NOTICE

•

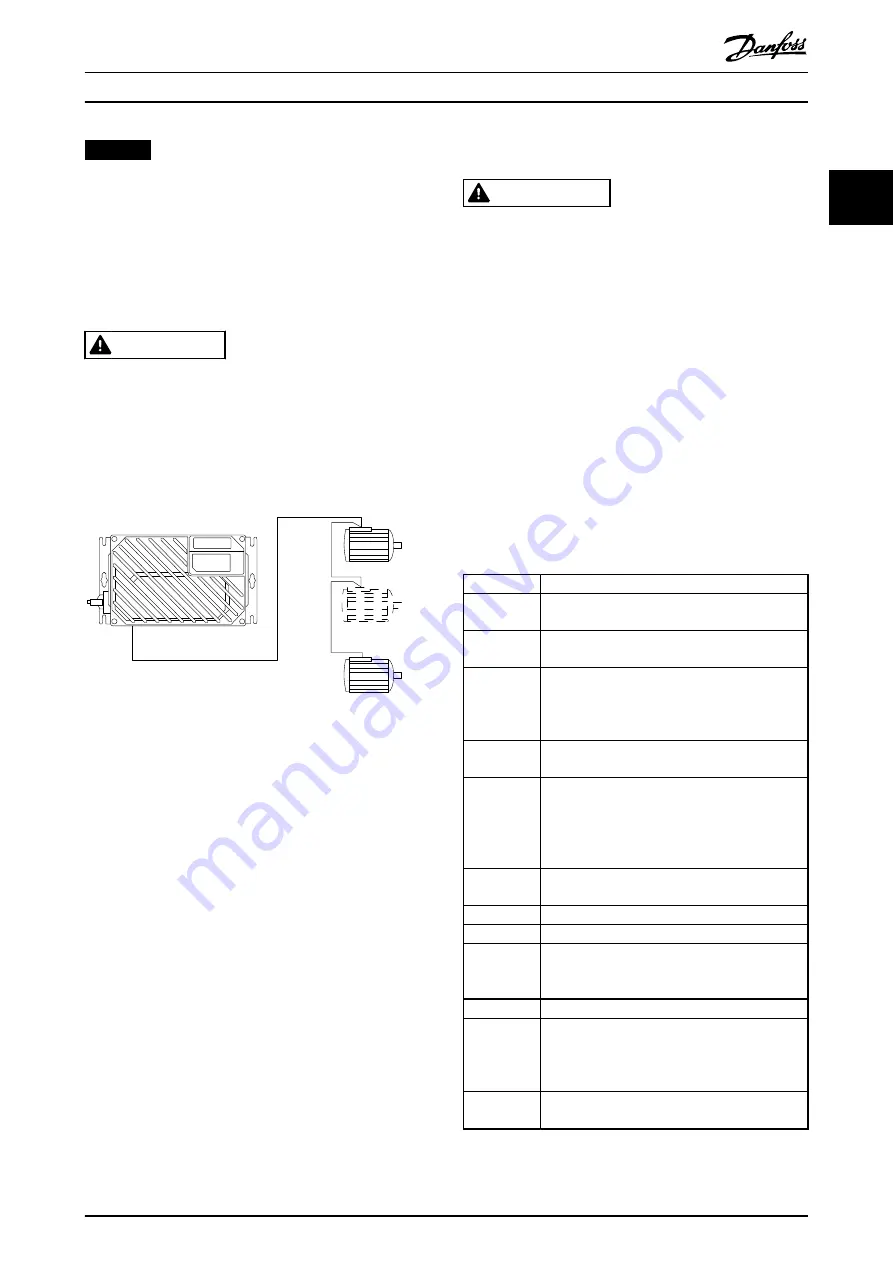

Installations with cables connected in a

common joint as in

, is only

recommended for short cable lengths

(maximum 10 m (32.8 ft)).

•

When motors are connected in parallel,

parameter 1-29 Automatic Motor Adaptation

(AMA)

cannot be used.

CAUTION

INSUFFICIENT MOTOR PROTECTION

The electronic thermal relay (ETR) of the frequency

converter cannot be used as motor protection for the

individual motor in systems with parallel-connected

motors. Provide further motor protection by thermistors

in each motor or individual thermal relays. Circuit

breakers are not suitable as protection.

130BB706.10

Illustration 2.15 Parallel Connection of Motors

Problems can arise at start-up and at low RPM values,

when motor sizes differ widely. Motors of low rated motor

power have a relatively high ohmic resistance in the stator.

This high resistance calls for a higher voltage at start and

at low RPM values. To resolve such a problem:

•

reduce the load during startup, on the motor of

lowest rated motor power

•

configure parallel connections only between

motors of comparable rated motor power

2.4.5 Control Wiring

WARNING

UNINTENDED START

When frequency converter is connected to AC mains

input power, the motor can start at any time. The

frequency converter, motor, and any driven equipment

must be in operational readiness. Failure to be in

operational readiness when the frequency converter is

connected to AC mains could result in death, serious

injury, equipment, or property damage.

•

It is recommended that control wiring is rated for

600 V.

•

Isolate control wiring from high-power

components in the frequency converter.

•

If the frequency converter is connected to a

thermistor, for PELV isolation, ensure control

wiring is reinforced/double insulated.

•

See

chapter 8.2 General Specifications

for control

terminal wiring sizes and maximum loads.

Terminal No. Function

01, 02, 03

Relay 1 output. Useable for AC or DC voltage and

resistive or inductive loads.

04, 05, 06

Relay 2 output. Useable for AC or DC voltage and

resistive or inductive loads.

12, 13

24 V DC digital supply voltage. Useable for digital

inputs and external transducers. To use the 24 V

DC for digital input common, programme

parameter 5-00 Digital I/O Mode

for PNP operation.

18, 19, 32, 33 Digital inputs. Selectable for NPN or PNP function

in

parameter 5-00 Digital I/O Mode

. Default is PNP.

27, 29

Digital inputs or outputs. Programmable for either

parameter 5-01 Terminal 27 Mode

for terminal 27

and

parameter 5-02 Terminal 29 Mode

for 29

selects input/output function. Default setting is

input.

35

Common (-) for external 24 V control back up

supply. Optional.

36

Ex 24 V control back up supply. Optional.

37

Safe Stop. See Safe Stop installation for details.

20

Common for digital inputs. To use for digital input

common, programme

parameter 5-00 Digital I/O

Mode

for NPN operation.

39

Common for analog output.

42

Analog output. Programmable for various

functions in parameter group 6-5*. The analog

signal is 0-20 mA or 4-20 mA at a maximum of

500

Ω

.

50

10 V DC analog supply voltage. 15 mA maximum

commonly used for a potentiometer or thermistor.

Installation

Operating Guide

MG04F402

Danfoss A/S © 05/2016 All rights reserved.

19

2

2