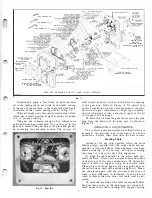

TAB

ROLL

(IDLER)

HEX. HD. SET SCR.

BAR

KNIFE BLADE

RIGHT

HAND

COLUMN

1 0 - 23-50

CROSS

SECTIONAL VIEW

OF PLANER HEAD

F i g . 40.

PLANER OPERATIONS

The following instructions will give the inexpe

rienced operator a start on the usual planer operations.

Use scrap material for practice, checking the settings

before attempting the job at hand.

First the stock is placed on the table and moved

forward until it is pushed into the machine by the

serrated in-feed roll which is held down by means of

compression springs at each end of it. After the stock

passes beyond this roll a short distance it comes in

contact with the chip breaker. The chip breaker pivots

on the front tie bar and automatically raises with the

serrated in-feed roll.

The shavings removed from the stock are carried

up and thrown out at the rear of the machine. As the

stock leaves the revolving knife blades in the cutter

head it passes beneath a pressure bar, the purpose of

which is to hold down the stock flat on the table firmly

as the knife blades are performing the job. The pres

sure bar also insures a perfectly smooth planed surface

since it helps to prevent chattering, waves in the mate

rial and any irregular planing of the stock. It must be

set even with the cutting circle, and it is easily ad

justed to it. Its pressure can be readily varied as

desired.

The stock next passes beneath the smooth out-feed

roll which pulls the stock out of the machine at the

same rate of feed as the in-feed roll pushes the stock

into the machine. This roll is also held down by means

of compression springs to give it the required pressure

for the stock being planed. Refer to Fig. 40.

17

It can be noticed that the table of the planer has

two cylindrical rollers (idlers) which can be adjusted

for the type of lumber that passes over the table. For

smooth lumber these rolls are best set at .005" above

the table surface and for rough lumber these rollers can

be set above the table surface the desired amount up to

.010" .. Caution : If the table rollers (idlers) are adjusted

too hlgh (more than .010") the knife blades in the cut

ter head may chip or splinter the edge on the end of the

stock. The object of these (idler) rollers is to eliminate

the lumber from dragging on the table surface. The

table rollers are spaced apart 5Yz" on centers.

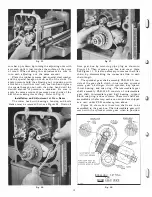

Short pieces of stock less than 6" long must be

fed through the machine by a "following block" which

has the same thickness as the piece being fed.

Preparing Stock For Planing

The planer is a machine which will reduce stock

to the thickness required. It will not reduce or elimi

nate "warping" of the stock as we sometimes think.

To remove warping from the stock it must be jointed.

The planer will then perform the operation of reducing

the stock to the desired thickness.

After a little practice, usually the operator can

sense by the sound of the machine whether the cut

being taken is too heavy. Always decrease the cut by

lowering the table slightly. Usually a 1/16" cut is

sufficient for most operations.

We suggest taking successive light cuts until the

desired thickness is obtained. Where several pieces

are to be planed, the thickest piece is planed first, then

the others are planed in order of their thickness.

Содержание Milwaukee PM-1738

Страница 1: ...13x5 INCH DELTA MILWAUKEE 7 7 1M rJ6fiUAKJ PM 1738 ...

Страница 2: ......

Страница 27: ......

Страница 28: ......