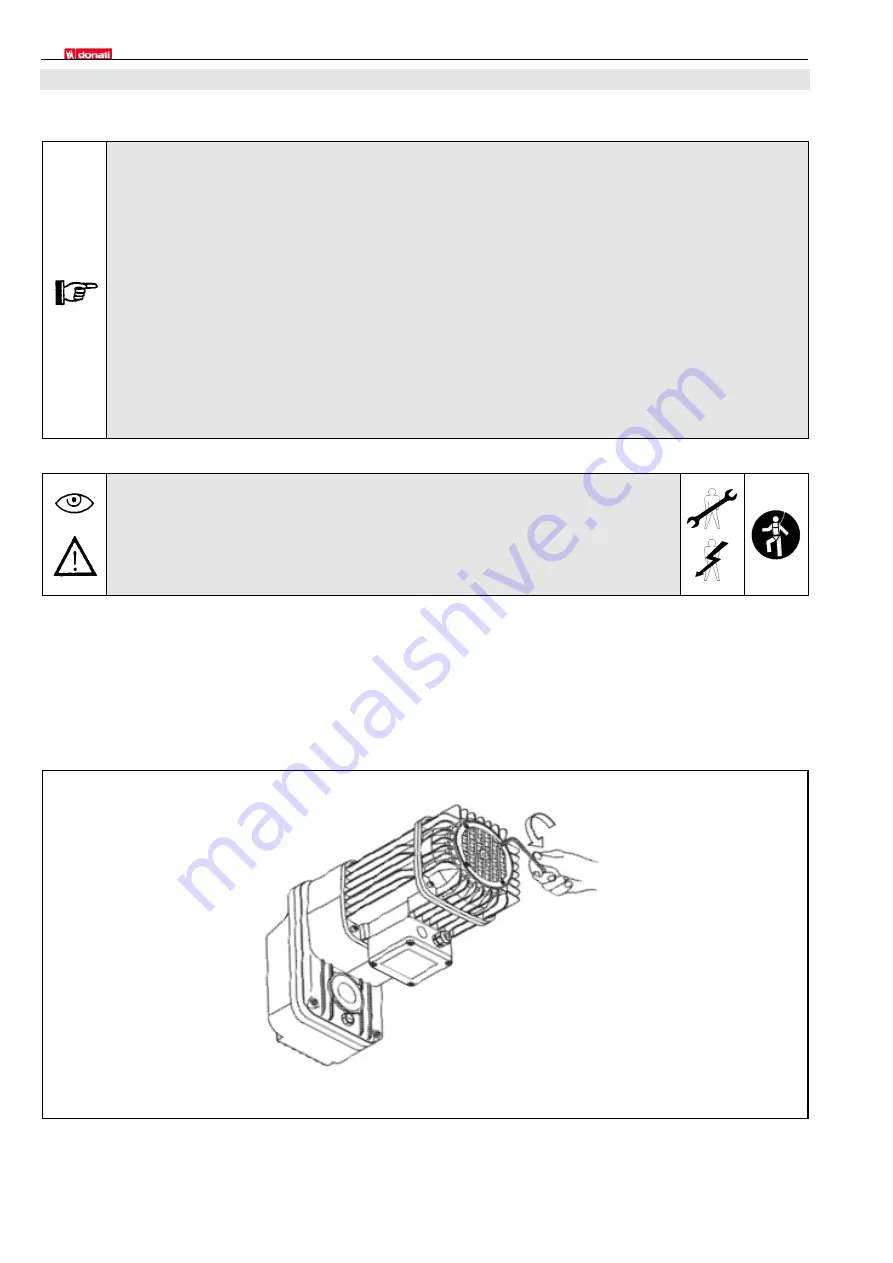

To make adjustments on the brake on

“DGT” drive units

or

endcarriages

, whether externally adjusting the

brake torque

A)

, or internally restoring the brake play

B)

, the following

PRELIMINARY OPERATIONS

are

required

:

1. Cut off power to the

“DGT” drive units

or

endcarriages

;

2. Get to the work area above ground level in safety;

3. Operating above ground level, remove the plastic grid (aerator), unscrewing the four screws completely, as

shown in fig. 16.

fig. 16