S0103010K

Page 33

Wheel Loader Safety

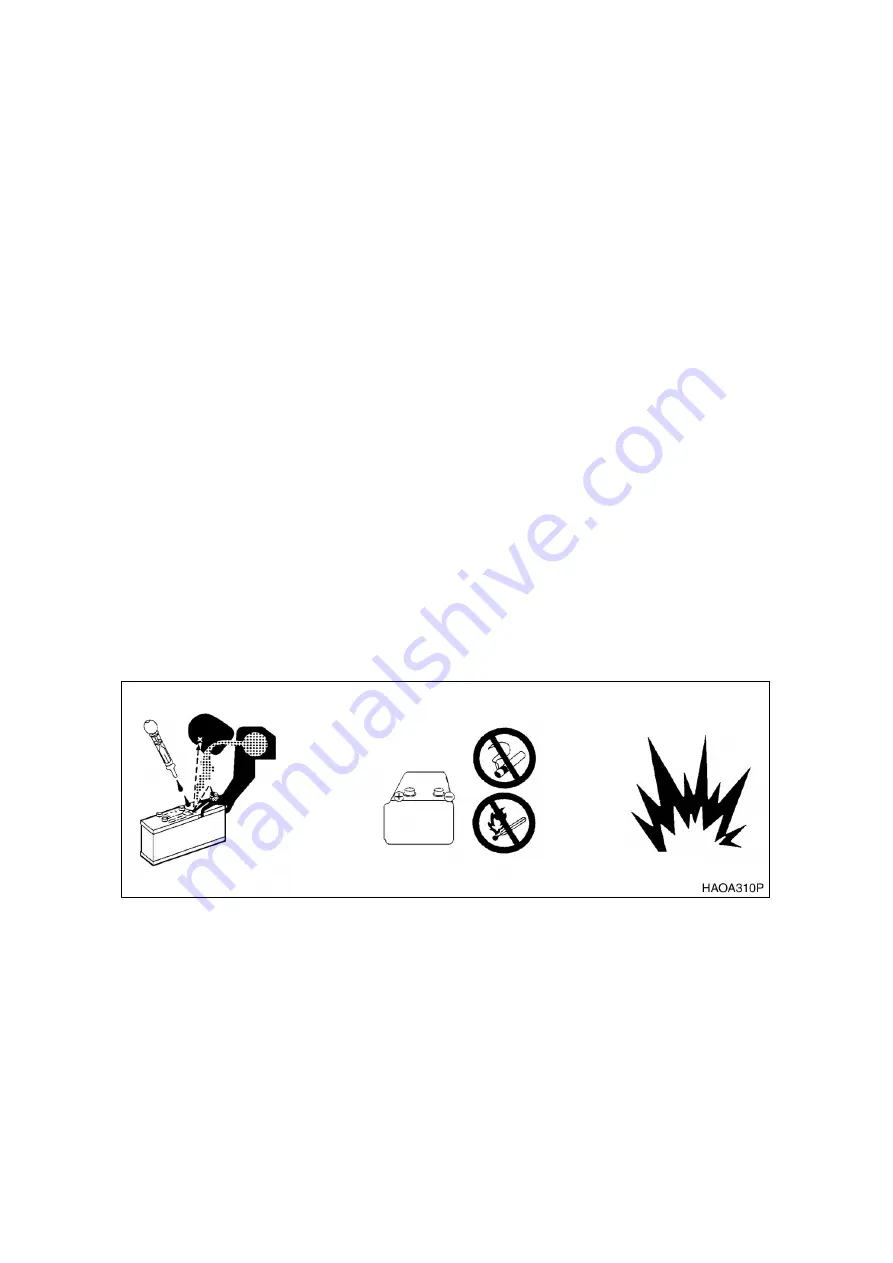

BATTERY

BATTERY HAZARD PREVENTION

Battery electrolyte contains diluted sulfuric acid and batteries generate hydrogen gas. Hydrogen gas is

highly explosive, and mistakes in handling them can cause serious injury or fire. To prevent problems,

always do the following;

•

Do not smoke or bring any flame near the battery.

•

When working with batteries, ALWAYS wear safety glasses and rubber gloves.

•

If you spill battery electrolyte on yourself or your clothes, immediately flush the area with water.

•

If battery electrolyte gets into your eyes, flush them immediately with large quantities of water

and see a doctor at once.

