27

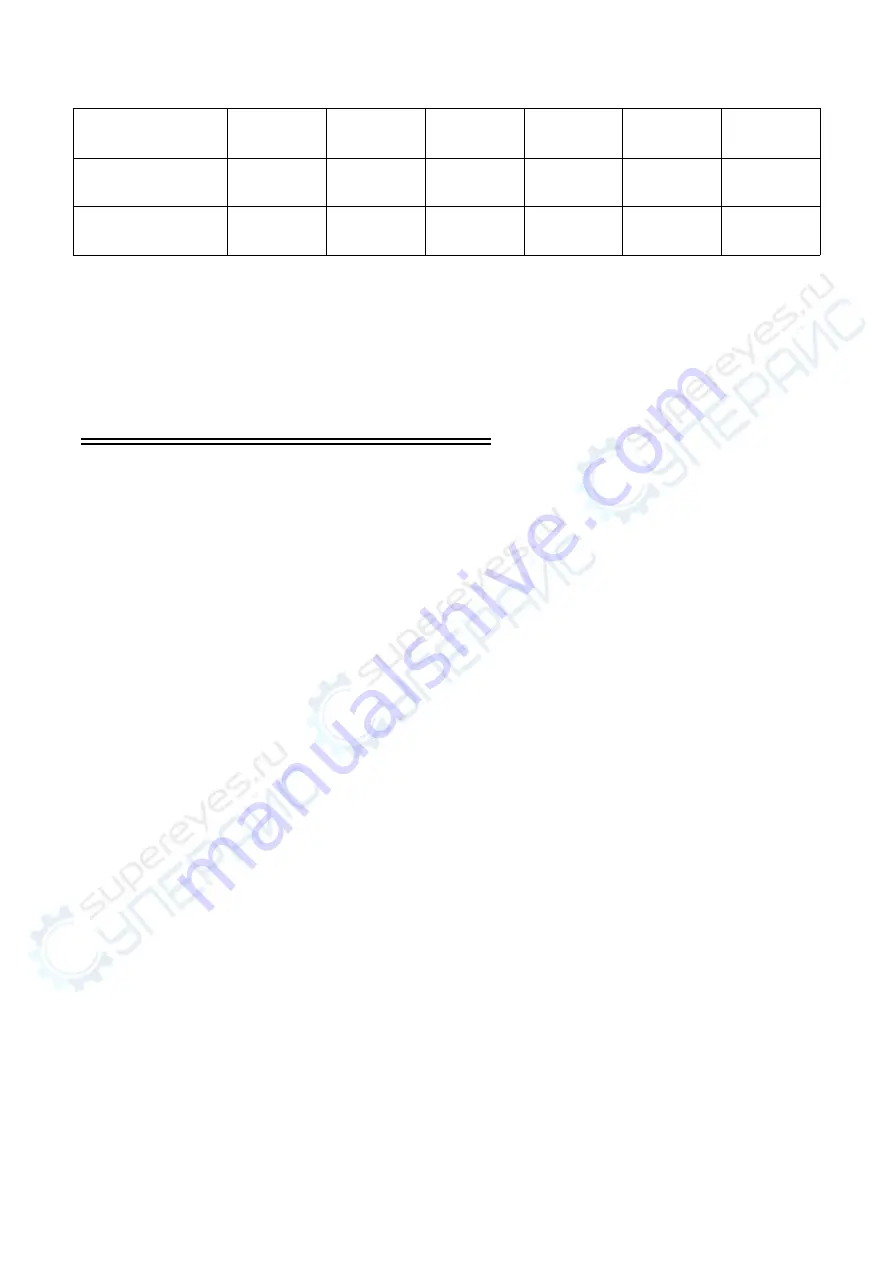

Infrared

temperature

180

0

0

0

0

0

Constant time

300

0

0

0

0

0

Infrared

rate

3

0

0

0

0

0

Above reference temperature are for the lead-free products

Above are Intel lead-free BGA temperature references

If you want to dismounting the BGA chip, the cooling temperature can be set 0

I Announcements of BGA operation

1.After opening the power, firstly you should check whether the upper and

bottom hot air nozzles have cold wind If not, starting the power is strictly

prohibited, or the heaters will be burnt The bottom infrared heating areas are all

controlled by switch, and you can choose the bottom heating areas depend on the

PCB board size

2. You should set different temperature curves when repair different BGA,

each temperature should not higher than 300

℃

Lead-free rework setting

can refer to welding temperature curve of BGA tin bead

3. When demount BGA, the cooling fan and vacuum should be set to

automatic transmission,

The buzzer will warn automatically when temperature curve runs to the

end Meanwhile, dismounting the BGA from PCB board with vacuum

pen, and then dismounting the PCB board from the positioning frame

4. When welding the BGA chip, set the cooling fan to manual grade. close

vacuum After the temperature curve runs to the end, the buzzer will

alarm automatically, the cooling fan begins to cooling the BGA chip

and bottom heating zone, meanwhile, the warm heating head will blow

a cold wind Then elevate the upper heater, make the gap has 3-5mm

space between the bottom of nozzle and the upper surface of BGA chip

and keep cooling for 30-40 seconds, or move away the main heater after

the starting light is off, finally take away the PCB board from the

support

5.Before installation of BGA, it is necessary to check that if the PCB pad

and BGA tin bead are all in good condition It is necessary to check the

outlet after welding and to stop installation if you find something

unusual Go on welding after anything is normal, or the BGA and PCB