18

This machine could apply to in soldering and desoldering the BGA chip

1. Preheating:

Preheating before reworking, the temperature of constant temperature oven is set

at 80

℃

-100

℃

, for 4-8 hours to demoist the PCBA ,to prevent the explose during

reworking

2. Desoldering

1

)

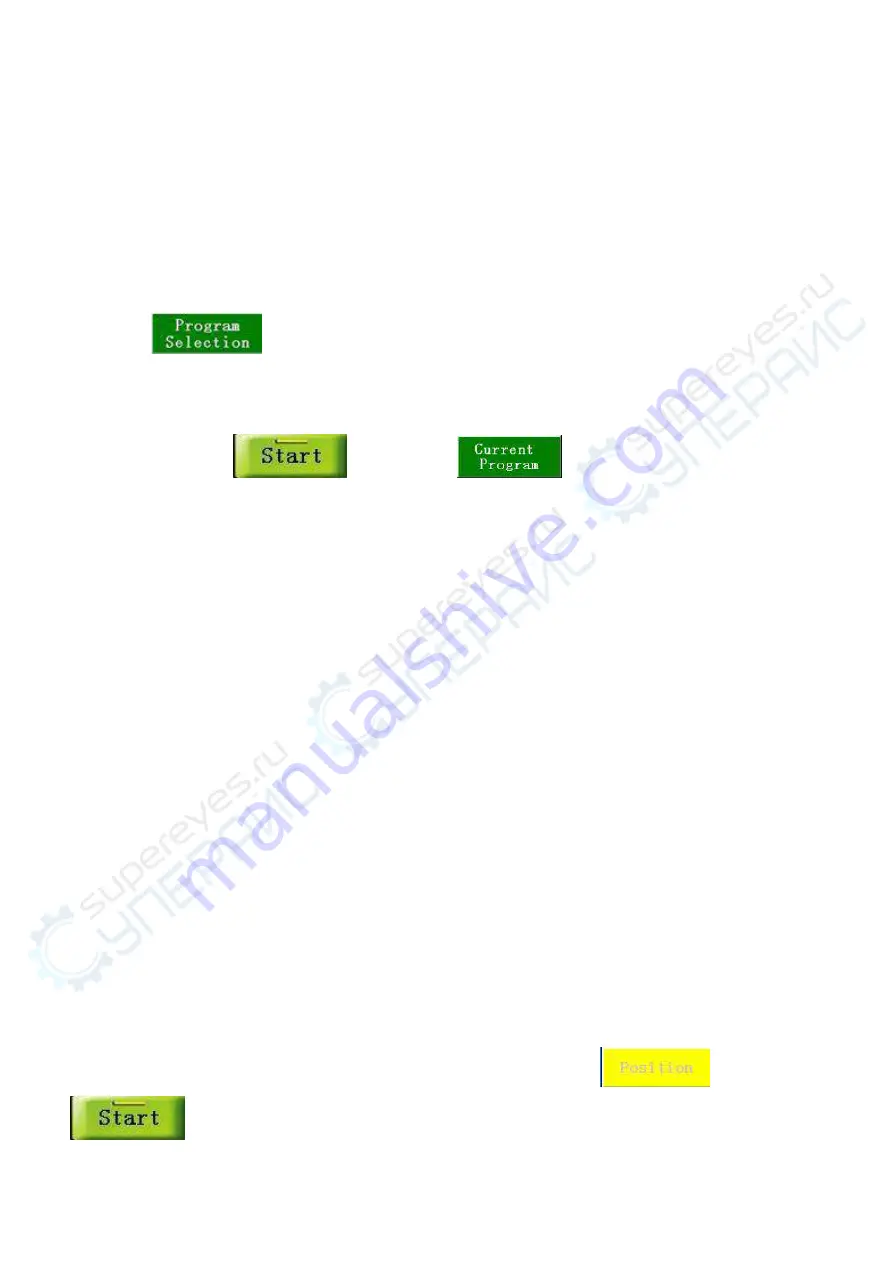

.Swith the power on , the touch screen will enter the main working interface (picture

5)click

to select the proper profile (If the profile are not suitable, you

can set the profile as mentioned above )

2).Keep the center of upper and bottom heaters in a vertical line when positioning,

then fix the PCB clip Keep the bottom of the nozzle of upper heater 2-3mm above

BGA chip Click

to run the

, then it will work as you set

After the process finished, raise up the Upper heater, then take the BGA chip off with

vacuum pen,the procedure of desoldering is finished

3.Clean-up the pad

You can clean-up the BGA pad with wick line; the best way to dismounting the tin

right after the BGA removed and the temperature difference make less damage to the

pad; It can improve the activity of soldering tin with the flux and is better to clean the

soldering tin Pay attention that do not to damage the PCB pad, and in order to ensure

the reliability of BGA solder, try to use some volatile solvents when cleaning the pad,

such as plate washer water, industrial alcohol

4.BGA re-balling

Apply the paste flux evenly with the brush pen on the BGA pad, fix it on the BGA reball

fixture, choose the right stencil, and then plant tin balls properly

5.Soldering BGA balls

After setting the BGA reball station properly, put the reballed BGA chip on it, remove it

after the ball is soldered

6

.

Apply paste flux

Apply the paste flux with the brush pen on the PCB pad If you apply so much, it will

cause connected welding, on the contrary, it will cause null welding In order to wipe

off dust and impurity of tin balls, and enhance welding effect, the welding paste must

be wiped equally

7. Alignment

1).

Turn on the laser, make sure the laser is pointed to the center of the pad for the BGA,

put the BGA chip on the PCB board

2).

Select the proper temperature profile, choose the model

, then click