Installation 6

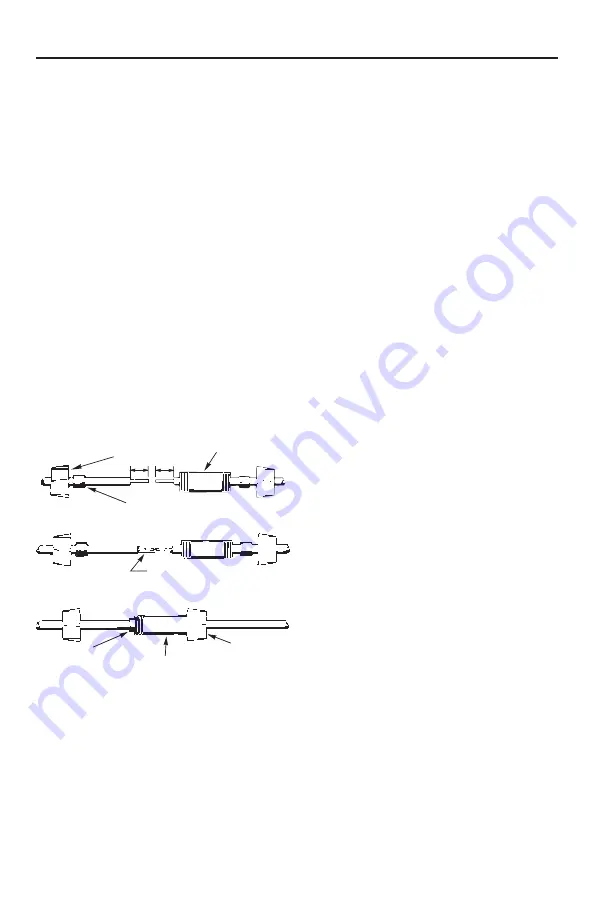

Butt connectors with plastic insulators - For

wire sizes AWG 14, 12 and 10 (2, 3, and

5.5mm²):

1. Cut off motor leads. Stagger lead and wire

length so that 2nd lead is 4” (100mm) longer

than 1st lead and 3rd lead is 4” (100mm)

longer than second.

2. Cut off cable ends. Be sure to match colors

and lengths of wires in drop cable to colors

and lengths of motor leads.

3. Trim insulation back 1/2” (13mm) from cable

ends and motor lead ends.

4. Unscrew plastic caps from insulators. Place a

cap and a neoprene gasket sleeve on each wire

end to be spliced (see Figure 7).

5. Slide insulator body onto one wire end

(Figure 7).

6. Insert wire end into butt connector and crimp

(see Figure 8). Be sure to match cable and

motor wire colors.

7. Center insulator body over splice and slide

neoprene sleeves into body as far as they

will go. Screw caps onto insulator body

(Figure 9) and tighten by hand for a strong,

waterproof splice.

Po wer Supply Cable Installation

1. To test submersible pump, momentarily

connect it to proper power supply. Power

supply frequency and voltage must match

motor nameplate frequency and voltage to

within ±10%.

2. Fasten cable leads securely to pump discharge

section; leave 4-5” (100-127mm) of slack in

leads at this point. Securely fasten leads to

plastic pipe within 6” (150mm) of the pump

discharge section. Use properly-installed

torque arresters to protect pump and pipe from

twisting damage as pump starts and stops.

3. A copper ground wire at least as large as

wires supplying current to the motor must

be connected in designated location. Most

submersible motors will include a ground

lead for connection. Other motors will have

designated location on motor bracket.

4. Use only submersible cable supplied by pump

manufacturer. When lowering pump into well,

secure cable to discharge pipe at 10’ (3.5m)

intervals with electrical tape. Take care not to

damage pump cable.

NOTICE To avoid dropping the pump down

the well or damaging cable or cable splices,

NEVER allow pump cable to support weight

of pump.

Pump Installation

1. If a standard air over water pressure tank is

being used, install two bleeder orifices about

2’ (60cm) apart as shown in Figure 11. These

orifices will automatically charge the tank with

air. See Figure 11 to determine orifice location.

NOTICE If a pre-charged tank is used, DO

NOT install bleeder orifices. If pump and

pre-charged tank are replacing a standard

tank system, remove bleeder orifices before

installing pump in well.

2. To prevent losing pump down the well,

connect a safety rope strong enough to support

pump and drop pipe (minimum 5/16” [8mm]

twisted polypropylene or synthetic manila

rope) through eyelet, around pump discharge.

Tie off other end of safety rope securely to well

seal, well cap or pitless adapter.

3. Discharge outlet is 1-1/4” NPT threaded.

Use 100 PSI (689.5kPa) rated polyethylene

plastic pipe for installations up to

100’ (30.5M) depth.

Use 160 PSI (1103.2 kPa) rated

polyethylene plastic for installations up to

220’ (67.1M) depth.

For depths beyond 220’ (67.1M) use

galvanized steel pipe for the entire drop pipe.

Insulator body centered over splice

Gasket sleeve in place

Cap screwed on

Butt connector or

crimp or solder

6469 1111

End cap

Gasket

Insulator body

1/2”

(12.7mm)

Figure 7

Figure 8

Figure 9

Содержание 102890199

Страница 24: ......