32

COMUNELLO

®Copyright 2016 - All rights reserved

10.4 PROGRAMMING:

SEL key:

selects the type of function to store; the selection is indicated by

blinking of the LED.

Press the key repeatedly to go to the required function. The selection

remains active for 10 seconds shown by blinking of the LED; when this

interval elapses the control unit returns to the original state.

SET key:

programs the information in accordance with the function type

preselected with the SEL key.

IMPORTANT:

The SET key function can be replaced by the remote if

programmed beforehand (CODE LED on).

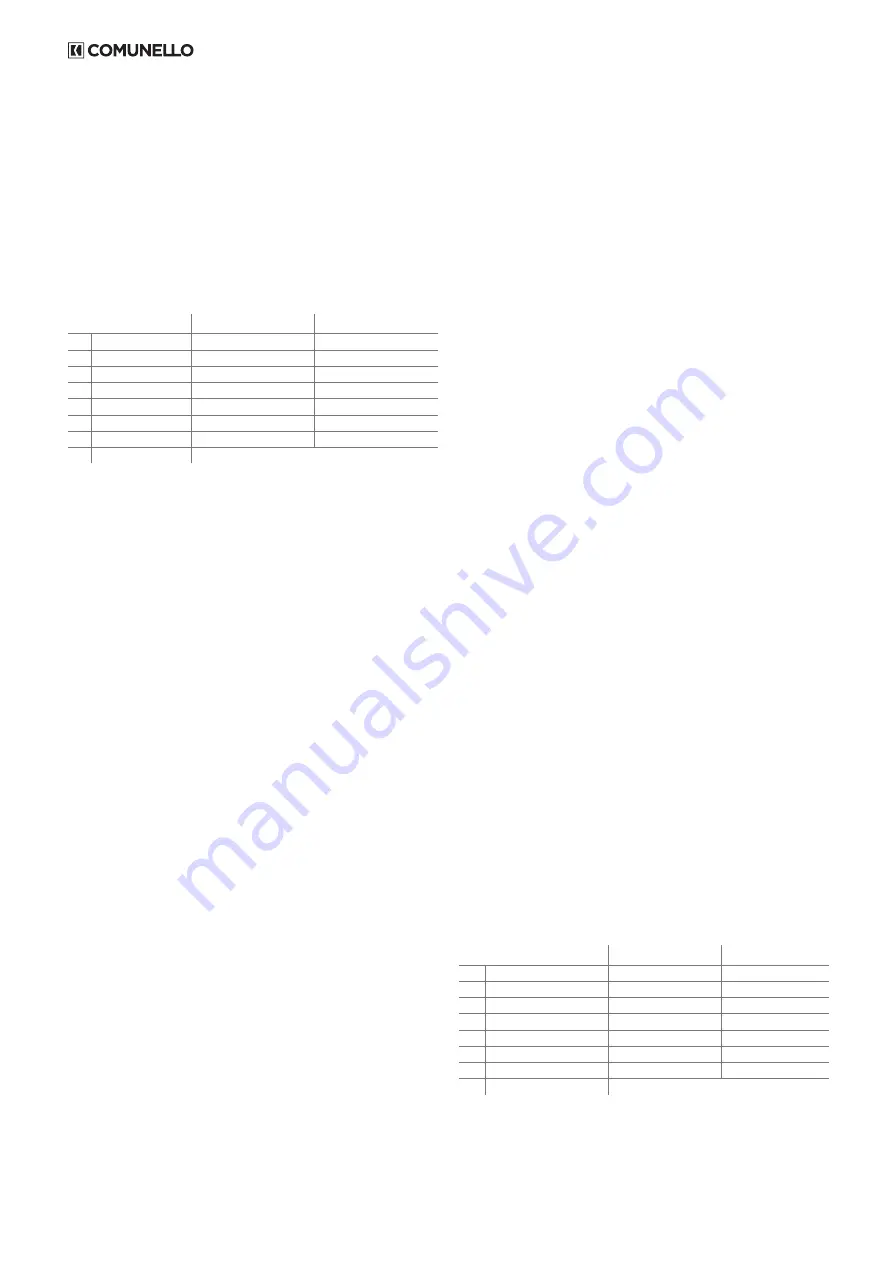

MAIN MENU

The control unit is factory set to allow selection of several important

functions.

