5 - SETTING UP CONNECT TOUCH CONTROL

5.1 General description

Connect Touch includes the 4.3 in. touch screen allowing for

easy system control. Navigation through the Connect Touch

control is either using the touch screen interface or by connecting

to the web interface.

The navigation menus are the same for both connection

methods (Connect Touch user interface and web browser). It is

recommended to use a pen for the navigation via the touch screen.

NOTE: Some functions are unavailable when using the

web browser interface.

The Connect Touch interface includes the following screens:

• Welcome screen

•

Synoptic screen

• Operating mode selection screen

•

Data/configuration screens

•

Password entry and language selection screen

• Alarms screen

•

Parameter modification screen

• Time schedule screen

5.2 Welcome screen

The Welcome screen is the first screen shown after starting the

user interface. It displays the application name as well as the

current software version number.

•

To exit the Welcome screen and go to the Home screen

(see section

), press the

Home

button.

1. Home button

2. Software version number

3. Information message box

Information message box:

The information displayed

in the status bar at the bottom of the screen includes relevant

messages regarding the current user action.

MESSAGE

STATUS

COMMUNICATION

FAILURE!

Equipment controller did not respond while

reading the table content.

ACCESS DENIED!

Equipment controller denies access to one of

the tables.

LIMIT EXCEEDED! The value entered exceeds the parameter limit.

Save changes?

Modifications have been made. The exit must

be confirmed by pressing Save or Cancel.

HIGHER FORCE

IN EFFECT!

Equipment controller rejects Force or Auto

command.

Too many users

connected ! Please

try again later ...

Too many users connected at the same time

(WEB INTERFACE ONLY)

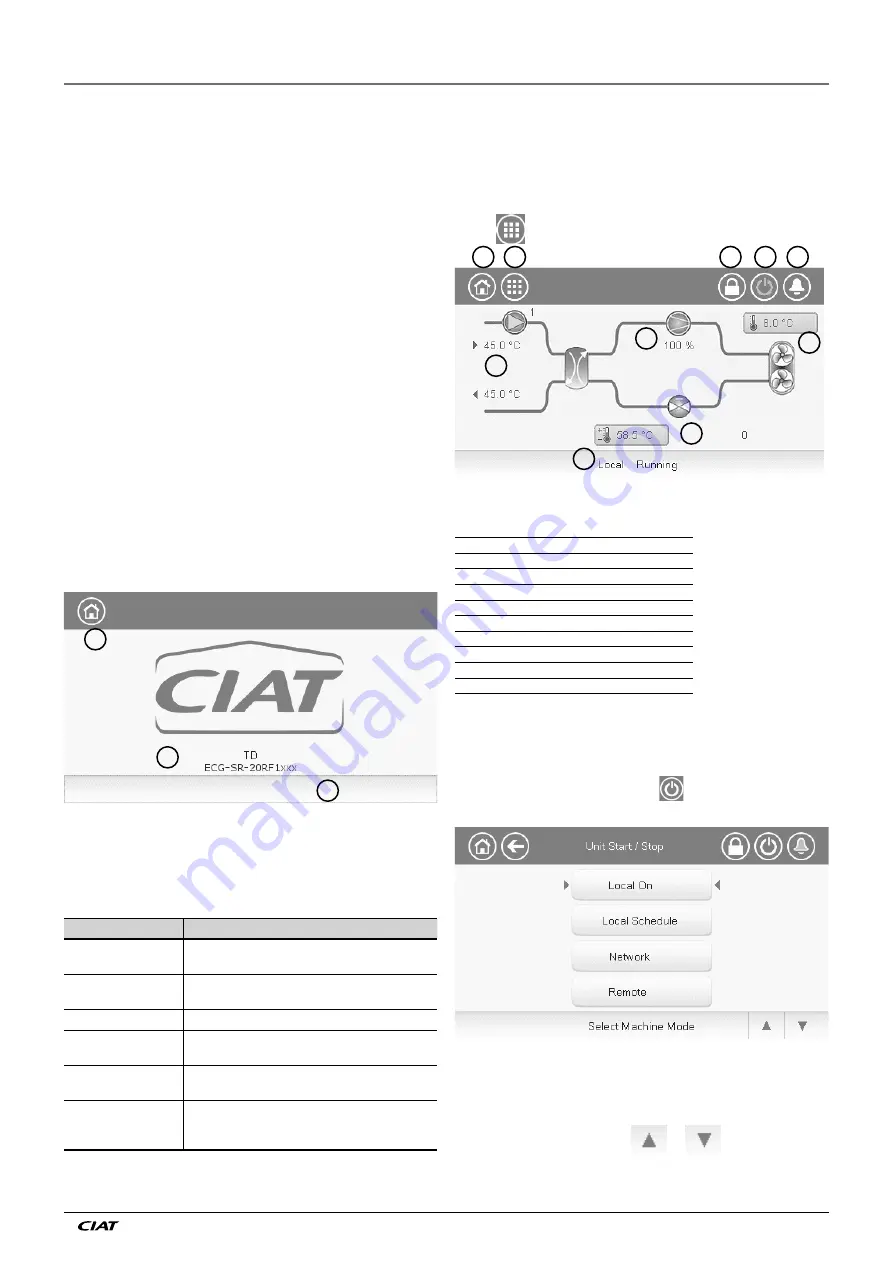

5.3 Synoptic screen

The Synoptic screen allows you to monitor the vapour-refrigeration

cycle. The diagram indicates the current status of the unit, giving

information on the unit capacity, the status of water heat exchanger

pumps, and the pre-defined setpoint parameter.

All unit functions can be accessed by pressing the

Main menu

button

Example: Synoptic view. This picture is for information only. It may differ from the

actual look, depending on pumps and OAT sensor availability.

1. Home button

2. Main menu button

3. LWT and EWT (condenser)

4. Comp unit capacity

5. Login button (restricted access to menus)

6. Start/Stop button

7. Alarm button

8. Outdoor air temperature

9. Setpoint

10. Unit running status

5.4 Unit start/stop

With the unit in the Local off mode:

To display the list of operating modes and select the required

mode, press the

Start/Stop

button

in the upper-right corner

of the Synoptic screen.

IMPORTANT: When entering the menu, please note that

the currently selected item corresponds to the last

running operating mode.

Press the Navigation button (

or

) to go to the next

page.

1

2

3

5

9

4

10

8

7

6

1

2

3

EN - 7

AQUACIAT

CALEO