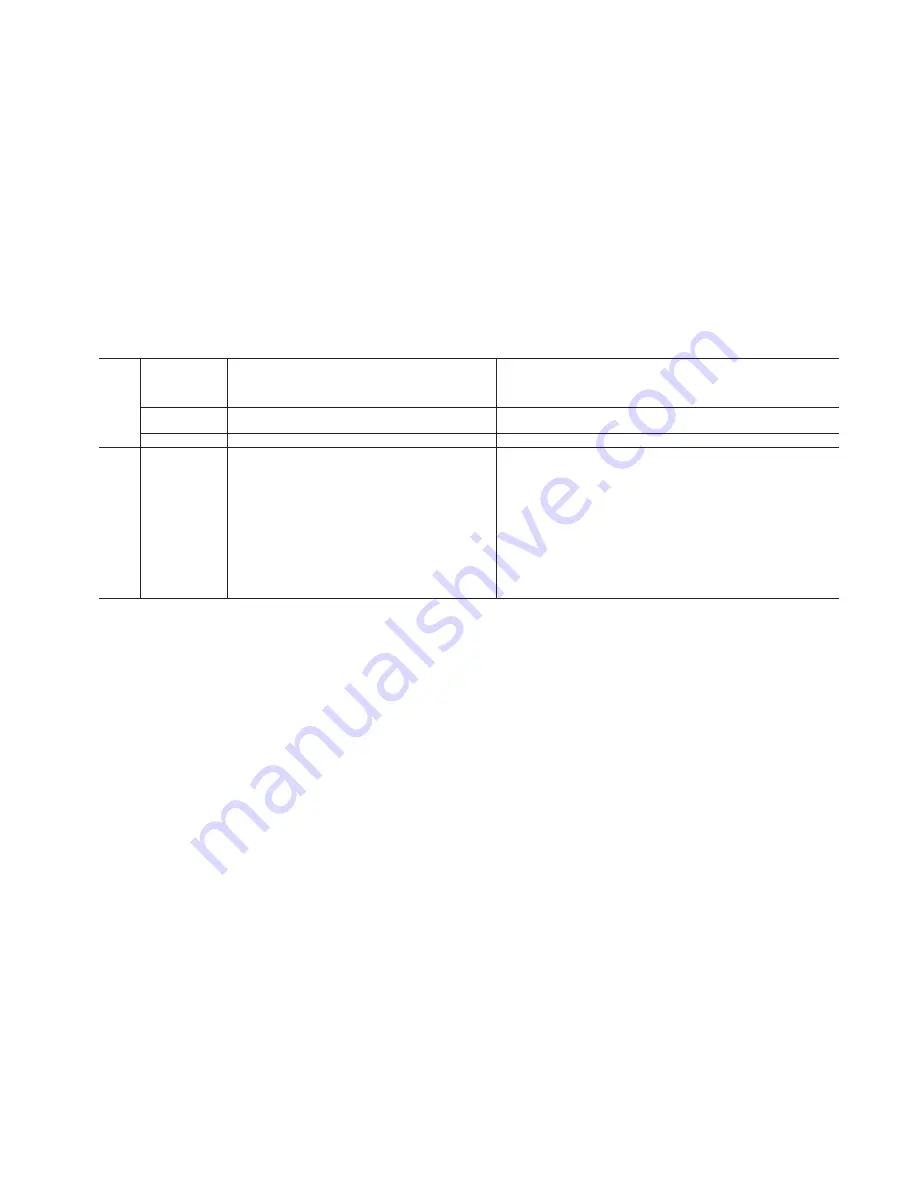

23

The calculation is based on PVC or XLPE insulated cables

with copper or aluminium core. A maximum ambient

temperature of 40°C has been taken into account. The given

wire length limits the voltage drop to < 5%.

IMPORTANT: Before connection of the main power cables (L1

- L2 - L3) on the terminal block, it is imperative to check the

correct order of the 3 phases before proceeding to the

connection on then terminal block or the main disconnect/

isolator switch.

