RF Baghouse, Models RFWP and RFWPH

4

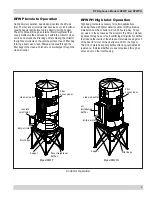

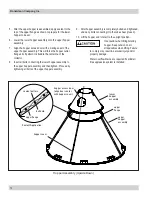

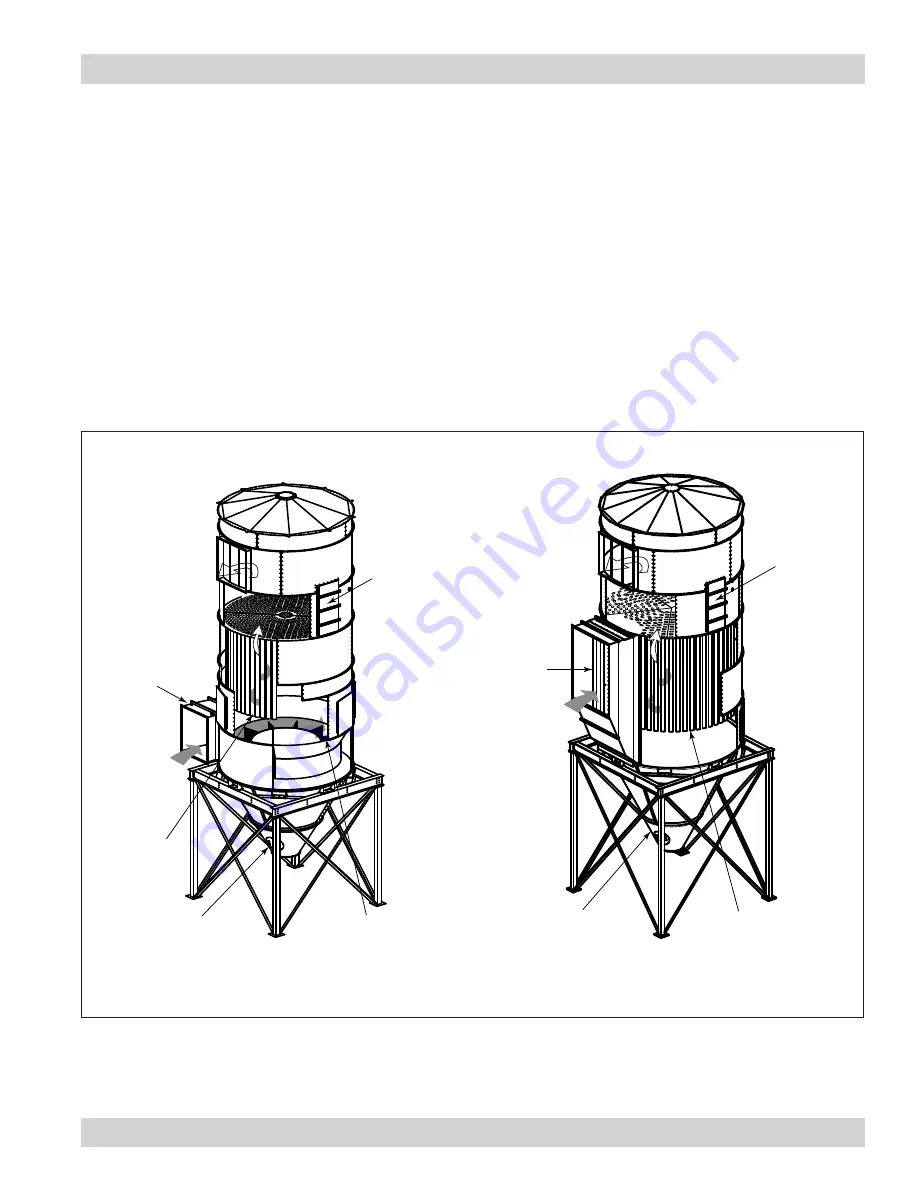

RFWP Involute Operation

During normal operation, dust-laden air enters the dirty-air

inlet. The involute scroll-style inlet develops a cyclonic airflow

causing heavier particulate to drop directly into the hopper.

The air continues through an internal flow straightener that

evenly distributes the dust-laden air within the collector cross-

section and around the filter bags. After entering the collector

the light dust collects on the outside surface of each filter bag

forming a dust cake. Clean, filtered air passes through the

filter bags to the clean-air plenum and discharges through the

clean-air outlet.

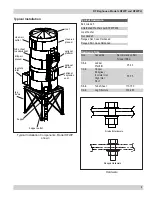

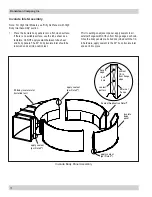

RFWPH High Inlet Operation

High body inlets are necessary for certain applications

including those with lighter density dusts or highly abrasive

materials when the collector will run 24 hours a day, 7 days

per week. In these cases as the air enters the dirty air plenum

it passes through a set of self-sacrificing air distribution baffles

that reduce the inertia of the abrasive materials causing much

of the dust to fall out of the air stream and into the hopper.

The 3/16-in plate heavy duty baffles offer long-term abrasion

resistance. Individual baffles are easily replaced through an

access door on the inlet housing.

filter

access door

flow straightener

baffles

filter bags

hopper

Model RFWP

Model RFWPH

dirty-air inlet

involute

scroll inlet

clean-air outlet

filter

access door

filter bags

hopper

dirty-air inlet

clean-air outlet

air

distribution

baffles

Collector Operation