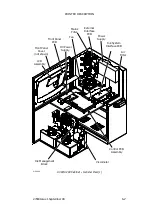

PRINTER DESCRIPTION

6--18

27080 Issue 1 September 98

Feed circuit.

Ink from the reservoir is supplied to the circuit by the high

pressure pump. The ink is pumped through a 5 micron filter, a jet pump

and then through a 69 mbar (1psi) Pressure Relief Valve (PRV) and back

into the reservoir. This circuit provides the different levels of pressure

to operate the other ink circuits. The electronics system checks the ink

temperature using a sensor encapsulated into part of the 1psi PRV.

The jet pump provides a restriction for the main pump to work against,

and as a result of the fluid flow through it, creates a vacuum in the bleed

line.

Pump pressure is measured by the pressure transducer mounted on the

ink management block which is read, and controlled, by the software.

Ink at pump pressure is fed through a solenoid valve and a 10 micron

filter into the drop generator in the print head. This ink is forced out

of the nozzle to form the ink jet. Nominal ink pressure at the printhead

is 2900mbar (42psi), or 4000mbar (60 psi) for Pinpoint.

An over--pressure PRV is incorporated and set to operate at 100psi in

case of over pressure in the feed circuit.

Gutter circuit.

Non--printed drops of ink from the ink jet are collected

in the gutter. This unused ink is drawn from the gutter through a filter

by the vacuum side of the pump and returned to the ink reservoir. The

gutter circuit operates continuously from start--up to shut--down. The

vacuum pump head is kept primed by a small supply of ink from the

pressure side of the pump.

Bleed circuit.

A second connection at the drop generator passes ink

through the bleed solenoid valve back to the reservoir via the jet pump.

Opening the bleed solenoid valve increases ink flow through the drop

generator and the inherent turbulence clears out any traces of air or

solid material. The bleed function is used automatically at start--up and

at shut--down. It can also be controlled manually for maintenance

purposes.

Viscosity control

. Periodic measurements of ink viscosity are taken

automatically. Ink at 69mbar (1psi) is taken from the junction between

the 1psi PRV and the jet pump, through a solenoid valve to the

viscometer. The output side of the viscometer is connected to pass ink

back to the reservoir. The viscometer itself consists of a ball in an

inclined tube. Ink flowing through the tube forces the ball to the top,

when the solenoid valve shuts off the ink flow, the ball falls back

Содержание A-SERIES

Страница 1: ...DOMINO A SERIES INK JET PRINTER OPERATION AND MAINTENANCE MANUAL ...

Страница 6: ... 6 27080 Issue 1 Sept 98 ...

Страница 8: ... 8 27080 Issue 1 Sept 98 ...

Страница 10: ... 10 27080 Issue 1 Sept 98 ...

Страница 12: ...HEALTH AND SAFETY 1 2 27080 Issue 1 August 98 ...

Страница 18: ...HEALTH AND SAFETY 1 8 27080 Issue 1 August 98 ...

Страница 20: ......

Страница 21: ......

Страница 22: ......

Страница 36: ...OPERATION 3 2 27080 Issue 1 August 98 ...

Страница 55: ...DISPLAY MESSAGES AND FAULT FINDING 4 2 27080 Issue 1 August 98 ...

Страница 76: ...REFERENCE 5 4 27080 Issue 1 August 98 ...

Страница 136: ...PRINTER DESCRIPTION 6 20 27080 Issue 1 September 98 ...

Страница 137: ...DESCRIPTION 27080 Issue 1 August 98 6 21 Wiring Diagram 37700W Iss 1 PELTI ER ...

Страница 138: ...DESCRIPTION 6 22 27080 Issue 1 August 98 ...

Страница 140: ...MAINTENANCE 7 2 27080 Issue 1 Sept 98 ...

Страница 142: ...MAINTENANCE 7 4 27080 Issue 1 Sept 98 ...

