1:illIE.: Cover the open end of the oil cylinder with a cloth or paper towel!

Slowly apply pressure to the relief rod (see Figure 1 ) to bleed any air out

of the system. This procedure may have to be repeated several

times to remove <lll of the air that may be trapped in the system.

7. Once assured the system is free of air, fill the reservoir with the proper

hydraulic oil (see COLD WEATHER NOTE).

8. Apply slight pressure to plunger 47 (see Figure 8) to allow the oil to

just reach the su rface of the fill hole, then replace the filler screw 7 and

0-ring 1 3.

9 . Reassemble the tool by reversing the order of operations described in

steps 3 through 5 in ADDITION OF HYDRAULIC OIL.

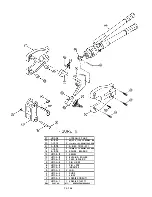

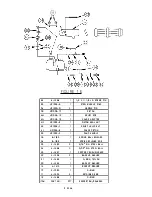

FIGURE 9

INSPECTION/R EPLACEMENT

or

PR ESSU RE ADJ USTI NG VALVE:

1 . Follow recommended steps of ADDITION OF HYDRAULIC OIL.

2. With the pump securely held in a soft jaw vise, remove the locking s crew

6 1 and adju sting screw 8 (see Figure 9) .

3. Invert the pum p over a work tray or absorbent paper towel. With the

open end facing the tray or towel, sha ke the tool slightly to remove spring 36

and PSI valve 49.

4. Inspect PSI valve 49 surface for wear on the conical shaped area of the

valve.

CAUTION : IF DAMAGE IS OBSERVED, DO NOT ATIEMPT TO REPAIR THIS VALVE.

A NEW VALVE S HOU LD BE INSTALLEDJ

INSTALLION OF PSI VALVE:

1. Install PS I valve 49 in the pump c<lvity and place the PS I spring 36 in the

bore of the PSI valve (see Figure 9) .

2. Tighten adjusting screw B so it is fully bottomed out.

3. After tightening adjusting screw 8, loosen it 3/ 4 to 1 turn for a preliminary

adjustment position.

1 1 OF 2B

Содержание HC134

Страница 26: ...PORT ON SEE NOTE p SIDE E 1 6...