CKL_StartupChecklist-2-20ton_0213.docx

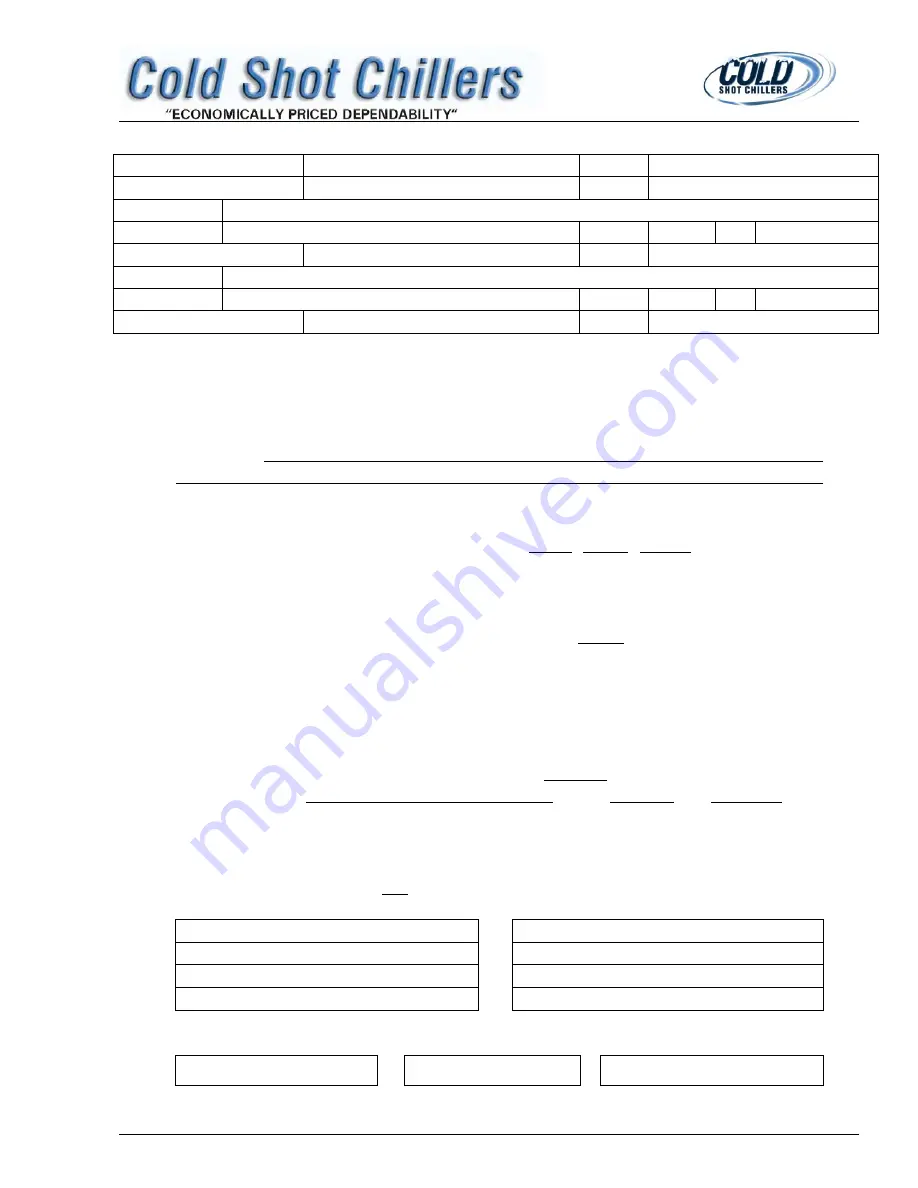

TYPICAL START-UP CHECK LIST

EQUIPMENT MODEL#

SERIAL#

OWNER NAME

PHONE#

ADDRESS

CITY

STATE

ZIP

INSTALLING CONTRACTOR

PHONE#

ADDRESS

CITY

STATE

ZIP

START-UP PERFORMED BY

PHONE#

* Designates Pre-Startup items. To be performed before Startup of system.

1.

*Manual referred to for details on installation and startup (IMPORTANT).

Yes No

2.

*Add additional information and notes on back of form, as needed.

Yes No

3.

*Is there any physical damage?

Yes No

a.

Will this prevent start-up?

Yes No

Description:

4.

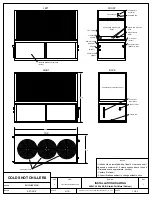

*Unit is installed level as per the installation instructions.

Yes No

5.

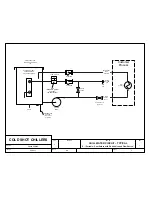

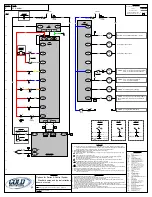

*Electrical circuit protection has been sized & installed properly.

Yes No

6.

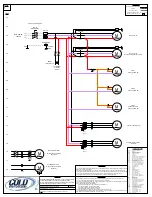

*Power supply agrees with the unit nameplate. V Ø Hz

Yes No

7.

*Electrical power wiring is installed properly.

Yes No

8.

*All terminals and plug assemblies are tight.

Yes No

9.

*Unit is grounded properly.

Yes No

10.

*Control voltage is appropriate per electrical drawing.

V

Yes No

11.

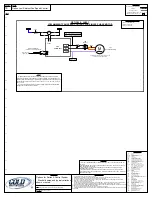

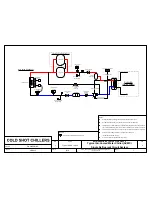

*All piping is connected properly, as appropriate.

Yes No

12.

*All chilled water valves are open, as appropriate.

Yes No

13.

*Crankcase heaters energized for 24 hours before start-up.

Yes No

14.

*Outdoor piping wrapped with electric heater tape, if necessary.

Yes No

15.

*Water loop volume greater than 6gal/ton.

Yes No

16.

*Proper fluid loop freeze protection provided to

˚F

a.

With type

mixture

% with

%

17.

Chilled water pump is operating with the correct rotation.

Yes No

18.

All air has been purged from the system.

Yes No

19.

Evaporator flow appropriate for capacity expected.(~3gpm/ton)

Yes No

20.

Check the pump(s) seals for any signs of leaking.

Yes No

21.

Measure the following under full load with clear refrigerant sight glass.

Yes No

Suction Pressure:

PSI

Ambient Temp:

˚F

Discharge Pressure:

PSI

Entering Fluid Temp:

˚F

Suction Line Temp:

˚F

Leaving Fluid Temp:

˚F

Superheat:

˚F

Set Value:

˚F

22.

Heat Exchanger models: If an extra heat exchanger is included with the chiller, ensure flow is

adjusted through the exchanger to achieve desired cooling:

Flowrate:

gpm Temp In:

˚F

Temp Out:

˚F

23.

Clean any strainers, as needed.

Yes No

24.

Operation Manual is given to customer.

Yes No

Содержание ACWC-180-EM-DR-LT-0-5

Страница 35: ...Notes...

Страница 36: ...MAINTENANCE RECORD DATE PROCEDURE PERFORMED...