Data Industrial Series 340 Btu transmitter Owner’s Manual

2

Se

ns

or I

np

ut

Power Out

Signal

+

Signal

-

Shield

Po

w

er I

n

AC L/DC

+

AC C/DC

-

Ou

tp

ut

Pulse Out

-

Pulse Out

+

Te

m

p 2

Te

m

p 1

Output LED

Model: 340

S/N 340-XXXXX

®

Input LED

Mattapoisett, MA 02739

D.I

.C

.

Co

m

m

Po

rt

1.60”

(40.6mm)

3.65”

(92.7mm)

2.95”

(74.9mm)

.88”

(22mm)

.60”

(15mm)

4.5”

4.50”

2.00

”

Side

Top

Sid

e

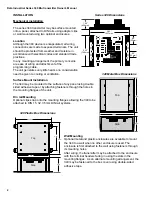

INSTALLATION

Mechanical installation

The series 340 transmitter may be surface mounted

onto a panel, attached to DIN rails using adapter clips

or wall mounted using two optional enclosures.

Location

Although the 340 device is encapsulated, all wiring

connections are made to exposed terminals. The unit

should be protected from weather and moisture in

accordance with electrical codes and standard trade

practices.

In any mounting arrangement, the primary concerns

are ease of wiring and attachment of the

programming cable.

The unit generates very little heat so no consideration

need be given to cooling or ventilation.

Surface Mount Installation

The 340 may be mounted to the surface of any panel using double

sided adhesive tape or by attaching fasteners through the holes in

the mounting flanges of the unit.

Din rail Mounting

Optional clips snap onto the mounting flanges allowing the 340 to be

attached to DIN 15, 32, 35 mm DIN rail systems.

Wall Mounting

Optional metal and plastic enclosures are available to mount

the 340 to a wall when no other enclosure is used. The

enclosure is first attached to the wall using fasteners through

its mounting holes.

After wiring, the transmitter may be attached to the enclosure

with the terminal headers facing in using the slots in the

mounting flanges. As an alternate mounting arrangement, the

340 may be fastened to the box cover using double-sided

adhesive tape.

Series 340 Dimensions

340 Metal Box Dimensions

4.60”

4.60”

2.25

”

Side

Top

Sid

e

3.25”

5.125”

340 Plastic Box Dimensions