OPERATING INSTRU CTION S

CON DUCTOR PREPARATION :

1 . Usi n g a pro per insu lation stripping too l, strip the insu lation from the conductor, bei ng

ca reful not to nick the wire stra nds. Thoroug hly c le a n the conductor by wire brushing

-

a bright and shiny surfa ce is o btained. All oxides a nd foreign matter must be removed .

NOTE: Do n ot wire brush tin p lated coppe r conductors or tin n ed c o n nectors.

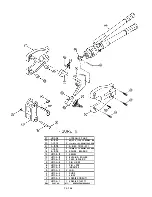

FIRST CRIMP AREA

-

--------

--------

0

CRIMPING AREA

C R I M P I N G AR EA

SPLICE

TERM I NAL

FIGURE 2

CRIM PI NG A SLEEVE CO NNECTO R:

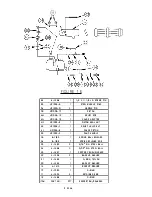

2. Pla ce a sleeve in the i n de nte r opening a nd rotate the adva nce ha ndle clockwise {see

(see Fig u re 1 ) until the indente rs l oose ly cla mp th e sleeve or terminal . Positi o n

th e sleeve or terminal so that t h e i nde nte rs will make t h e first crimp at t h e edg e

of the scored c rimp line marked on the barrel (see Figu re 2). Rotate each successive

cri m p 45· . NOTE: The n um ber of crimps wil l v a ry with each size sleeve or termina l .

3. Insert the cond uctor into the con nector socket ma king s u re that the cond uctor is

p ushed fu l ly against the center or end barrier.

4. Actuate the p u mp handle a nd the indenters wil l start com pressing the sleeve (see

Figu re 3). A positive trip acco m p a n ied by a distinct "click" will occur when the cri m p

is com pleted . Stop pu m ping . Back off the rapid adva nce ha nd le (rotate counter

clockwise) a p proxi m ately o n e - h a lf to one turn .

5. Release th e ind enters from the compressed s leeve by pa rtial ly raising the pu m p ha nd le.

Then rotate the h a n d le fu lly c lockwise and push inward {see Fig ure 1 ). The in de nters

wi ll o pen s ufficiently to a llow the s leeve to be repositioned for the next cri m ping

o peration.

CAUTION : DO NOT OPERATE TOOL WITHO UT PRO DUCT (LUG, SLEEVE, ETC.) IN PLACE.

SEVERE DAMAGE TO TH E TOO L WI LL RESULT.

4 OF 28

Содержание HC134

Страница 26: ...PORT ON SEE NOTE p SIDE E 1 6...