29

COMUNELLO

®Copyright 2016 - All rights reserved

ENGLISH

suitable for residential, public and industrial applications. Thanks to the on-

board electronic control unit any type of barrier system function can be

programmed.

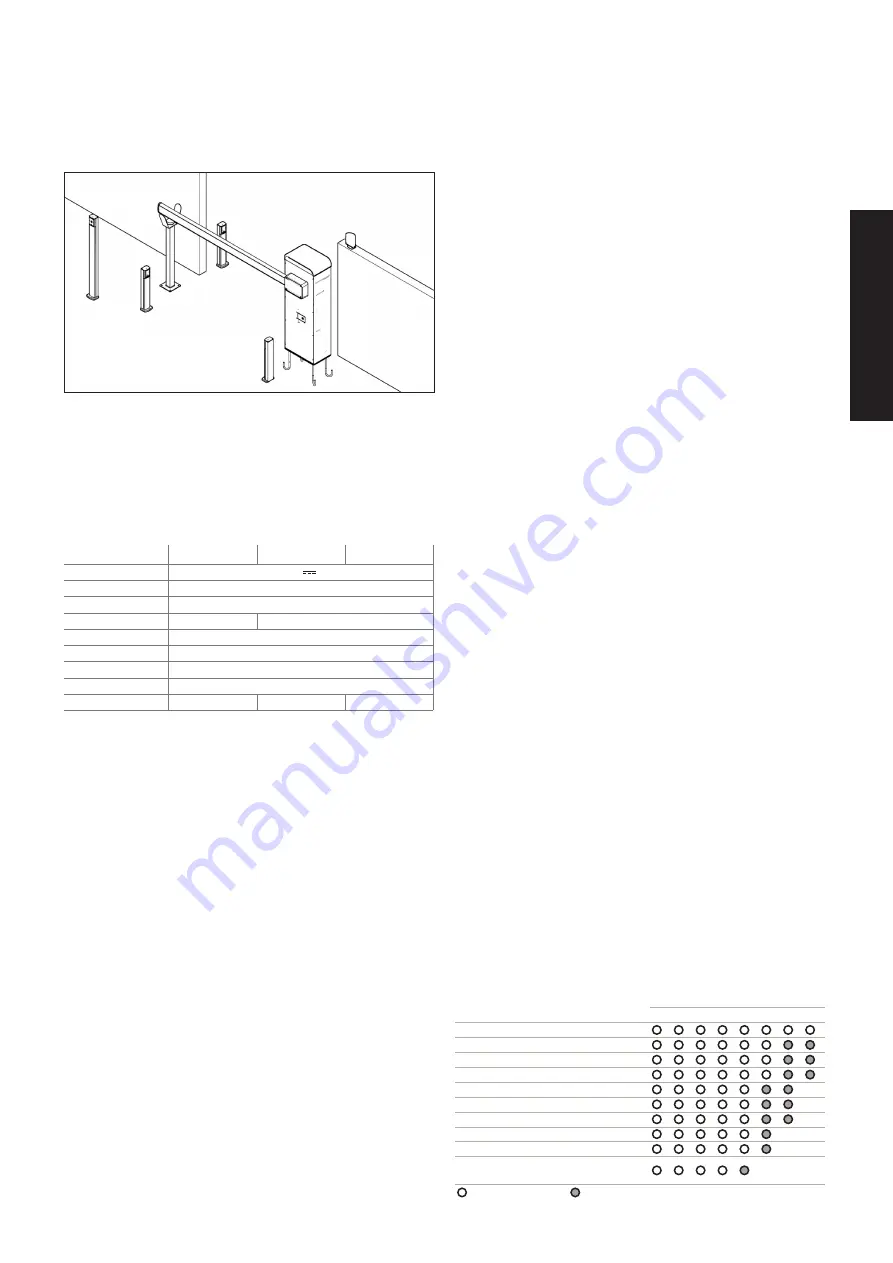

2.2 TYPICAL INSTALLATION

D

E

C

B

B

A

KEY

A BARRIER SYSTEM WITH INTERNAL CONTROL UNIT

B PHOTOCELLS

C FLASHING LIGHT

D KEY SELECTOR SWITCH

E END REST

3 TECHNICAL SPECIFICATIONS

LIMIT 500

LIMIT 600

LIMIT 800

Operator power supply

24 V

Power consumption

150 W

max

Current input

6,5 A

Torque

100 Nm

300 Nm

Duty cycle

Intensive (15” ON - 45” OFF)

Protection rating

IP 24 D

Insulation class

II (2)

Working temperature

from -20°C to + 50°C

Weight

65 Kg

65 Kg

95 Kg

4 INSTALLATION

4.1 PRELIMINARY CHECKS

For correct operation of the automation system, make sure:

• all the accessories are suitably sized and properly maintained.

• all the operating limits of the product can be complied with.

• the minimum and maximum clearances shown in FIG. 1A, FIG. 1B

and FIG. 1C are complied with.

• all material used is in perfect condition and fit for purpose.

• the selected installation site is compatible with the overall dimensions

of the product.

• there are no hindrances that could obstruct the opening and closing

movements of the barrier arm.

• the footing of the barrier system is able to provide stable anchorage

of the unit.

• the space around the barrier system is sufficient to allow easy and

safe execution of manual barrier operations.

• all devices to be installed are in a protected location so as to minimize

the risk of accidental impact.

• If necessary, create a pedestrian entrance well clear of the operating

range of the barrier arm.

4.2 APPLICATION LIMITS

LIMIT 500:

• Use an end rest for arms more than 3 m long