LED OFF

LED ON

L1

TX CODE

No code

Code entered

L2

MOTOR TIME

Factory T. setting

Programmed time

L3

PAUSE TIME

Without aut.close

With automatic close

L4

FORCE OPEN

Maximum

Med – min set by speed

L5

FORCE CLOSE

Maximum

Med – min set by speed

L6

SLOWING OPEN

Maximum

Med – min set by slowing

L7

SLOWING CLOSE

Maximum

Med – min set by slowing

LEV MENU

ON

1. CODE (Remote control code):

Up to 120 remotes with different codes of either the fixed or rolling code

type can be saved on the control unit.

Programming.

The transmission code is programmed as follows: use the SEL key to

select blinking LED L1 and transmit the chosen code with the required

remote within 10 seconds; LED L1 will remain steady on to indicate that

programming has been completed.

If all 120 codes have been saved, repeating the programming operation will

cause all the programming LEDs to start blinking to signal that no further

codes can be saved.

Remote controls reset.

To delete all the previously saved remotes from the receiver, use SEL to

select LED L1, then press SET and hold it pressed for > 5 s. At the end

of this interval the LED will switch off for two seconds to confirm that the

procedure has been completed successfully.

Rule of the first saved Remote control:

When programming remotes the following rule is applied: if the first remote

to be saved is a rolling code type, the receiver will subsequently accept only

rolling code remotes, thus providing enhanced anti-intrusion security; if the

first remote to be saved is a fixed code type, the receiver will subsequently

accept both fixed code remotes and rolling code remotes.

WARNING:

Whenever you reset the remotes on the receiver, all the saved

remotes will be deleted and also the rule of the first saved remote control

will be reset to default.

2. MOTOR TIME (Barrier working time programming):

The control unit is factory set with a standard work profile for a barrier with

a 5 m arm. If the Operator working time and slowing stages duration must

be changed, reprogramming must be performed with the barrier closed

as follows: use the SEL key to select blinking LED L2 and then press the

SET key momentarily; the Operator will start an Opening cycle; when the

required slowdown starting point is reached, press the SET key again;

LED L2 will start blinking more slowly and the Operator will decelerate; on

reaching the required position press SET to terminate the Opening cycle.

When Opening cycle time programming is completed, the Operator restarts

immediately in the Closing cycle: repeat the operations described above for

the Closing cycle.

WARNING:

The barrier working time function must be set with sensitivity

setting higher than 50% and at reduced speed.

3. PAUSE TIME (Automatic closing time programming 4 min. max.):

The control unit is factory set with automatic closing disabled. If you wish

to enable automatic closing proceed as follows: use the SEL key to select

blinking LED L3 and press the SET key momentarily; now wait for a time

equivalent to the required time; press the SET key again momentarily

and at the same time the automatic closing time will be saved and LED

L3 will remain steady on. If you wish to restore the initial condition (no

automatic closing) select blinking LED L3 and then press the SET key twice

consecutively in an interval of 2 seconds. The LED will switch off and the

operation will be completed.

4. FORCE OPEN (Selecting the Force profile in the Normal Opening

cycle):

The control unit allows you to define different operator Force profiles during

the Normal operating cycle in the Opening movement. In the factory set

configuration, operator Force during opening is set at the maximum level

“MAX” (i.e. identical to the setting selected using the SPEED trimmer with

LED L4 off); if you wish to change the profile to a medium level value “MED”,

proceed as follows: use the SEL key to select blinking LED L4 and press the

SET key; at the same time LED L4 becomes steady on and programming

will be completed. If you wish to change the profile to a Minimum value

“MIN” repeat the operation described above, pressing the SEL key twice

(LED L4 will blink rapidly) rather than once. Repeat the procedure if you wish

to restore the initial configuration.

5. FORCE CLOSE (Selecting the Force profile in the Normal Closing

cycle):

The control unit allows you to define different operator Force profiles during

the Normal operating cycle in the Closing movement. In the factory set

configuration, operator Force during closing is set at the maximum level

“MAX” (i.e. identical to the setting selected using the SPEED trimmer with

LED L5 off); if you wish to change the profile to a medium level value “MED”

proceed as follows: use the SEL key to select blinking LED L5 and press the

SET key; at the same time LED L5 becomes steady on and programming

will be completed. If you wish to change the profile to a Minimum value

“MIN” repeat the operation described above, pressing the SEL key twice

(LED L5 will blink rapidly) rather than once. Repeat the procedure if you wish

to restore the initial configuration.

6. SLOWING OPEN (Selecting the Force profile in the Opening

Slowdown cycle):

The control unit allows you to define different operator Force profiles during

the Slowdown operating cycle in the Opening movement. In the factory set

configuration, operator Force during the opening slowdown stage is set at

the maximum level “MAX” (i.e. identical to the setting selected using the

SLOWING trimmer with LED L6 off); if you wish to change the profile to a

medium level value “MED” proceed as follows: use the SEL key to select

blinking LED L6 and press the SET key; at the same time LED L6 becomes

steady on and programming will be completed. If you wish to change the

profile to a Minimum value “MIN” repeat the operation described above,

pressing the SEL key twice (LED L6 will blink rapidly) rather than once.

