�

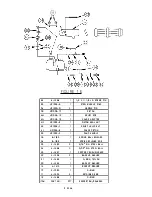

8-1 1811

:I.

!PRING, OUT

32

8-1 187

1

SPRING, INLE:T

�I

15-111115

1

SPRNO, HANlLE AETIJRN

30

15-1 1B!!

1

SPRINO, PUJNIER

29

11-1 184

1

SPRIN� R ... 11 RElURN

2B

2.7

B-1 145

I

1 /4" X 1" L..ON!l DOWEL PIN

:ZS

+-1411(]

2

J/111" DIA. Sim IIALl.

a-lROME R e 58- 65

25

+-1"159

2

t/J:t' DIA. S1EEI.. BALL

a-lROME R c 58- 65

J4

4-1458

3

5/J2" DIA. S1EEI.. BALL

a-lROME R c 58- 65

.2ll

4-1�7

1

00PPER CRUSH WASHER

• 750 X . 379 X . 040

4

.22

4-141!11

1

!WlK-U' WASMER

MS28774-01 1

;!I

2.1

4-14!!!1

1

D-NO, 1EFL<»I

S1 1 7J2-01 1

3

Z0

+-14�

1

BACK-UP WA!i!ER

8-006-N 300-9 0

7

1 D

+-1463

I

OOPPER CRUSH w.\SHER

.31 1 X .191 X .D40 4

111

+-1462

1

VAAISEAI...

S.32240-21 B-Y1 106S 5

17

+-1+45

2

RETAINNG RIN!l

5D05-J7

e;

1 &

+-14-22

1

0-RING

2.-222 N70

8

15

4-1 41 1!

:I.

HANDLE GRIP

21 DJ-.34:1024

2

14

4--1 41 !1

1

BM:K-U' WASMER

8-004-NJ00-90

.7

--->.

I�

4-1487

1

tl�Nll

2.-01 1 N 70

8

m

12.

4--1JM

1

D-NO

2- 004 N70

1 8

11

+-10:Z4

4

RETAINNCl RING

51 33-25

1 6

10

+-14811

I

!!�NC

2- 006 N70

8

t

1-1 111-4

1

10-�2 X 1" CIJP Pr, SOC:. SET SCA.

B

1-1 �

1 15/8-:1.4 X 3/B SET SCR,(MOlllFY.

7

1-1853

1

Fill.ER SCREW

I

1-1282

:I. 1/ 4'-:ZO X 1/2 BUT.HD.SX:.C:AP l5CR.

I!

1-1 211!1

1

1 D-J2 X 1 /4 FLT. PT. SE:T SCR.

4

1-1 :ZSD

1

1 D-� X 1 -1/4 !!CIC. HD. CAP !CR.

;,

1-1 :z<J1

1

&-:52 X !1/a DOC PT. SET SIR.

:z

1 -1 1 lil0

2.

B-.l2 X 1 /II CUP Pl". SET SiCR.

1

1 -1(1111

I

1/+-211 X ,z, FLT, PT. 5ET,9a'I,

llEM

PART NO.

QTY,

DE9CAIPTI0N/AEMAR1CS

MFG."5 PART NMBER

112

B-1 2=18

1

1 /4 X 1-1 /a LONG SPRING PIN

111

1 -1115"7

I

.3/11-24 X !I/II ADJ. S�

11(1

4-1 48:1:

2

BUMPER STOP

59

HP1036..S

1

Bt.a<-UP RNG

511

4-1 46&

.1>21>

HYDRAULIC OIL

57

I-PI QJB-24

1

MOVABLE: HANDLE

1!11

tf'l �15-:Z!I

1

FIXED I-WIDLE

1!11

IF1 D;:115-22

2

SPRING AETAN.lt

!14-

HP1 DJ&-21

2

HANDLE PIN

�

52

HP1038-111

I

HEAD ... DAP10R

fll

HP1011B-18

1

RAN

5(1

HP1011B-17

1

PISTON

�

MP1031!-15

1

PSI Vt.LIIE

411

MP1031!-1J

1

REL.Ef ROD

47

HPlll!ll!l-1:Z

1

PLUNGER

4a

HP1G!lli-11

1

RELEASE: MANDU:

....,

HP11J;'ll;-11J

1

OAUIE, ADAPTOR

44-

HP11J:!lll-8

1

ADVANCE HANDLE

4J

HP1036--8

I

Pl5nJN SEAL NUT

4.:1

HP1036-7

1

RELIEF VALVE NUT

41

HP10118-B

1

GAUGE: PISTON

4(1

MP1 0J&-4

1

COVER

:59

MP10:lll--3

1

Pl.MP Mt.NDLE

!Ill

HP111:115-2.

1

MANDLE S'1EM

'S1

HP10:!1!5--1

1

PUMP Btll>Y

;,&

8-11 "1

1

SPRING PSI

35

8-11 DO

I

SPRINO BAU REL£A!1£

1l4-

8-11 B8

I

SPRIN!l RELEASE ROI>

llt:N

PART NO,

QTY,

DESCRIPTION/RE:MARKS

BUMPER STOP

(2}

PARACDE H "ID.. O L AW..,.

{ 1 }

I.Fe. "s PART NUNBER

INDE:X

or

MANUFACTURERS

1. DRYDEN OI L COM PANY

BAL Tl MQRE, MD

2. A lLANllC INDIA RU BBE R CO.

GOSHEN INDI ANA

3.

W.S, SH AMBAN & CO.

FT. WAYN E, IN

4. BOKER'S INC.

MI N N EAPOLI S, MN

5. AMER ICAN VARISEAL

BROOMFIELD, CO

IL WALDES K OHI NOOR, I N C.

y

LON G I SLAND CI TY, N

7. CHI CAGO- ALLI S MFG. COR P.

a-ii CAGO, IL

8, PARKER SEAL GROUP

LEXI N GTON, KY

Содержание HC134

Страница 26: ...PORT ON SEE NOTE p SIDE E 1 6...