24

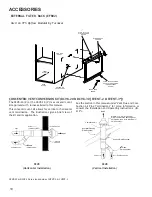

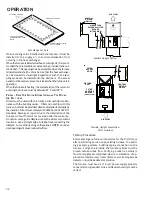

Condensate Drain Lines & Drain Trap

A condensing gas furnace achieves its high level of efficiency by

extracting heat from the products of combustion to the point

where condensation takes place. The condensate must be col-

lected in the furnace drain trap and routed to an appropri-

ate drain location in compliance with local and national codes.

Follow the bullets listed below when installing the drain system.

Refer to the following sections for specific details concerning

furnace drain trap installation and drain hose hook ups.

•

The drain trap supplied with the furnace must be used.

•

The drain trap must be primed at time of installation.

•

The drain line between furnace and drain location must

meet local and nation codes.

•

The drain line between furnace and drain location must

maintain a 1/4 inch per foot downward slope toward the

drain.

•

Do not trap the drain line in any other location than at the

drain trap supplied with the furnace.

•

If the drain line is routed through an area which may see

temperatures near or below freezing, precautions must

be taken to prevent condensate from freezing within the

drain line.

•

If an air conditioning coil is installed with the furnace, a

common drain may be used. An open tee must be in-

stalled in the drain line, near the cooling coil, to relieve

positive air pressure from the coil’s plenum. This is nec-

essary to prohibit any interference with the function of

the furnace’s drain trap.

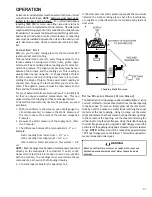

Electrical Connections

HIGH VOLTAGE !

T

O

AVOID

THE

RISK

OF

ELECTRICAL

SHOCK

,

WIRING

TO

THE

UNIT

MUST

BE

POLARIZED

AND

GROUNDED

.

WARNING

HIGH VOLTAGE !

T

O

AVOID

PERSONAL

INJURY

OR

DEATH

DUE

TO

ELECTRICAL

SHOCK

,

DISCONNECT

ELECTRICAL

POWER

BEFORE

SERVICING

OR

CHANGING

ANY

ELECTRICAL

WIRING

.

WARNING

L

ABEL

ALL

WIRES

PRIOR

TO

DISCONNECTION

WHEN

SERVICING

CONTROLS

. W

IRING

ERRORS

CAN

CAUSE

IMPROPER

AND

DANGEROUS

OPERATION

. V

ERIFY

PROPER

OPERATION

AFTER

SERVICING

.

CAUTION

W

IRING

H

ARNESS

The wiring harness is an integral part of this furnace. Field

alteration to comply with electrical codes should not be re-

quired. Wires are color coded for identification purposes.

Refer to the wiring diagram for wire routings. If any of the

original wire as supplied with the furnace must be replaced, it

must be replaced with wiring material having a temperature

rating of at least 105° C. Any replacement wiring must be a

copper conductor.

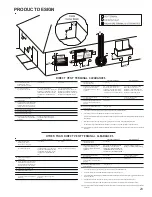

PRODUCT DESIGN