Rev

F

Doc

01-20099

30

of

42

D. MAINTENANCE

WARNING

To avoid injury, always turn off the unit power switch before working on gate.

Regularly performance of preventive maintenance is essential for reliable system

operation because it corrects small problems before they turn into emergencies.

LiftMaster recommends performing preventive maintenance every 6 to 12 months,

depending upon the amount of gate usage.

•

If the gate is installed in a private residence or small apartment house where

usage is not severe, yearly preventive maintenance is acceptable.

•

If the gate is installed in a high-traffic application, semi-annual preventive

maintenance is essential.

PREVENTIVE MAINTENANCE TASKS

1.

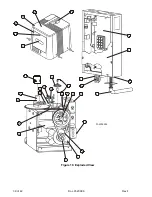

Gate Arm:

Check for wear in the moving parts. Check for hardware tightness.

2.

Gate:

must swing freely without any impediment. Check hinges, grease if

necessary.

3.

Chain:

Check for wear and tension. If loose, adjust tension with chain tensioner.

Do not oil chain.

4.

Sprocket:

must not be loose in the shaft. Tighten set screws if loose

➊

.

5.

Limit switches:

contacts must bounce back rapidly when they are pressed and

released.

6.

Belt:

Check for wear and tension (25 to 30 lb.). Adjust the AC motor up or down

to set proper tension.

7.

Pulleys:

must all line up and be firmly secured to their shafts. Tighten set

screws if loose

➊

.

8.

Gear Box:

Check for no oil leakage around the bushings. Do not oil gearbox.

9.

Control board:

Check for water damage or burned spots. All connectors

secured to the board.

10.

Wiring:

Check all wiring for any insulation damage. Check for loose wire

connections.

11.

No Rust:

Check for rust throughout the unit. Check corners for water

entrapment.

12.

Fire Open:

Activate Fire department switch to verify emergency gate opening.

13.

Gate Sense:

Check for the gate sensitivity (refer to Part 2, System Installation,

paragraph J, Gate Sensitivity Adjustments).

14.

Photo-Sensors:

Ensure that sensor emitters/receivers are aligned and clean.

Verify that inputs stop gate.

15.

Obstruction Alarm:

Check for proper operation. Alarm must sound after two

consecutive gate obstruction faults.

NOTES:

➊

: To prevent loosening, two set screws are used in each hole and Loctite

threadlocker 242 is applied.