15

F.200/TITAN 200/MAR 97

15. Close the front guard and press CLEAR. This will

raise the knife and clamp to the up position.

16. Turn the power off and disconnect the machine

power cord.

17. Tighten all knife bolts securely.

18. Plug in the power cord and turn the power on.

Make a test cut through a full lift of paper and make

minor adjustments if necessary by repeating steps 9

through 17. NOTE: If the knife ends cut but the middle

doesn’t, you could have dips or uneven spots in the

knife and/or cutting stick. These can be eliminated by

placing 1/2” strips of paper in the table slot beneath

the cutting stick to shim it.

19. Send the dull knife to a knife grinder. Do not attempt

to sharpen your own knives! See the Knife Tips section

(pg. 23) to determine the knife bevel angle.

False Clamp Plate (Optional)

To prevent marking on pressure sensitive jobs, a false

clamp plate is available as an optional item for your

machine. This plate attaches to the bottom of the

clamp. It is secured with wing nuts on studs that pass

through the top of the clamp.

To install:

1. Make sure the knife and clamp are in the up position.

If they are not, turn on the power using the red and

yellow main power switch, close the front guard, and

press the CLEAR button. This will preset the

backgauge and send the knife and clamp up.

2. Turn the power off and disconnect the power cord.

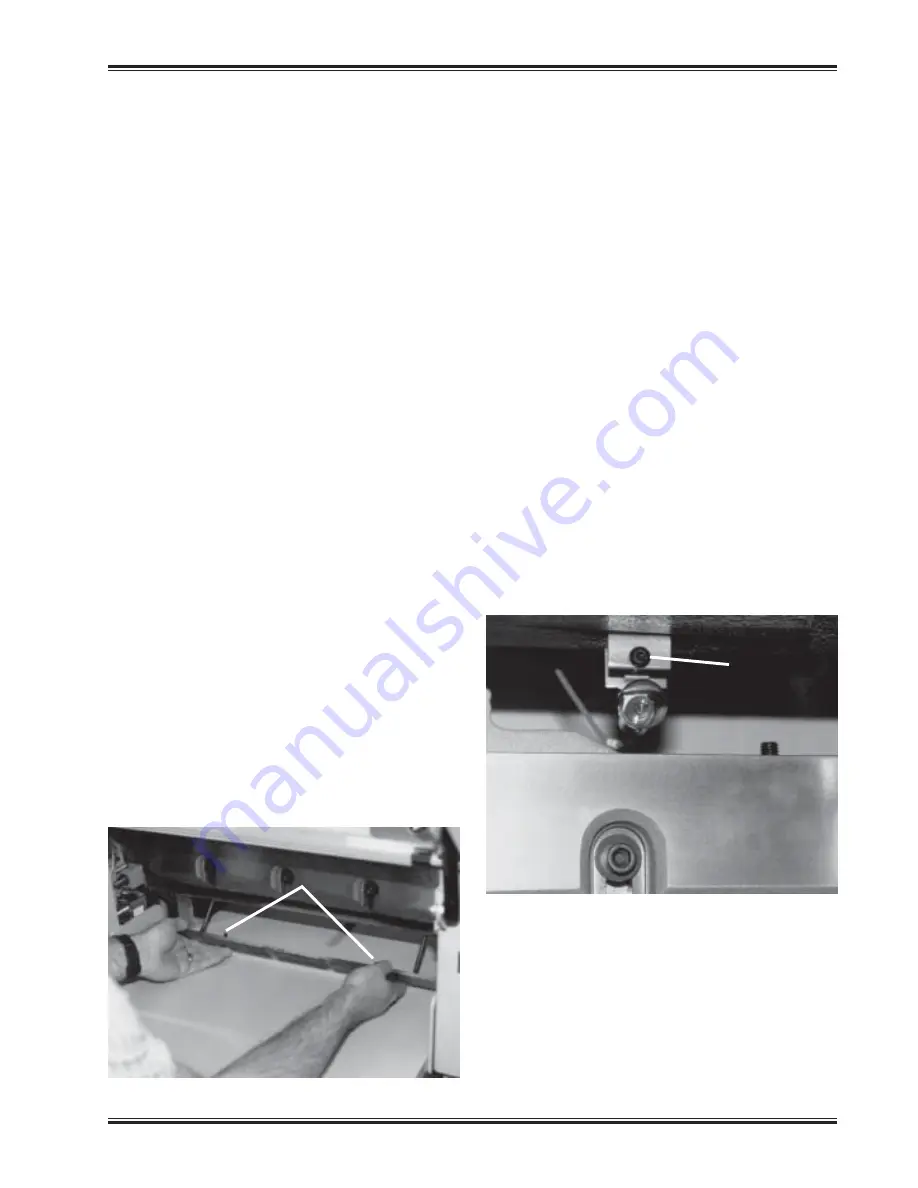

3. Open the front guard and slide the false clamp plate

under the knife and clamp (fig. 17), and slide the plate

up into position with the locator pins toward the front of

the machine. The locator pins insert into holes in the

bottom front of the clamp.

4. Hold the plate in position and secure with the wing

nuts provided.

5. Change the false clamp setting of the machine to

ON to prevent the backgauge from crashing into

the false clamp plate. This is done in the Maintenance

Mode/Parameters/False Clamp screen. For more

details on how to do this, see the Operating Controls/

Maintenance Mode/Parameters section (pg. 20).

NOTE: The minimum cut with the false clamp plate

attached is 1-3/4”

Line Light

The Titan 200 is equipped with two lights which provide

a line of light on the paper in the approximate location

of where the paper will be cut. The lights come on when

power to the machine is turned on. The light from each

bulb reaches the table after passing between the knife

and clamp. Each light is focused with a socket head

capscrew (fig. 18).

To Adjust:

1. Place a wide sheet of paper on the cut stick to view

the line light.

2. Using a 3/16” hex allen wrench, turn one of the cap

screws until you see a 1/16-1/8” beam. Note: it is best

to start by turning the screw clockwise. If the screw

turns all the way in before a line appears, begin turning

the screw counterclockwise.

3. Similarly, turn the adjustment screw of the other

(fig. 18)

Line Light

Adjustment

Screw

(fig. 17)

Locator Pins

NOTICE: UNSUPPORTED PRODUCT!

NO TECHNICAL SUPPORT AVAILABLE!

NO REPAIR PARTS AVAILABLE!