24

34

3. Cleaning the Nozzle

The Nozzle will slowly accumulate bits of filament on the outside from picking up wisps, the filament curling especially when first bit

is extruded.... over time these will become hard and may stick out and make contact with the extruded filament pulling it along the

build plate.

So heat the nozzle and using a thick cloth, to avoid burning your fingers, make sure the outside is clean.

The inside of the nozzle can also become clogged due to impurities in the filament, the filament deteriorating as it cools.......

If so then this can reduce the filament flow, sometimes irregularly, resulting in thinner lines and debris in the filament.

To clean the nozzle:

● Heat it to at least the filament printing temperature, preferably to 260˚

●

Remove the filament completely.

●

Carefully clean the outside of the nozzle and gently clean the silicon cover around it.

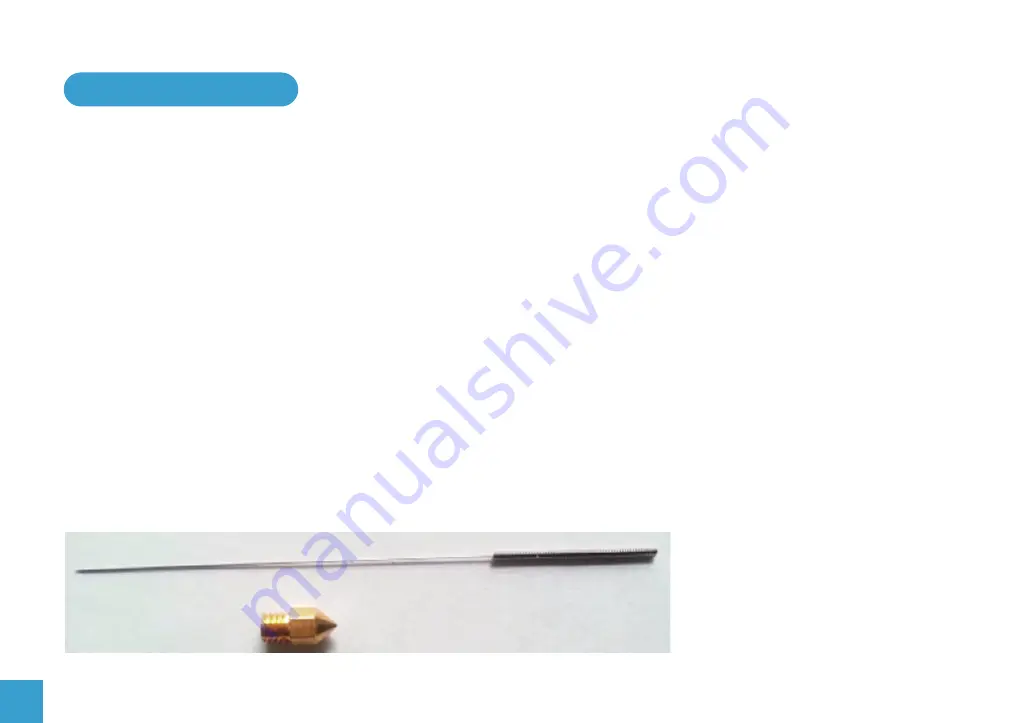

● Use a correctly sized cleaning needle for the nozzle (the one included is for the standard 0.4mm nozzle)

and insert into the hot nozzle to clean it out and dislodge any blockage.

●

Trim the bottom inch off the filament and re insert it.

●

Extrude a few centimetres of filament to flush anything out.

If this doesn’t cure the problem repeat the process. If that doesn’t work consider changing the nozzle for a new one.