6.4.2 - On-site control wiring

Selection of minimum and maximum wire sections for connection to BW10 units

BW10

Max. connectable

section*

Calculation favourable case:

Suspended aerial lines (standardised routing No. 17)

PVC insulated cable

Calculation unfavourable case:

Conductors in conduits or multi-conductor cables in closed conduit

(standardised routing No. 41)

PVC insulated cable, if possible

Section

Section**

Max. length for

voltage drop <5%

Cable type

Section**

Max. length for voltage drop

<5%

Cable type***

mm² (per phase)

mm² (per phase)

m

mm² (per phase)

m

20

1 x 35

1 x 2.5

60

PVC Cu

1 x 4

100

PVC Cu

25

1 x 35

1 x 2.5

60

PVC Cu

1 x 4

100

PVC Cu

30

1 x 35

1 x 4

80

PVC Cu

1 x 6

120

PVC Cu

35

1 x 35

1 x 4

80

PVC Cu

1 x 6

120

PVC Cu

40

1 x 35

1 x 6

100

PVC Cu

1 x 10

150

PVC Cu

45

1 x 35

1 x 6

100

PVC Cu

1 x 10

150

PVC Cu

50

1 x 35

1 x 10

120

PVC Cu

1 x 16

180

PVC Cu

60

1 x 35

1 x 10

120

PVC Cu

1 x 16

180

PVC Cu

70

1 x 35

1 x 16

140

PVC Cu

1 x 25

205

PVC Cu

80

1 x 35

1 x 16

140

PVC Cu

1 x 25

205

PVC Cu

90

1 x 35

1 x 25

170

PVC Cu

1 x 35

225

PVC Cu

6.4.1 - Field control wiring

Refer to the BW10 Control manual and the certified wiring

diagram supplied with the unit for the field control wiring of

the following features:

•

Remote on/off switch

•

Remote heat/cool switch

•

Demand limit external switch 1

•

Remote dual set point

•

Alarm report

•

Pump control - unit without hydronic module.

•

Relief boiler or electric heater

•

Valve control (refer to the description of options 153 and 154

in the BW10 Control manual)

7 - WATER CONNECTIONS

For size and position of the heat exchanger water inlet and

outlet connections refer to the certified dimensional drawings

supplied with the unit. The water pipes must not transmit any

radial or axial force to the heat exchangers nor any vibration.

The water supply must be analysed and appropriate filtering,

treatment, control devices, isolation and bleed valves and

circuits built in, to prevent corrosion, fouling and deteriora-tion

of the pump fittings. Consult either a water treatment specialist

or appropriate literature on the subject.

7.1 - Operating precautions

The water circuit should be designed to have the least number

of elbows and horizontal pipe runs at different levels. Below the

main points to be checked for the connection:

•

Comply with the water inlet and outlet connections shown

on the unit.

•

Install manual or automatic air purge valves at all high

points in the circuit(s).

•

Use a pressure reducer to maintain pressure in the

circuit(s) and install a safety valve as well as an expan-sion

tank. Units with hydronic module include the safety valve

and expansion tank.

•

Install drain connections at all low points to allow the

whole circuit to be drained.

•

Install stop valves, close to the entering and leaving water

connections.

•

Use flexible connections to reduce the transmission of

vibrations.

•

If the insulation provided is not sufficient, insulate the

cold-water piping, after testing for leaks, both to reduce

heat loss and to prevent condensation.

•

Cover the insulation with a vapour barrier. If the external

water piping to the unit is in an area where the ambient

temperature can fall below 0°C, it should be insulated and

an electric heater should be installed on the piping.

NOTE: For units without hydronic module a screen filter

must be installed as close as possible to the heat exchanger and

in a position that is easily accessible for removal and

cleaning. Units with a hydronic module are equipped with this

filter.

The mesh size of the filter must be 1.2 mm. If this filter is not

installed, the plate heat exchanger can quickly become

contaminated at the first start-up, as it takes on the filter

function, and correct unit operation is affected (reduced

water flow due to increased pressure drop).

Before the system start-up verify that the water circuits are

connected to the appropriate heat exchangers (e.g. no reversal

between evaporator and condenser).

Содержание BW10 020-090

Страница 30: ...30...

Страница 42: ...VMGFT102...