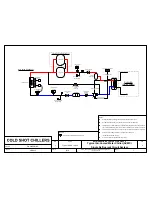

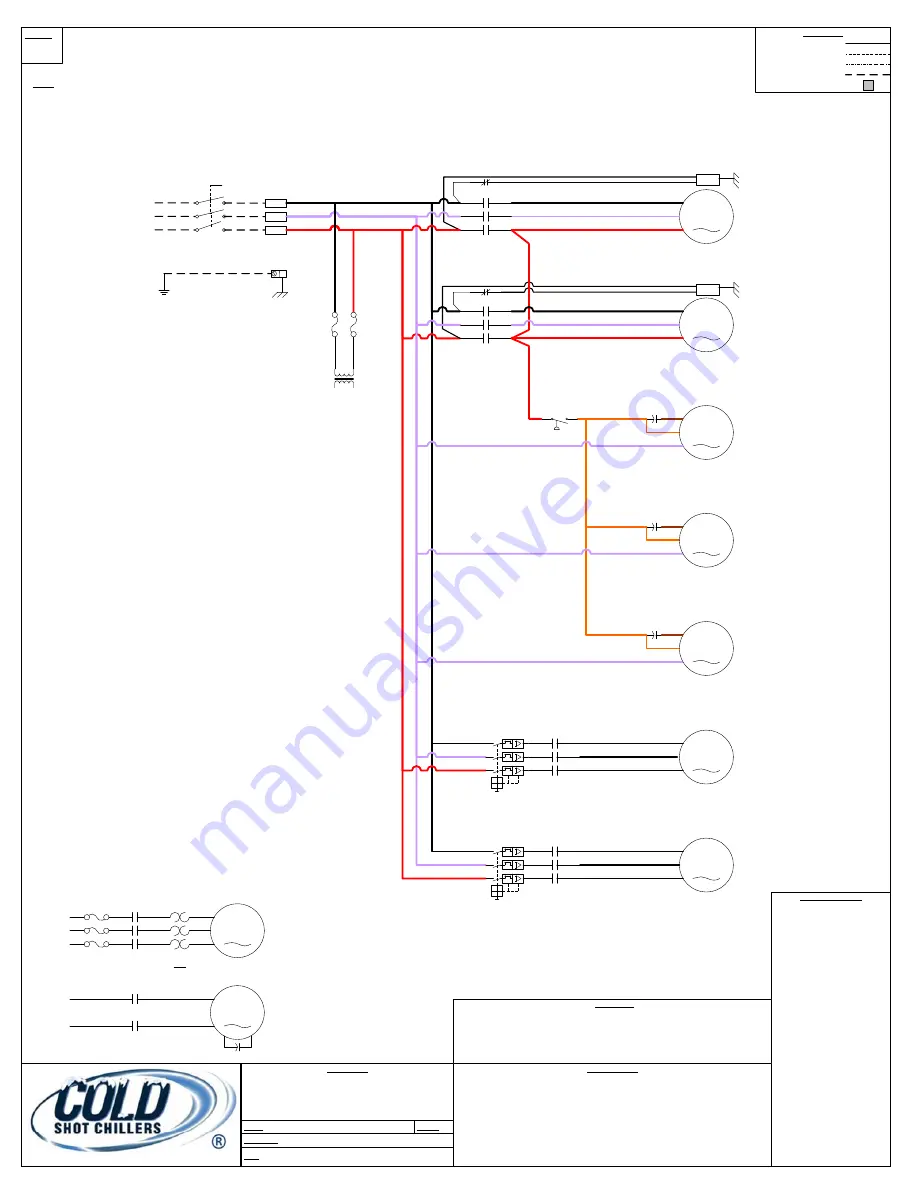

GENERAL NOTES

1. WARNING-For continued protection against fire hazard replace fuses with the same type and rating only.

2. Unit must be permanently grounded and conform to N.E.C. & local codes.

3. Use copper conductors for field-wiring. Class 1, unless noted. All wire based on 105°C insulation wire, minimum.

4. Wire colors shown may differ from actual unit.

5. Drawing line item reference identification:

- Number in parenthesis near output is location of controlled items.

- First number is sheet #, second & third are line#

- No underline indicates normally open (NO) contact

- Underline indicates normally closed (NC) contact

6. Design, specifications, and components are subject to change without notice.

7. All intellectual property, including designs and programming logic are the property of Cold Shot Chillers and is not

to be copied or used without permission from Cold Shot Chillers.