Страница 156: ...MAINTENANCE 7 18 27080 Issue 1 Sept 98 ...

Страница 158: ...REPAIR 8 2 27080 Issue 1 Sept 98 ...

Страница 192: ...REPAIR 8 36 27080 Issue 1 Sept 98 ...

Страница 198: ...SPARES AND ACCESSORIES 9 6 27080 Issue 1 Sept 98 5 6 7 8 2 3 1 4 9 Print Head General Detail CA002 1 4 4 ...

Страница 200: ...SPARES AND ACCESSORIES 9 8 27080 Issue 1 Sept 98 Ink System General 2 3 5 6 7 8 9 10 11 12 1 MG045_1 4 ...

Страница 202: ...SPARES AND ACCESSORIES 9 10 27080 Issue 1 Sept 98 Ink Management Block 1 2 3 4 5 6 7 8 9 10 6 MG046_1 ...

Страница 204: ...SPARES AND ACCESSORIES 9 12 27080 Issue 1 Sept 98 Electronics Door Assembly A300 A200 1 2 3 4 5 6 7 8 9 MG060_2 ...

Страница 206: ...SPARES AND ACCESSORIES 9 14 27080 Issue 1 Sept 98 Electronics Door Assembly A100 1 2 3 4 5 6 7 A1003_2 ...

Страница 208: ...SPARES AND ACCESSORIES 9 16 27080 Issue 1 Sept 98 Electronics Inner Door 1 2 3 4 5 6 7 ...

Страница 210: ...SPARES AND ACCESSORIES 9 18 27080 Issue 1 Sept 98 Electronics Cabinet MG067_2 1 2 3 4 5 6 7 8 10 11 12 13 14 15 9 ...

Страница 212: ...SPARES AND ACCESSORIES 9 20 27080 Issue 1 Sept 98 ...

Страница 214: ...OPTIONS 10 2 27080 Issue 1 Sept 98 ...

Страница 240: ...OPTIONS 10 28 27080 Issue 1 Sept 98 ...

Страница 242: ...APPENDIX A INSTALLATION A 2 27080 Issue 1 Sept 98 ...

Страница 261: ...APPENDIX B COMPRESSOR DRIVEN AIRDRYER B 2 20950 Issue 1 April 98 ...

Страница 300: ...APPENDIX B COMPRESSOR DRIVEN AIRDRYER 20950 Issue 1 April 98 B 41 37710W Issue 1 Airdryer Wiring Diagram ...

Страница 301: ...APPENDIX B COMPRESSOR DRIVEN AIRDRYER B 42 20950 Issue 1 April 98 AD032_1 Airdryer Power Diagram ...

Страница 302: ...APPENDIX B COMPRESSOR DRIVEN AIRDRYER 20950 Issue 1 April 98 B 43 This page is intentionally blank ...

Страница 310: ...20951 Issue 1 Apr 98 B 1 APPENDIX B AIR DRIVEN AIRDRYER AMENDMENT RECORD Amendment Date All pages at Issue 1 Apr 98 ...

Страница 311: ...APPENDIX B A SERIES AIR DRIVEN AIRDRYER B 2 20951 Issue 1 Apr 98 ...

Страница 313: ...APPENDIX B A SERIES AIR DRIVEN AIRDRYER B 4 20951 Issue 1 Apr 98 ...

Страница 330: ...APPENDIX B A SERIES AIR DRIVEN AIRDRYER 20951 Issue 1 Apr 98 B 21 37709W Issue 1 Airdryer Wiring Diagram ...

Страница 331: ...APPENDIX B A SERIES AIR DRIVEN AIRDRYER B 22 20951 Issue 1 Apr 98 Airdryer Power Diagram AD033_1 ...

Страница 332: ...APPENDIX B A SERIES AIR DRIVEN AIRDRYER 20951 Issue 1 Apr 98 B 23 This page is intentionally blank ...