DONATI SOLLEVAMENTI S.r.l. - Via Quasimodo,17 - 20025 Legnano (MI) - Tel. 0331 14811 - E: [email protected]

47

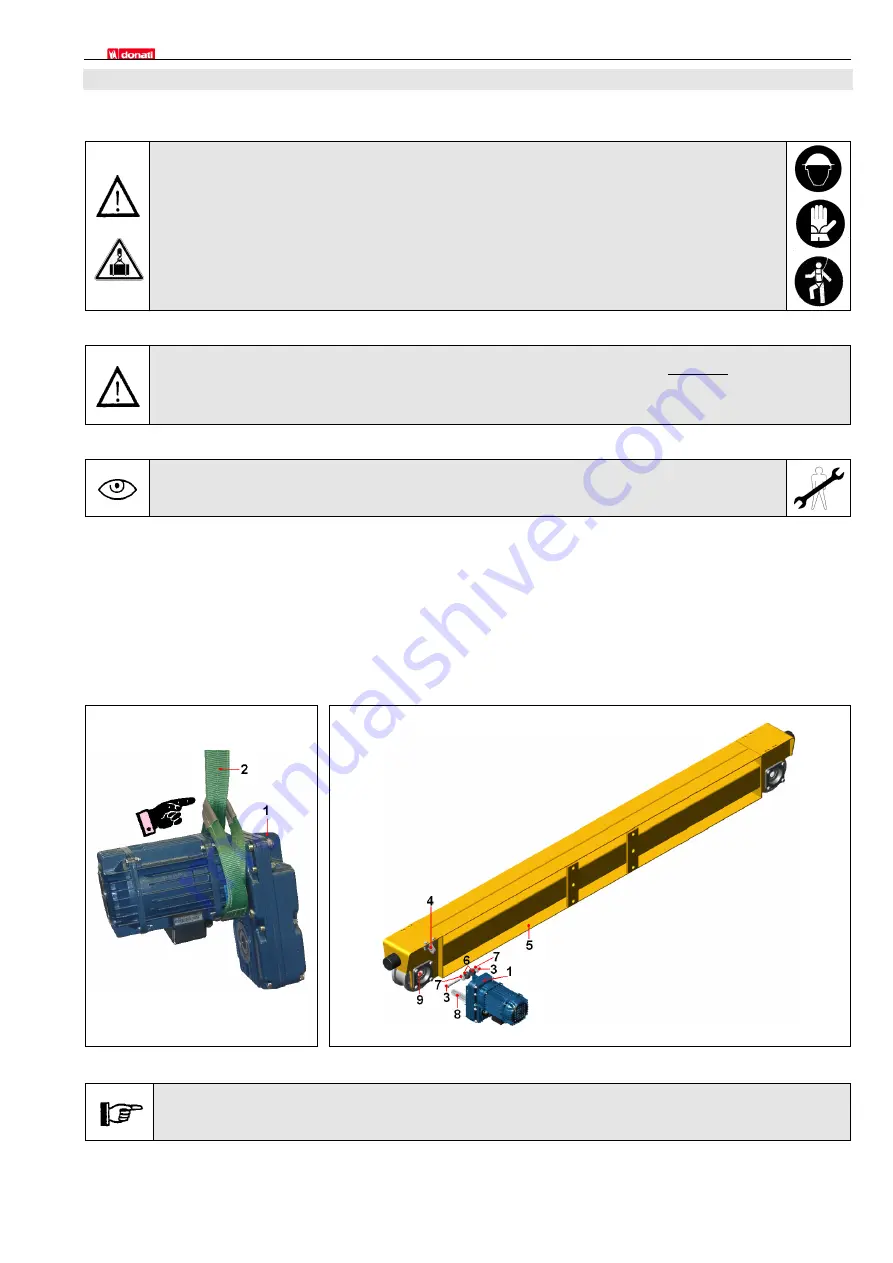

6.5 Disassembling the “DGP” offset gearmotor

Disassembly operations must be carried out by qualified and trained personnel, and

when working above ground level, equipped with:

•

suitable individual protection devices (e.g. safety harnesses, etc.);

•

appropriate working tools (e.g. fork lift, crane, scaffolding, etc.).

after carefully evaluating the following parameters:

•

type of working environment, ambient specifications and type of flooring

•

height of the installation with respect to the flooring and available spaces

•

dimensions and weight of the “DGP” offset gearmotor to disassemble

The “DGP” offset gearmotor being disassembled must be moved SOLELY using LIFTING

EQUIPMENT

(crane, hoist, etc.)

and

a suitable harness

(textile fabric sling)

fastened loop- like

onto the connection area between the motor and swinging reducer

(fig. 25)

.

Disassembling the “DGP” offset gearmotor

(fig. 26)

:

1. Cut off power to the

“DGT” drive units

or

endcarriages

;

2. Sling the offset gearmotor

(1), using a textile fabric sling

(2),

fastened loop-like onto the motor (fig. 25) without,

however, tensioning the harness;

3. Unfasten the screw and nut (3), and remove it from the reaction arm (4) on the operating head (5);

4. Remove from the gearmotor (1) the screw and nut (3) and shock absorber group, comprising two buffers (6) and

two pressure rings (7);

5. Completely extract the gearmotor (1), integral with the drive shaft (8), from the wheel (9), maintaining it

suspended from the lifting equipment with the harness (2);

6. Set the gearmotor (1) on the ground, operating the lifting equipment.

fig. 25

fig. 26

To reassemble the “DGP” offset gearmotor once more onto the operating head, proceed by

following the above steps in reverse sequence, i.e. as outlined in the procedure at page 50.