•

If you accidentally drink battery electrolyte, drink a large quantity of water or milk, raw egg or

vegetable oil. Call a doctor or poison prevention center immediately.

•

When cleaning the top surface of the battery, wipe it with a clean, damp cloth. Never use

gasoline, thinner, or any other organic solvent or detergent.

•

Tighten the battery caps securely.

•

Explosive battery gas can be set off by sparks from incidental contact or static discharge. Turn

"OFF" all switches and engine when working on batteries. Keep battery terminals tight. Contact

between a loose terminal and post can create an explosive spark.

•

If the battery electrolyte is frozen, do not charge the battery or start the engine with power from

another source. There is danger that the battery may catch fire.

•

When charging the battery or starting with power from another source, let the battery electrolyte

melt and check that there is no leakage of battery electrolyte before starting the operation.

•

Always remove the battery from the machine before charging.

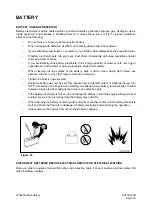

DISCONNECT BATTERIES BEFORE ELECTRICAL SERVICE OR ELECTRICAL WELDING

Remove cable to negative terminal first when disconnecting cable. Connect positive terminal cables first

when installing a battery.

Figure 33

Содержание Mega 500-V

Страница 4: ...1SAFETY ...

Страница 41: ...1SPECIFICATIONS ...

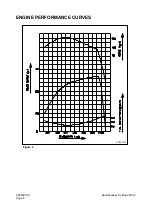

Страница 47: ...S0203070K Page 6 Specifications for Mega 500 V ENGINE PERFORMANCE CURVES AHS3720L Figure 2 ...

Страница 55: ...S0203070K Page 14 Specifications for Mega 500 V ...

Страница 56: ...1GENERAL MAINTENANCE ...

Страница 70: ...S0302000 Page 14 General Maintenance Procedures Return to Master Table of Contents ...

Страница 83: ...1UPPER STRUCTURE ...

Страница 85: ...S0403040K Page 2 Counterweight TABLE OF CONTENTS Specifications 3 Counterweight 3 ...

Страница 87: ...S0403040K Page 4 Counterweight ...

Страница 95: ...S0406040K Page 2 Hydraulic Oil Tank TABLE OF CONTENTS General Description 3 Parts List 3 Specifications 4 ...

Страница 98: ...1LOWER STRUCTURE AND CHASSIS ...

Страница 100: ...S0502020K Page 2 Center Joint Articulation Joint TABLE OF CONTENTS General Description 3 Maintenance Standard 4 ...

Страница 104: ...S0502020K Page 6 Center Joint Articulation Joint ...

Страница 105: ...1ENGINE AND DRIVE TRAIN ...

Страница 117: ...S0602170K Page 12 Axle ZF AP 420R Pinion distance must be decreased Figure 5 Figure 6 Figure 7 Figure 8 ...

Страница 118: ...S0602170K Page 13 Axle ZF AP 420R Figure 9 ...

Страница 119: ...S0602170K Page 14 Axle ZF AP 420R ...

Страница 121: ...S0602170K Page 16 Axle ZF AP 420R FINAL DRIVE AP 407 409 Figure 10 ...

Страница 123: ...S0602170K Page 18 Axle ZF AP 420R AP 411 415 Figure 11 ...

Страница 125: ...S0602170K Page 20 Axle ZF AP 420R AP 417 420 Figure 12 ...

Страница 127: ...S0602170K Page 22 Axle ZF AP 420R DIFFERENTIAL VERSION SCREWED BEARING CAPS Differential Carrier CK Figure 13 ...

Страница 129: ...S0602170K Page 24 Axle ZF AP 420R Differential Carrier RK Figure 14 ...

Страница 131: ...S0602170K Page 26 Axle ZF AP 420R Differential Carrier DK ...

Страница 133: ...S0602170K Page 28 Axle ZF AP 420R DIFFERENTIAL VERSION CAST ON BEARING CAPS Differential Carrier DK Figure 15 ...

Страница 135: ...S0602170K Page 30 Axle ZF AP 420R Differential Carrier HK Figure 16 ...

Страница 178: ...S0602170K Page 73 Axle ZF AP 420R ILLUSTRATED TABLE Figure 152 ...

Страница 194: ...S0602170K Page 89 Axle ZF AP 420R ILLUSTRATED TABLE Figure 196 ...

