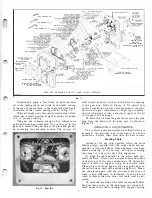

Fig.

4 1.

View Showing Cutter Head and Feed Mechanism.

Reducing Stock ond Direction of Grain

Often the stock can be reduced to the desired thick

ness by a single cut. We suggest using scrap stock

to test the accuracy of the setting by measuring it

with an accurate scale.

It is good practice to remove an equal amount of

material from each face of the stock by taking alternate

cuts. The object of taking a cut first on one face of

the stock then from the other face is to remove an

equal amount of stock from each side of the piece. This

will help equalize shrinkage which otherwise would

be unequal because of the difference in the moisture

content of the two surfaces.

Always feed the work into the planer with the

grain. Feeding the stock against the grain may result

in chipped and splintered edges.

For best results, we suggest taking light cuts of

1 /32" only. If successive light cuts are necessary turn

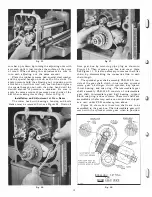

Fig.

42.

Front View- Planing Heavy Stock.

18

Fig.

43.

Rear View - Planing Heavy Stock.

the thin stock over and plane alternate surfaces until

the desired thickness is obtained.

Planing Thin Stock

Planing thin stock on the Delta planer enables the

operator to produce a nice smooth even surface on

the material as thin as 1

/

16". Refer to Figs. 44 and 45.

Sometimes pieces thinner than 1 / 1 6" is necessary

and this too is easily accomplished on the Delta planer.

For instance, when it is necessary to reduce the thick

ness of the stock thinner than 1 / 16", we suggest the

operator use a "backing board."

When reducing the stock less than 1 / 1 6" proceed

as follows: Reduce the stock to be planed to about

3/1 6". We suggest the operator select a straight board

approximately 1" thick which is slightly wider and

longer than the thin stock. Plane the 1 " stock to reduce

it to a uniform thickness, but not less than %" to

Fig.

44.

Front View- Planing Thin Stock.

Содержание Milwaukee PM-1738

Страница 1: ...13x5 INCH DELTA MILWAUKEE 7 7 1M rJ6fiUAKJ PM 1738 ...

Страница 2: ......

Страница 27: ......

Страница 28: ......