• If you wish to install a skirt, it should be no more than 4 metres long

LIMIT 600/800:

• Use an end rest for arms more than 3 m longo

• If you wish to install a skirt, it should be no more than 7 metres long

LIMIT 500/600/800:

• Before installing the operator check that its specifications are within the

operating limits shown in the chapter “Product Technical Specifications”

4.3 PREPARATORY WORK FOR INSTALLATION

• Assemble counterplate and anchor bolts (FIG. 2A for LIMIT 500, FIG. 2B

for LIMIT 600-800)

• Embed counterplate and anchor bolts in concrete (FIG. 3A)

• In the case of an existing concrete footing drill 4 holes for the screw

anchors as shown in FIG. 3B.

4.4 INSTALLING THE LIMIT BARRIER SYSTEM

4.4.1 INSTALLATION:

• Remove the front cover using the supplied key (FIG. 4)

• Place the pedestal on the counterplate, routing the power and

accessories cables through the cable inlet hole. Secure the pedestal

with the nuts and washers supplied (FIG. 5)

Arm assembly:

• To create an arm of 7 or 8 metres long, assemble 2 sections (available

in 3-4-5 metre lengths)

• When using a round arm (LIMIT 800) use the specific joint as shown in

FIG. 6A

• When using a rectangular section arm (LIMIT 500 and 600) use the

specific joint as shown in FIG. 6B

• Where required, attach the adhesive LED strip in the channel over the

full length of the arm (FIG. 7A)

• Insert the impact protection strip in the specific guides, stopping at a

distance of 175 mm from the opposite end FIG. 7B. The rubber impact

protection strip cannot be fitted on round section arms.

• Secure the end cap to one end of the arm, as shown in FIG. 8A for

LIMIT 500/600 with impact protection strip, FIG. 8B for LIMIT 500/600

without impact protection strip, and FIG. 8C for LIMIT 800. If the arm is

composed of several parts, the end cap must be fitted to the shortest

section.