Страница 210: ...S0602170K Page 105 Axle ZF AP 420R ILLUSTRATED TABLE Figure 242 ...

Страница 225: ...S0602170K Page 120 Axle ZF AP 420R ILLUSTRATED TABLE Figure 289 ...

Страница 251: ...S0605050K Page 26 Air Conditioner Return to Master Table of Contents ...

Страница 261: ...S0607080K Page 10 Transmission and Torque Converter ZF 4WG 310 Figure 2 ...

Страница 264: ...S0607080K Page 13 Transmission and Torque Converter ZF 4WG 310 ...

Страница 271: ...S0607080K Page 20 Transmission and Torque Converter ZF 4WG 310 ...

Страница 291: ...S0607080K Page 40 Transmission and Torque Converter ZF 4WG 310 INSTALLATION VIEW INNER SECTION Figure 36 ...

Страница 296: ...S0607080K Page 45 Transmission and Torque Converter ZF 4WG 310 ...

Страница 447: ...S0607900C Page 36 Transmission Error Codes ZF ...

Страница 448: ...1HYDRAULICS ...

Страница 478: ...S0705010 Page 22 Cylinders Return to Master Table of Contents ...

Страница 489: ...S0708460K Page 11 Main Pump Denison T6DMY Series ...

Страница 490: ...S0708460K Page 12 Main Pump Denison T6DMY Series PARTS LIST Figure 8 ...

Страница 504: ...S0708460K Page 26 Main Pump Denison T6DMY Series ...

Страница 508: ...S0708470K Page 4 Steering and Brake Pump Denison T67DB Series PARTS LIST Figure 2 ...

Страница 514: ...S0708470K Page 10 Steering and Brake Pump Denison T67DB Series DISASSEMBLY Figure 5 ...

Страница 521: ...S0708470K Page 17 Steering and Brake Pump Denison T67DB Series ...

Страница 522: ...S0708470K Page 18 Steering and Brake Pump Denison T67DB Series REASSEMBLY Figure 15 ...

Страница 528: ...S0708470K Page 24 Steering and Brake Pump Denison T67DB Series ...

Страница 548: ...S0709476K Page 2 Pilot Control Valve Return to Master Table of Contents ...

Страница 554: ...S0709476K Page 8 Pilot Control Valve Return to Master Table of Contents ...

Страница 557: ...S0709665K Page 3 Flow Amplifier Danfoss GENERAL DESCRIPTION Figure 1 ...

Страница 558: ...S0709665K Page 4 Flow Amplifier Danfoss PARTS LIST Figure 2 ...

Страница 561: ...S0709665K Page 7 Flow Amplifier Danfoss TROUBLESHOOTING TESTING AND ADJUSTMENT Figure 4 Flow Amplifier Circuit ...

Страница 582: ...S0709665K Page 28 Flow Amplifier Danfoss H Shock valve suction valve shown dismantled Figure 63 ...

Страница 609: ...S0709730K Page 7 Power Steering Unit Return to Master Table of Contents ...

Страница 632: ...S0709730K Page 30 Power Steering Unit Return to Master Table of Contents ...

Страница 638: ...S0709750K Page 6 Restriction Valve Return to Master Table of Contents ...

Страница 642: ...S0793060K Page 4 Hydraulic Schematic Mega 500 V Return to Master Table of Contents MEGA 500 V Figure 2 ...

Страница 644: ...S0793060K Page 6 Hydraulic Schematic Mega 500 V Return to Master Table of Contents ...

Страница 645: ...1ELECTRICAL SYSTEM ...

Страница 654: ...S0802190K Page 9 Electrical System Return to Master Table of Contents ...

Страница 658: ...S0802190K Page 13 Electrical System Return to Master Table of Contents ...

Страница 676: ...S0802190K Page 31 Electrical System Return to Master Table of Contents ...

Страница 683: ...S0893060K Page 4 Electrical Schematic Mega 500 V Return to Master Table of Contents MEGA 500 V Figure 2 ...

Страница 684: ...S0893060K Page 5 Electrical Schematic Mega 500 V Return to Master Table of Contents AHS3680L MEGA 500 V ...

Страница 685: ...S0893060K Page 6 Electrical Schematic Mega 500 V Return to Master Table of Contents ...

Страница 686: ...1ATTACHMENTS ...