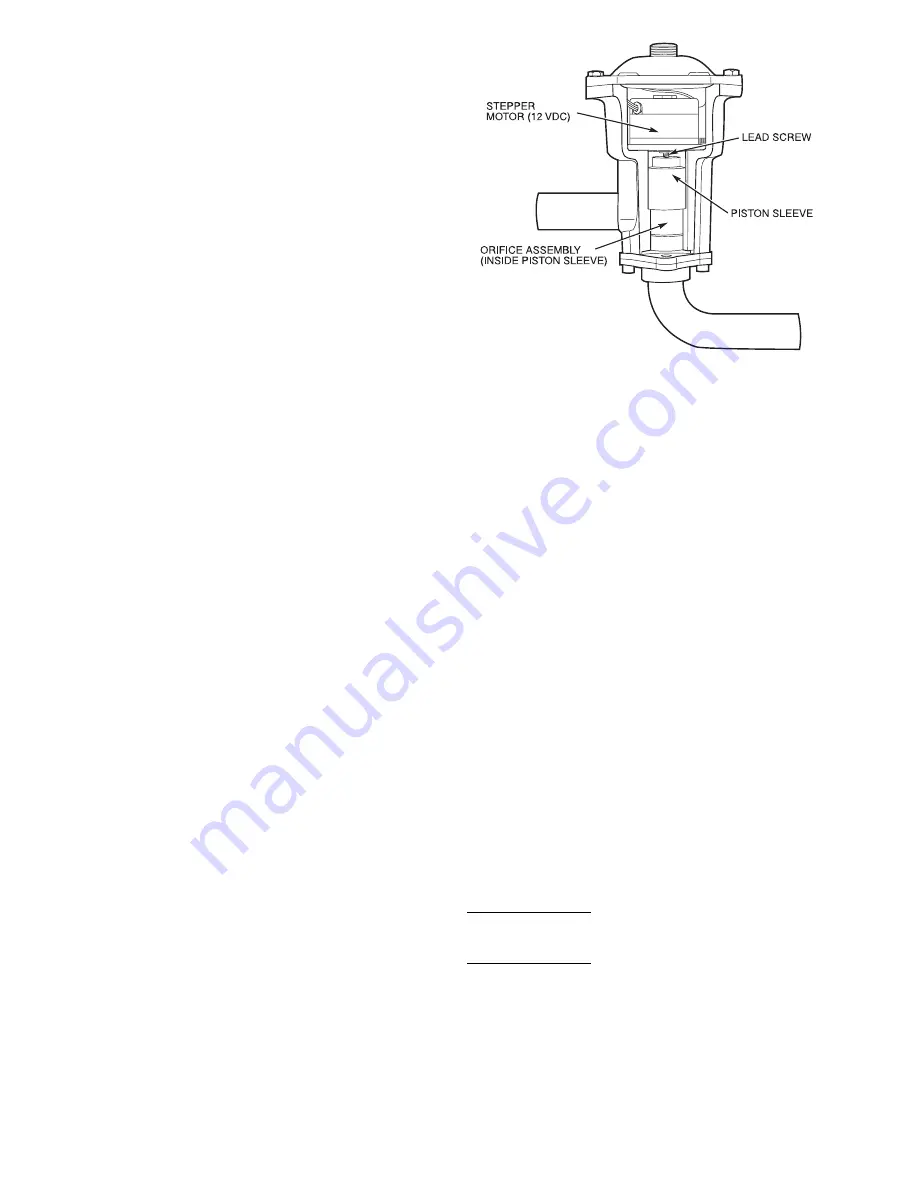

Electronic Expansion Valve (EXV) (See Fig. 14)

—

Standard units are equipped with a bottom seal EXV. This

device eliminates the use of the liquid line solenoid pump-

down at unit shutdown. An O-ring has been added to bottom

of orifice assembly to complete a seal in the valve on shut-

down. This is not a mechanical shut-off. When service is re-

quired, use the liquid line service valve to pump down the

system.

High pressure refrigerant enters bottom of valve where it

passes through a group of machined slots in side of orifice

assembly. As refrigerant passes through the orifice, it drops

in pressure. To control flow of refrigerant, the sleeve slides

up and down along orifice assembly, modulating the size of

orifice. The sleeve is moved by a linear stepper motor that

moves in increments controlled directly by the processor. As

stepper motor rotates, the motion is translated into linear move-

ment of lead screw. There are 1500 discrete steps with this

combination. The valve orifice begins to be exposed at

320 steps. Since there is not a tight seal with the orifice and

the sleeve, the minimum position for operation is 120 steps.

Two thermistors are used to determine suction superheat.