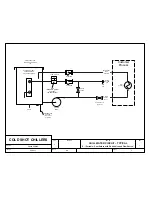

COMPONENT CODES

AUX

Auxiliary (contact block)

BZR

Buzzer

CC1

Compressor Contactor 1

CC2

Compressor Contactor 2

CCH

Crank Case Heater

COM

Common

CR

Control Relay

CR1

Control Relay for Cooling Mode Status

CR2

Control Relay for Active Cooling On

CR3

CR for Chiller Pump functions

CR4

CR for Process Pump functions

CR5

CR for Remote ON/OFF Operation

DB

Distribution Block

FPS

Fan-Cycling Pressure Switch

F1/F2

Fuse 1 and 2 (Transformer Primary)

F3

Fuse 3 (120VAC Control Voltage)

F4

Fuse 4 (24VAC Control Voltage)

FST

Flow Safety T-Stat

FZT

Freeze Safety T-Stat

GND

Ground

HG

Hot Gas

HPS

High Pressure Switch

L

Line

LAR

Low Ambient Relay

LAT

Low Ambient Thermostat

LFS

Liquid Flow Switch

LPS

Low Pressure Switch

LT1

Light 1 for Cooling Status – OK

LT2

Light 2 for Cooling Fault Condition

M

Motor

MS

Motor Starter

NC

Normally Closed

NO

Normally Open

PC1

Pump Contactor 1 (Chiller Pump)

PC2

Pump Contactor 2 (Process Pump)

PLC

Programmable Logic Controller

PS

Power Supply

RC

Run Capacitor

SW1

Selector Switch (Pump/Off/Cooling)

SW2

Selector Switch (Process Pump)

SW3

Local/Remote Switch

TB1

Terminal Block 1 (for Internal)

TB2

Terminal Block 2 (for External)

TC

Thermocouple

TLH

Tank Level Switch – High

TLL

Tank Level Switch – Low

TLM

Tank Level Switch – Mid

TRAN

Transformer

EDIT DATE:

August 26, 2015

DESCRIPTION

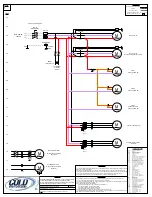

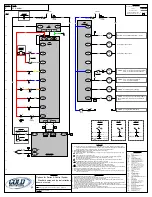

ELECTRICAL DRAWING: Series A – Level 1 Delta Controls

Typical design for One and Two Compressor systems.

Using standard 24VDC on/off inputs. 24VAC controls outputs.

Options and typical variations shown or noted.

FILE:

DWG_Electrical-DeltaControl-SeriesA120_081915.vsd

PAGE#:

1

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

SHEET:

1

PAGE:

A120-PowerCircuit(3phase)

LINE#

17

18

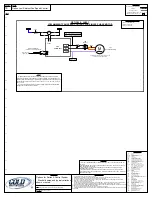

LINE LEGEND

FACTORY SUPPLIED/INSTALLED

DETAILS

FACTORY OPTION

FIELD SUPPLIED/INSTALLED

TERMINAL BLOCK CONTACT #

#

GROUNDING

LUG

CHASSIS

GND

GND

M

Pump #2 (Process Pump)

(OPTION)

PC2

M

Pump #1 (Chiller Pump)

PC1

M

Compressor #2

(Tandem Compressor Systems)

CC2

CCH

CC2-Aux

M

Compressor #1

CC1

CCH

CC1-Aux

MAIN POWER

3PHASE

L1

L2

L3

MAIN

DISCONNECT

L1

L2

L3

DB-Line

RC3

M

Fan #3

(180&240models)

(See Page Note #3)

RC2

M

Fan #2

(See Page Note #3)

FPS

RC1

M

Fan #1

(See Page Note #3)

MS1

( 212 )

MS2

( 207 )

Field Supplied/Installed

* PAGE NOTES

1. Control transformers must be wired/tapped for the appropriate incoming voltage. Depending on design, one dual

voltage or two independent voltages.

2. Models -24 to -90 models have 1 fan, -120 and -150 models have 2 fans. -180 and -240 models have 3 fans.

3. Fan speed controller will be installed on #2 fan on 120 to 150 models and installed on #3 on 180 and 240 models.

4. Fuse block, contactor, and overload may be used in place of motor starter and contactor combination.

5. Single phase pump motors may be used. Motors must be internally, thermally protected.

To CONTROL

CIRCUIT

( See 201 )

TRAN1

(PageNote 1,2)

F2

F1

M

Single Phase Pump Motor

(Example)

PC#

See PAGE NOTE #5

M

Three Phase Pump Motor

(Example)

PC#-OL

( ### )

PC#

FB

See PAGE NOTE #4

Содержание ACWC-180-EM-DR-LT-0-5

Страница 35: ...Notes...

Страница 36: ...MAINTENANCE RECORD DATE PROCEDURE PERFORMED...