4 - HOW TO USE CONNECT TOUCH CONTROL

4.1 User interface

Connect Touch is a 4.3” colour touch screen with quick display

of alarms, current unit operating status, etc. It allows for web

connectivity and custom language support (control parameters

displayed in the language selected by the user).

Connect Touch: Welcome screen for AQUACIAT

CALEO

If the touch screen is not used for a long period of time,

the Welcome screen is displayed, and then it goes blank.

The control is always active and the operating mode

remains unchanged. Press anywhere on the screen and

the Welcome screen will be displayed.

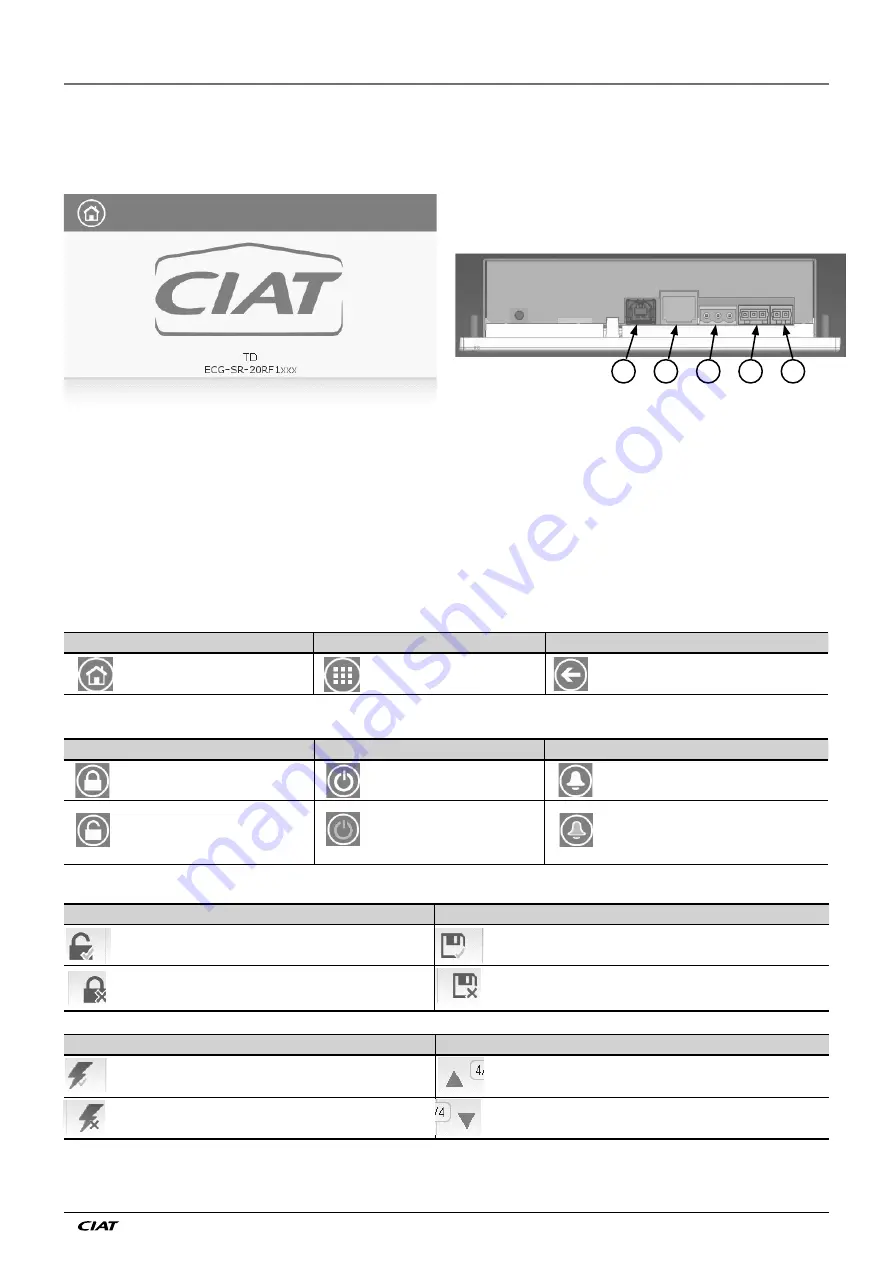

4.2 Connections

Connections are located on the bottom side of the controller.

The controller comes with two RS485 ports, where the first port

is used to connect to Modbus and the second RS485 port is

used for internal communication. The Ethernet port allows for

TCP/IP communication or BMS (Building Management System)

connection thanks to BACnet/IP communication.

1

2

3

4

5

Legend:

1. USB connector

2. Ethernet connector

3. Modbus (RS485) connector *

4. Internal bus (RS485)

5. Power supply connector (24 VAC)

* This RS-485 bus can be used as a second internal bus for

the connection of gateway. If it is the case, then Modbus RTU

will NOT be available on this port.

4.3 Connect Touch buttons

HOME SCREEN

Home button

Main Menu button

Back button

Home screen displayed

Main Menu displayed

Go back to the previous screen

Login button

Start/Stop button

Alarm button

Basic access

Unit is stopped (white icon)

No alarm active on the unit

User access

Unit is running (green icon)

Blinking icon:

Partial alarm (one

compressor affected by the existing alarm)

or Alert (no action taken on the unit)

Steady icon:

Alarm(s) active on the unit

OTHER SCREENS

Login screen

Parameters screen(s)

Login: Confirm advanced access login

Save changes

Logout: Reset the user level access and go to the splash

screen

Cancel your modifications

Force screen (override)

Navigation buttons

Set force: Override the current command (if possible)

Displayed when the menu includes more than one page:

Go to the previous page

Remove force: Remove the forced command

Displayed when the menu includes more than one page:

Go to the next page

EN - 5

AQUACIAT

CALEO