34

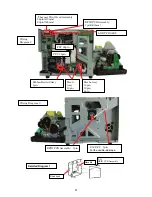

Replacement Procedure 6-10 GEAR_DUMPER

Disassembly mechanical Assy 2 screws.

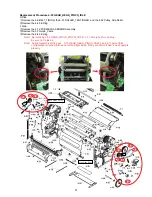

Replacement Procedure 6-11 GEAR_HEAD_PINCH_CAM_R

1-23 COVER_MECHA_R

E Ring 1 place.

Note) Be sure to lubricate gears and cams.

During assembly

5-15 GEAR_HEAD_PINCH_CAM_L and 6-11 GEAR_HEAD_PINCH_CAM_R

CAM-configuration must be matched on left and right sides. If they are not matched, it won't

operate properly.

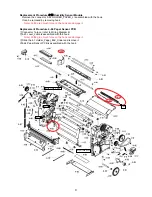

Replacement Procedure 6-30 STEP_MOTOR_MAIN_LC

1-4 CASE_FRONT

1-2 CASE_SIDE_R

1-22 COVER_MECHA_L

1-23 COVER_MECHA_R

4-68 Auto Cutter Unit

4-9 BELT_TIMING

4-22 Pulley, Grip Roller

4-53 GEAR_HEAD_PINCH_IDLE

4-55 GEAR_ROLL_REDUCTION_3

Please remove parts respectively.

4-60 Wiring Harness 6pin

(

refer to Wiring Diagram 5

)

6-18 HOLDER_CABCLE_B

Remove the 6-4 STAY_MAIN_MOTOR the screw from 3 places.

Note) Be careful not to drop or lose the 6-7 Damper_Motor and the 6-27 Spcer_Motor_Damper

Remove the connector, and remove the screws from 2 places

Note) Check the warnings for all parts.

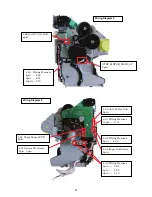

Replacement Procedure 6-12 Bearing(d6-D12)

1-23 COVER_MECHA_R

4-9 BELT_TIMING

4-22 Pulley, Grip Roller

4-7 SPRING_PINCH

Remove the 6-1 PLATE_PINCH_UP_

R

the E Ring from 2 place

E Ring 1 place.

Replacement Procedure 6-13 Holder_Ribbon_RFID

1-23 COVER_MECHA_R

2 screws

(

Screw torque 0.60

±

0.5N

・m)

Replacement Procedure 6-29 Holder_Ribbon_Supply_R

1-23 COVER_MECHA_R

3-22 screws 2 place