Installing the arm:

• Release the operator as described in heading 4.4.3

• Fix the arm support to the protruding pivot at the rear of the frame and

ensure it is in the “arm horizontal” position (FIG. 9A) and that the internal

mechanism is in the position shown in FIG. 9C. Smear threadlocker on

the 4 central screws as shown in FIG. 9A and FIG. 9B

• When using a rectangular arm, insert the plates inside the indicated

grooves , as shown in FIG. 9A

• When using a round arm, use the specific support as shown in FIG. 9B

• Make sure the arm is fully inserted into the support.

• Close the support by fitting the cover (FIG. 9A – FIG. 9B).

Assembly of the linkages:

• In the case of LIMIT 600 and LIMIT 800 couple rocker arm A to the drive

shaft via linkages B and C (FIG.10A) appropriately assembled for RH

units (FIG.11A) and LH units (FIG.11B) with the addition of threadlockers

(FIG.10A)

• In the case of LIMIT 500 the linkages are not present.

Fitting the springs:

• If the barrier system is locked, to release it proceed as illustrated in

heading 4.4.3

• Bring the arm to the vertical position (FIG. 12)

• Secure the spring (single or double) at the top and at the bottom as

shown in figures 13A, 13B and 13C

• When installed, make sure the arm is counterbalanced by the spring as

shown in figures 14A and 14B

• Choose the appropriate spring by referring to the following table

LIMIT 500

BAR ASSEMBLY

LENGTH (meters)

AND SPRING CHOICE

1,5 2,0 2,5 3,0 3,5 4,0 4,5 5,0

Bar

Bar with bar cover kit

Bar with bar cover kit and led

Bar with swing down support

Bar with bar cover kit and swing down support

Bar with bar cover kit, led and swing down support

Bar with curtain

Bar with upper bar cover and curtain

Bar with upper bar cover, led and curtain

Bar with upper bar cover,

led, curtain and swing down support

Small spring AC 530 Medium spring AC 540

Содержание LIMIT 500

Страница 3: ...3 COMUNELLO Copyright 2016 All rights reserved FIG 2A FIG 2B FIG 3 FIG 4 FIG 3B FIG 5...

Страница 5: ...5 COMUNELLO Copyright 2016 All rights reserved FIG 7A FIG 7B FIG 8A FIG 8C FIG 8B FIG 9A...

Страница 7: ...7 COMUNELLO Copyright 2016 All rights reserved FIG 13A FIG 13B FIG 14A FIG 14B...

Страница 8: ...8 COMUNELLO Copyright 2016 All rights reserved FIG 16A FIG 16B FIG 15...

Страница 9: ...9 COMUNELLO Copyright 2016 All rights reserved FIG 17 FIG 18A FIG 18B...

Страница 10: ...10 COMUNELLO Copyright 2016 All rights reserved DEFLECTOR FIXING FIG 20A...

Страница 11: ...11 COMUNELLO Copyright 2016 All rights reserved CLIP LED FIXING TO AVOID INTERFERENCES WITH COMPONENTS FIG 20B...

Страница 12: ...12 COMUNELLO Copyright 2016 All rights reserved LIMIT 500 SWING DOWN SUPPORT 45 MIN FIG A FIG C FIG B...

Страница 13: ...13 COMUNELLO Copyright 2016 All rights reserved LIMIT 600 SWING DOWN SUPPORT 45 MIN FIG A FIG C FIG B...

Страница 14: ...LIMIT 800 SWING DOWN SUPPORT 45 MIN FIG A FIG C FIG B...

Страница 16: ...LIMIT 600 BAR AND SKIRT FIG A FIG C FIG B 110 MIN 110 MIN 200 200...

Страница 17: ...17 COMUNELLO Copyright 2016 All rights reserved LIMIT 800 BAR AND SKIRT FIG A FIG C FIG B 110 MIN 110 200 200...

Страница 68: ...NOTES...

Страница 69: ...69 COMUNELLO Copyright 2016 All rights reserved NOTES...

Страница 70: ...NOTES...

Страница 71: ...71 COMUNELLO Copyright 2016 All rights reserved NOTES...