4.

Anchor holes can be marked and drilled with bases in place.

Consult Appendix C for anchor hole pattern. All anchor

holes in base are required to be used to meet seismic re-

quirements. Consult local building codes for anchor

bolt requirements. Anchor bolts not included due to site

specific requirements.

5.

Remove hardware holding modules together and holding

modules to skid. Hardware removed from modules will

be reused to attach modules to bases and to each other.

Hardware holding modules to skid can be discarded.

6. Module / Base Shimming

a. Prior to installation, the floor on which the battery

string is to be installed should be level and capable of

supporting the weight of the battery string. A 1° taper

on a floor can result in a ½" variation at the top of one

eight-high stack of modules. This can be compounded

by the tolerance of each module.

b. Standard steel shim stock such as AISI/SAE 1010 can be

used. Stainless steel is not required since these batteries

are AGM and should not be exposed to a corrosive

environment. Shim dimensions will vary depending on

the location and levelness. Shims are not provided by

East Penn due to site specific requirements.

c. If floors are not level, shim material can be placed under

each of the base supports within a battery string until

they are level. All base supports within a battery string

must be level with each other – do not level individual

bases as this could cause variation in height from one

stack to another.

d. It is recommend to place an interstack connector on the

system to ensure no stress will be placed on the cell

posts. Reference Safety Section of this manual and

battery schematic for all necessary precautions. If the

connector is aligned, it may be removed and the module

installation can continue.

e. Reference Appendix C for

Base Support layout dimensions

f. Once all the modules are installed and aligned, joining

plates (pg b.7 Part 3) which are provided with the parts

kit should be installed at the top of every stack. This

provides an additional tool to ensure levelness.

g. Assuming these guidelines are followed, the electrical

connections can be installed easily without any issues

of misalignment or undue stress on the cell posts.

CAUTION: Never lift more than one module at a time with

the supplied lifting slings.

7. Install modules onto bases using supplied lifting straps.

Two straps required to lift each module. Consult below

diagram for proper sling attachment.

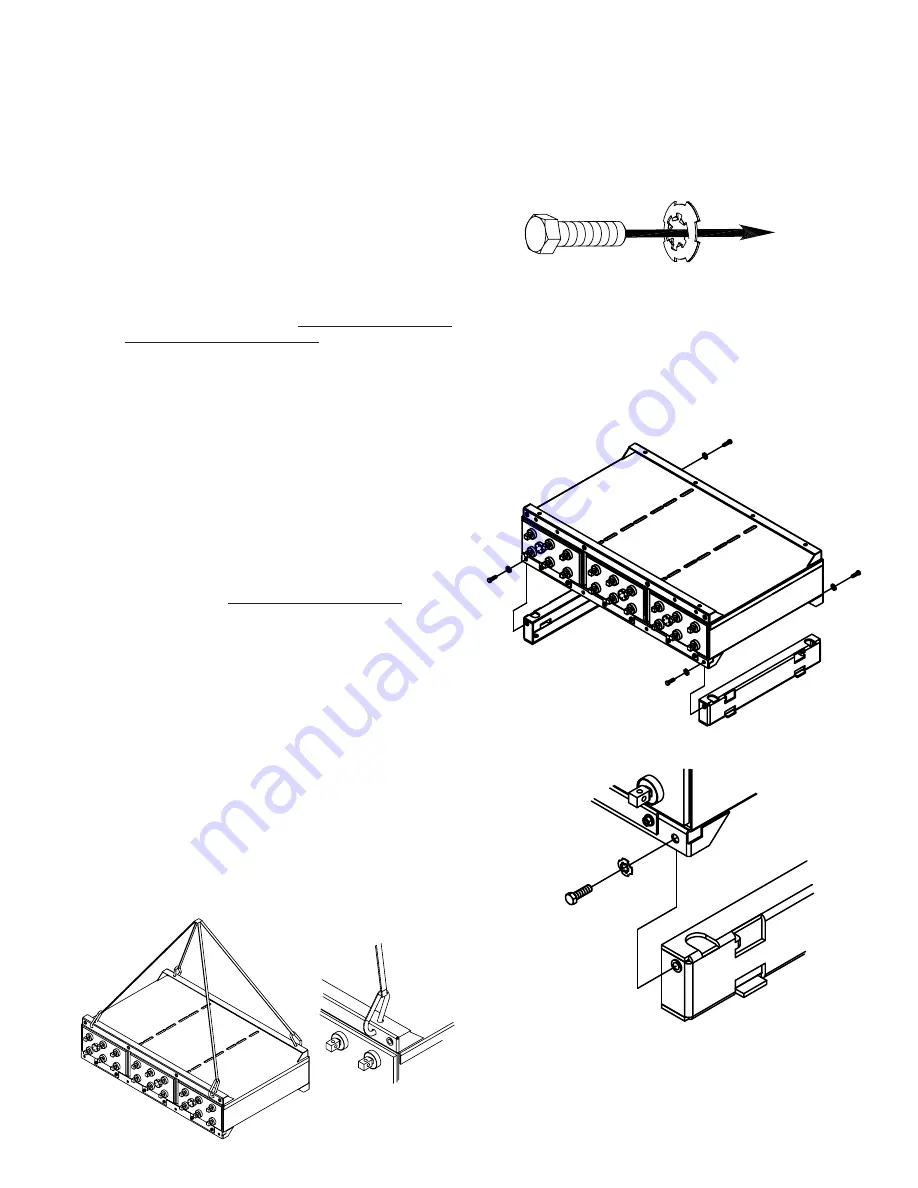

8. Module connecting hardware is furnished with a dragon tooth

washer in place of a lock washer and flat washer.

The dragon tooth washer is used to enhance the electrical

conductivity of the grounding system within a stack of

modules. To ensure the dragon tooth washer is installed

correctly; the curve of the washer must face away from the

bolt head. Stack to stack grounding electrical conductivity

is the responsibility of the installer.

b.5

9. Installed battery string should be compared to battery string

layout drawing for correctness. As each module is installed

all hardware should be checked for proper torque before

proceeding to next module.

a. Connecting the module to the base will require four 3/8-16

x 1.25" bolts. One bolt for the front and one bolt for the

rear required for each base. Consult “Hardware Torque

Requirements” (pg b.4) for proper torque values.

b. Connect the modules to each other with eight 3/8-16 x

1.25

"

bolts & dragon tooth washers. Four for the front and

four in the rear of each module. Procedure to be repeated

until all modules are installed. Consult “Hardware Torque

Requirements” (pg b.14) for proper torque values.