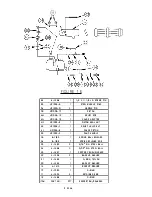

4. Tig hten jam screw 6 1 securely onto adjustment screw 8.

5. Reassemble the tool by reversing the order of operation described in

steps 1 through 4 in ADJ USTING PU MP SYSTEM PRESSURE.

6. To assemble remainder of pump, follow steps 1 th rough 9 in

REPLACING OIL PLUNGER.

"I

tim,p, �

1

I

I 1--n-----<f)-

1 1

"""1n

PRESSURE

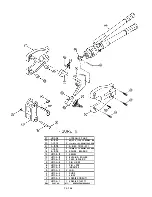

FIGURE 1 0

ADJUSTMENT OF PUMP SYSTEM PRESSURE:

1 . Adjusting the system pressure requires a DMC HPG1 Pressure Gauge.

2. Screw the HPG- 1 Gauge onto the gauge adapter 45 located on the bottom

side of the pump (see Figure 1 0) .

CAUTION: HAND TIGHTEN GAUGE TO THE PUM P ADAPTO R ONLY! DO NOT OVERTIG HTEN!

3. Place a connector in the indenter area and perform a crimp. Observe the needle

position when th e pump clicks and release is hea rd. The needle should be in

the ·GREEN" area of the ga uge.

4. If adjustment is needed, follow steps 1 through 7 of ADDITION OF HYDRAU LIC

_QlL

5. Hold the pump in a vertical position with the oil reservoir u p, remove loc king

screw 6 1 and tighten adjusting screw 8 to raise the pressure or loosen screw 8

to lower the press ure.

6. Replace locking screw 6 1 and follow steps 8 through 10 of ADDITON OF

HYDRAU LIC OIL.

12 OF 2S

Содержание HC134

Страница 26: ...PORT ON SEE NOTE p SIDE E 1 6...