�

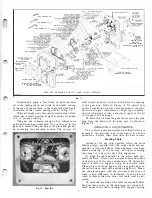

EX WRENCH SP-I

�

EX WRENCH

SP-5

�

WRENCH SP-IO

PLR-5 GEAR BOX

PLR·es GASKET

COVER PLATE

PLR-22

MACH. SCREW

'5

(4) PLR-1 3

SP-2436 PIPE PLUG

(4) SP-112 CAP SCRE

.c

(2)

SP-140 CAP SCREW

SP-206 SET SCREW

PLR-315

SWITCH COVER PLR-90

MACHINE SCREW

(2) SP-504

WASHER

(2)

SP-1603

FINISHED SIZE

p

C��f

_SASSEM.

GEAR BOX MECHANISM AND LEFT-HAND COLUMN ASSEMBLY

5-23-51

Fig.

1 1.

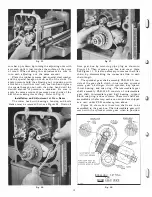

Occasionally apply a few drops of light machine

oil to the table gibs on each side of the table casting

at the rear of the machine so the table will slide freely

in relation to the column castings. Refer to Fig. 1 5.

Wipe all bright parts frequently with a clean cloth

which has a small portion of light machine oil added

to it to prevent rusting.

The gear box contains enough oil to lubricate its

gears and bearings constantly. To put this oil in the

gear box, remove the gear box cover plate and gasket,

by removing four machine screws. The correct oil

Fig.

12. Gear Box.

7

level should be about Y4 of an inch below the opening

in the gear box. Refer to Figure 1 2. To permit this

positive lubrication we have incorporated in conjunc

tion with the gear mechanism a slinger type construc

tion which always carries a constant supply of the oil

to the gears and bearings.

To drain this oil from the gear case remove the pipe

plug from the bottom of the gear case, as shown in

Figure 20.

OPERATING ADJUSTMENTS

The controls and adjustments described below are

important for accuracy and convenience in various

operations. Follow these directions for best results.

Leveling Table

Accurate cuts are only possible when the knife

blades project equally from the cutter head and are

parallel to the work table. This alignment has been

made accurately at the factory, but upon receiving

the planer it is best to check this alignment.

To align the table parallel to the cutter head pro

ceed as follows : Dress down two pieces of wood square

until they are of the same dimensions. To obtain ac

curate results, we suggest using an accurate scale.

Place a piece of wood against the steel guide bars on

the table, one on each side, and take a light cut. Meas

ure the pieces again with the accurate scale to see if

there is any difference in thickness. If one piece of

wood is thicker than the other, the table must be ad

justed.

To raise the low side of the table loosen the fillister

head machine screw in the adjusting nut support lo

cated beneath the table casting. We suggest raising

Содержание Milwaukee PM-1738

Страница 1: ...13x5 INCH DELTA MILWAUKEE 7 7 1M rJ6fiUAKJ PM 1738 ...

Страница 2: ......

Страница 27: ......

Страница 28: ......