One thermistor is located in the cooler and the other is lo-

cated in the cylinder end of the compressor after refrigerant

has passed over the motor. The difference between the

2 thermistors is the suction superheat. These machines are

set up to provide approximately 5 to 7 F (2.8 to 3.9 C) super-

heat leaving the cooler. Motor cooling accounts for approxi-

mately 22 F (12.2 C), resulting in a superheat entering com-

pressor cylinders of approximately 30 F (16.7 C). This increases

performance of cooler by reducing the amount of superheat

needed.

Because the valves are controlled by the EXV module, it

is possible to track the position of the valve. Valve position

can be used to control head pressure and system refrigerant

charge.

During initial start-up, the EXV module will drive each

valve fully closed. After initialization period, valve position

is controlled by the EXV module and the MBB.

The EXV is used to limit the maximum cooler saturated

suction temperature to 55 F (12.8 C). This makes it possible

for the chiller to start at high cooler fluid temperatures with-

out overloading the compressor.

Energy Management Module (Fig. 15) —

This

factory-installed option or field-installed accessory is used

for the following types of temperature reset, demand limit,

and/or ice features:

• 4 to 20 mA leaving fluid temperature reset (requires field-

supplied 4 to 20 mA generator)

• 4 to 20 mA cooling set point reset (requires field-supplied

4 to 20 mA generator)

• Discrete inputs for 2-step demand limit (requires field-

supplied dry contacts capable of handling a 5 vdc, 1 to

20 mA load)

• 4 to 20 mA demand limit (requires field-supplied 4 to 20

mA generator)

• Discrete input for Ice Done switch (requires field-supplied

dry contacts capable of handling a 5 vdc, 1 to 20 mA load)

See Demand Limit and Temperature Reset sections on

pages 43 and 45 for further details.

Capacity Control —

The control system cycles com-

pressors, unloaders, and hot gas bypass solenoids to main-

tain the user-configured leaving chilled fluid temperature set

point. Entering fluid temperature is used by the Main Base

Board (MBB) to determine the temperature drop across the

cooler and is used in determining the optimum time to add

or subtract capacity stages. The chilled fluid temperature set

point can be automatically reset by the return temperature

reset or space and outdoor-air temperature reset features. It

can also be reset from an external 4 to 20 mA signal (re-

quires Energy Management Module FIOP/accessory).

With the automatic lead-lag feature in the unit, the control

determines randomly which circuit will start first, A or B. At

the first call for cooling, the lead compressor crankcase heater

will be deenergized, a condenser fan will start, and the com-

pressor will start unloaded.

NOTE: The automatic lead-lag feature is only operative when

an even number of unloaders is present. The 040-070 units

require an accessory unloader for the lead-lag feature to be

in effect.

If the circuit has been off for 15 minutes, and the unit is

a TXV unit, liquid line solenoid will remain closed during

start-up of each circuit for 15 seconds while the cooler and

suction lines are purged of any liquid refrigerant. For units

with EXVs, the lead compressor will be signaled to start.

The EXV will remain at minimum position for 10 seconds

before it is allowed to modulate.

After the purge period, the EXV will begin to meter the

refrigerant, or the liquid line solenoid will open allowing the

TXV to meter the refrigerant to the cooler. If the off-time is

less than 15 minutes, the EXV will be opened as soon as the

compressor starts.

The EXVs will open gradually to provide a controlled start-up

to prevent liquid flood-back to the compressor. During start-

up, the oil pressure switch is bypassed for 2 minutes to al-

low for the transient changes during start-up. As additional

stages of compression are required, the processor control will

add them. See Tables 5A and 5B.

If a circuit is to be stopped, the control will first start to

close the EXV or close the liquid line solenoid valve.

For units with TXVs, the lag compressor(s) will be shut down

and the lead compressor will continue to operate for 10 sec-

onds to purge the cooler of any refrigerant.

For units with EXVs, the lag compressor(s) will be shut down

and the lead compressor will continue to run. After the lag

compressor(s) has shut down, the EXV is signaled to close.

The lead compressor will remain on for 10 seconds after the

EXV is closed.

During both algorithms (TXV and EXV), all diagnostic

conditions will be honored. If a safety trip or alarm condi-

tion is detected before pumpdown is complete, the circuit

will be shut down.

Fig. 14 — Electronic Expansion Valve (EXV)

16

Содержание 30GTN

Страница 6: ...Fig 1 Typical Control Box 080 110 and Associated Modular Units Shown 6 ...

Страница 7: ...Fig 2 24 V Control Schematic Unit Sizes 040 070 7 ...

Страница 8: ...Fig 3 24 V Control Schematic Unit Sizes 080 110 230B 315B 8 ...

Страница 9: ...Fig 4 24 V Control Schematic Unit Sizes 130 210 230A 315A 330A B 420A B 9 ...

Страница 75: ......