62-10848

5-10

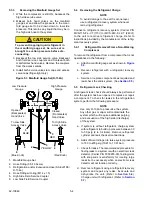

5.16 Diagnostic Tool

NOTE

The Cab Command diagnostic tool comes

with two jumpers. These are not applicable

to the 30S system and should not be used in

this application.

Figure 5.10 Cab Command Diagnostic Tool

(CTD P/N 07-00440-00)

a. Testing a cab command cable that is already

installed on the unit and routed into the truck

cab requires the use of both pieces of the diag-

nostic tool.

b. Unplug the cab command cable from the micro-

processor and also from the back of the cab

command module.

c. Plug one end of the cable into the primary tool

and the other end into the remote tool.

d. Begin the test by turning on the power switch

and observing the sequence of green lights. As

each circuit is tested, the corresponding light is

illuminated. If a fault is found in the cable, the

light that corresponds to that particular circuit is

not illuminated.

e. To test a cable that is not installed on a unit, sim-

ply plug each end of the cable into the primary

tool and perform the test as above.

5.17 Microprocessor

CAUTION

!

Under no circumstances should anyone

attempt to repair the microprocessor

module or Cab Command! Should a prob-

lem develop with these components, con-

tact your nearest Carrier Transicold

dealer for replacement.

Although there is less danger of electrical static dis-

charge (ESD) damage in the outdoor environment,

where the processor is likely to be handled, proper

board handling techniques should be stressed. Boards

should always be handled by their edges, in much the

same way one would handle a photograph. This not

only precludes the possibility of ESD damage, but also

lowers the possibility of physical damage to the elec-

tronic components. Although the microprocessor

boards are fairly rugged when assembled, they are

more fragile when separated and should always be

handled carefully.

When welding is required on the unit frame, or on the

front area of the truck, ALL wiring to the microprocessor

MUST be disconnected. When welding is performed on

other areas of the truck and van, the welder ground con-

nection MUST be in close proximity to the area being

welded. It is also a good practice to remove both battery

cables before welding on either the unit frame or the

truck to prevent possible damage to other components

such as the alternator and voltage regulator.

5.18 Evaporator Coil Cleaning

The use of recycled cardboard cartons is increasing. The

recycled cardboard cartons create much more fiber dust

during transport than “new” cartons. The fiber dust and

particles are drawn into the evaporator where they lodge

between the evaporator fins. If the coil is not cleaned on

a regular basis, sometimes as often as after each trip,

the accumulation can be great enough to restrict air flow,

cause coil icing, repetitive defrosts and loss of unit

capacity. Due to the ”washing” action of normal defrost

the fiber dust and particles may not be visible on the face

of the coil but may accumulate deep within.

It is recommended to clean the evaporator coil on a reg-

ular basis, not only to remove cardboard dust, but to

remove any grease oil film which sometimes coats the

fins and prevents water from draining into the drain pan.

Cardboard fiber particles after being wetted and dried

several times can be very hard to remove. Therefore,

several washings may be necessary.

a. Spray coil with a mild detergent solution such as

any good commercial-grade automatic dish

washer detergent and let the solution stand for a

few minutes. Reverse flush (opposite normal air

flow) with clean water at mild pressure. A gar-

den hose with spray nozzle is usually sufficient.

Make sure drain lines are clean.

b. Run unit until defrost mode is initiated to check

for proper draining from drain pan.

5.19 Condenser Coil Cleaning

Remove all foreign material from the condenser coil by

reversing the normal air flow. (Air is pulled in through

the front.) Compressed air or water may be used as a

cleaning agent. It may be necessary to use warm water

mixed with any good commercial dishwasher deter-

gent. Rinse coil with fresh water if a detergent is used.

P

rimary

Tool

Remote

Tool

Содержание INTEGRA 30S

Страница 2: ......

Страница 4: ......

Страница 8: ......

Страница 14: ...62 11868 1 8 ...

Страница 18: ......

Страница 32: ......

Страница 40: ......

Страница 60: ......

Страница 62: ......

Страница 64: ......

Страница 65: ...62 10848 Figure 7 2 Electrical Schematic Wiring Diagram Based On Dwg No 62 61350 Rev E ROAD ONLY ...

Страница 66: ......

Страница 69: ......