PREVENTATIVE MAINTENANCE

It is recommended that the following maintenance be performed at 30 day intervals

on all HC1 34 tools which are in REGULAR DAILY SERVICE.

CLEANING AND LU BRICATING THE TOOL HEAD:

Inhi bitor with grit is a highly abrasive compound which must be cleaned from the

tool head at freq uent intervals. The procedure shown in LUBRICATING THE TOOL HEAD

should be followed to prevent excessive wear on the internal parts of the tool head.

CHEC K THE SYSTEM PRESSURE:

1. Check relief valve pressure setting using a DMC HPG-1 Pressure Gauge (see

ADJU STING PUMP SYSTEM PRESSU RE).

CHEC KING PUM P OIL LEVEL:

1. Check reservoir oil level of tool by rotating the advance handle clockwise. Oil

supply is adequate if the indenters touch before the Qdvance hQndle is c o mpletely

advanced. Ad d oil if req uired (see ADDITION OF HYDRAULIC OIL).

LOSS OF HYDRAU UC OIL:

Hydraulically actuated tools will gradually lose their hydraulic oil over a period of

time. This loss is caused by the a dherence of small amounts of oil to the moving

parts exposed to the outside, such as the plungers, pistons, and rams, and from

occasional leakag e around mechanical seals. A small loss of hydraulic oil is normal

and will not affect the operation of the HC134 tool. However, if the level drops too

low air can become trapped in the hydraulic system causing the tool to develop a

"spongy" feel, preventing it from operating . Occasional hydraulic oil checks can be

performed as follows.

P REVENTATIVE MAINTENANCE PROCEDURES

LU BRICATING TH E TOOL H EAO :

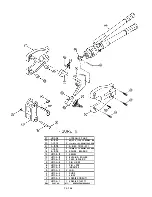

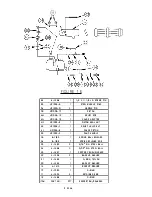

1. Disassem ble the tool head (see TOOL HEAD DISASSEMBLY steps 1 through 6) and

clean parts thoroughly by washing in an environmentally approved solvent. Wipe

parts clean and apply a coating of grease (see LUBRICATION RECOMMENDATIONS)

to the beari n g Qnd pin surfaces of Slide 4 {see Figure 5) and the beari n g surfaces

of each indenter (see Figu re 6).

2. Place bearing case 11 on the bearing surfaces of the indenter and apply a small

amount of grease in each roller cavity of the bearing case. Place bearing 1 6 in

each slot of case 1 1 a nd pack a small amount of grease after all the rolle r are

installed.

3. Follow steps 1 through 2 of

TOOL HEAD ASSEMBLY.

4. Wipe lubricant from indenter cri mping surfaces.

6 OF 2B

Содержание HC134

Страница 26: ...PORT ON SEE NOTE p SIDE E 1 6...