Repeat the procedure if you wish to restore the initial configuration.

7. SLOWING CLOSE (Selecting the Force profile in the Closing

Slowdown cycle):

The control unit allows you to define different operator Force profiles during

the Slowdown operating cycle in the Closing movement. In the factory set

configuration, operator Force during the closing slowdown stage is set at

the maximum level “MAX” (i.e. identical to the setting selected using the

SLOWING trimmer with LED L7 off); if you wish to change the profile to a

medium level value “MED” proceed as follows: use the SEL key to select

blinking LED L7 and press the SET key; at the same time LED L7 becomes

steady on and programming will be completed. If you wish to change the

profile to a Minimum value “MIN” repeat the operation described above,

pressing the SEL key twice (LED L7 will blink rapidly) rather than once.

Repeat the procedure if you wish to restore the initial configuration.

EXTENDED MENU 1

The control unit is factory set to allow direct selection exclusively of the main

menu functions.

If you wish to enable the functions described in Extended Menu 1, proceed

as follows: select blinking LED LEV and press SET 1 times. The LED will

start blinking alternately 1 0 1 0 1 0. This means you have 30 seconds to

select the functions of Extended Menu 1 using the SEL and SET keys;

once an additional 30 seconds have elapsed, the control unit reverts to

the main menu.

LED OFF

LED ON

L1

REMOTE PROGRAMMING

OFF

ON

L2

PUSHBUTTONS PUL

PUL=AP/CH

PUL=CH

L3

AUTO PROGRAM

UNSCHEDULED TIME

PROGRAMMED TIME

L4

FOTO TEST

OFF

ON

L5

DO NOT USE

DO NOT USE

DO NOT USE

L6

DO NOT USE

DO NOT USE

DO NOT USE

L7

NC AS 8K2

OFF

ON

LEV

MENU

1 FLASH

1. REMOTE RADIO CONTROL PROGRAMMING:

The control unit allows the transmission code to be programmed remotely

without acting directly on the control unit SEL key.

Remote programming of a Radio remote control is performed as follows:

send the code of a previously saved remote continuously for more than 10

seconds; at the same time the control unit switches to programming mode

Содержание LIMIT 500

Страница 3: ...3 COMUNELLO Copyright 2016 All rights reserved FIG 2A FIG 2B FIG 3 FIG 4 FIG 3B FIG 5...

Страница 5: ...5 COMUNELLO Copyright 2016 All rights reserved FIG 7A FIG 7B FIG 8A FIG 8C FIG 8B FIG 9A...

Страница 7: ...7 COMUNELLO Copyright 2016 All rights reserved FIG 13A FIG 13B FIG 14A FIG 14B...

Страница 8: ...8 COMUNELLO Copyright 2016 All rights reserved FIG 16A FIG 16B FIG 15...

Страница 9: ...9 COMUNELLO Copyright 2016 All rights reserved FIG 17 FIG 18A FIG 18B...

Страница 10: ...10 COMUNELLO Copyright 2016 All rights reserved DEFLECTOR FIXING FIG 20A...

Страница 11: ...11 COMUNELLO Copyright 2016 All rights reserved CLIP LED FIXING TO AVOID INTERFERENCES WITH COMPONENTS FIG 20B...

Страница 12: ...12 COMUNELLO Copyright 2016 All rights reserved LIMIT 500 SWING DOWN SUPPORT 45 MIN FIG A FIG C FIG B...

Страница 13: ...13 COMUNELLO Copyright 2016 All rights reserved LIMIT 600 SWING DOWN SUPPORT 45 MIN FIG A FIG C FIG B...

Страница 14: ...LIMIT 800 SWING DOWN SUPPORT 45 MIN FIG A FIG C FIG B...

Страница 16: ...LIMIT 600 BAR AND SKIRT FIG A FIG C FIG B 110 MIN 110 MIN 200 200...

Страница 17: ...17 COMUNELLO Copyright 2016 All rights reserved LIMIT 800 BAR AND SKIRT FIG A FIG C FIG B 110 MIN 110 200 200...

Страница 68: ...NOTES...

Страница 69: ...69 COMUNELLO Copyright 2016 All rights reserved NOTES...

Страница 70: ...NOTES...

Страница 71: ...71 COMUNELLO Copyright 2016 All rights reserved NOTES...