SERVICE MANUAL

Transmig 165

ST

Transmig 165

ST

SERVICE MANUAL

Transmig 165

ST

Transmig 165

ST

MIG (GMAW) WELDING 5-8 Manual 0-5442

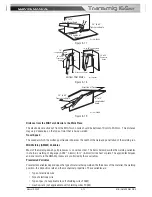

5.08 Wire Reel Brake

The wire reel hub incorporates a friction brake which is adjusted during manufacture for optimum breaking.

If it is considered necessary, adjustment can be made by turning the large nut inside the open end of the

hub clockwise to tighten the brake. Correct adjustment will result in the wire reel circumference continuing

no further than 10-20mm after release of the trigger. The electrode wire should be slack without becoming

dislodged from wire spool.

CAUTION

Overtension of brake will cause rapid wear of mechanical WIREFEED parts, overheating of electrical

componentry and possibly an increased incidence of electrode wire Burnback into contact tip.

Wire Reel Brake Adjustment Nut

Art # A-12909

Figure 5-10: Wire Reel Brake

5.09 Setup for MIG (GMAW) Welding with Gas Shielded Mig Wire

A. Fit the MIG Torch to the Power Source. (Refer to section 5.02 Attaching the Tweco Fusion MIG Torch).

B. Connect the Mig torch polarity lead to the positive welding terminal (+). If in doubt, consult the electrode

wire manufacturer. Welding current flows from the Power Source via Dinse terminals. It is essential,

however, that the male plug is inserted and turned securely to achieve a sound electrical connection.

C. Switch the Power Source On/Off switch located on the rear of the Power Source to the On position and

ensure the Power indicator on the Front Panel is illuminated. Set the MIG Torch trigger switch operation

either 2T or 4T mode. Refer to section 4.02.10.

D. Select MIG mode with the process selection control. (refer to Section 4.02.11 for further information).

E. Fit the correct Feed Roll for the Gas Shielded MIG wire being used. Refer to section 2.11 Options and

Accessories for Feed Roll types and Part Numbers

F. Place the MIG wire spool onto the spool holder. Refer to sections 5.03 for 100mm diameter spools or 5.04

for 200mm diameter spools.

G. Feed wire through the wire drive mechanism. Refer to section 5.05.

H. Feed the wire through the MIG torch by depressing the MIG torch triggered. DO NOT let the wire touch

any conductive material or your skin as the wire is electrical HOT when the torch triggered is depressed.

- Secondary voltage and the feed rollers run at constant run-in speed for about 3 seconds.

- After the 3 seconds, the secondary voltage is still present but the feed rollers run the wire speed you set

on the Wirespeed control.

- After a further 20 seconds, the feed rollers stop and the secondary voltage turns off. This is built into the

design for safety reasons.

Содержание Transmig 165ST

Страница 16: ...SERVICE MANUAL Transmig 165ST Transmig 165ST GENERAL INFORMATION 1 10 Manual 0 5442 Notes ...

Страница 32: ...OPERATION 4 6 Manual 0 5442 SERVICE MANUAL Transmig 165ST Transmig 165ST Notes ...

Страница 84: ...SERVICE MANUAL Transmig 165ST Transmig 165ST THEORY OF OPERATION 9 2 Manual 0 5442 Notes ...

Страница 115: ...SERVICE MANUAL Transmig 165ST Transmig 165ST Manual 0 5442 12 3 ASSEMBLY PROCEDURE 8 7 A 10011 9 A 10012 ...

Страница 118: ...SERVICE MANUAL Transmig 165ST Transmig 165ST ASSEMBLY PROCEDURE 12 6 Manual 0 5442 14 Art A 13011 ...

Страница 120: ...SERVICE MANUAL Transmig 165ST Transmig 165ST ASSEMBLY PROCEDURE 12 8 Manual 0 5442 Notes ...

Страница 125: ...SERVICE MANUAL Transmig 165ST Transmig 165ST This Page Intentionally Blank ...