8200-M554-O1 Rev C 2XX-EIP Installation and Setup Manual

2

INSTALLATION

Mounting the 2XX-EIP Option Card

NOTE:

Should your indicator come with the 2XX-EIP option card already installed, the

following section describing mounting does not apply. Proceed to the

Node Address Setup

section.

CAUTION!

This board contains static sensitive components. Improper

handling can result in damage to or destruction of the components or board.

Such actual and/or consequential damage IS NOT covered under warranty.

1.

Make sure the power to the indicator is OFF. Unplug the AC power cord.

2.

Loosen the gland connectors where the AC power cord and any other cables enter the

indicator.

3.

Remove the rear panel on the indicator.

On the 205/210, remove the 12 acorn nuts securing the rear panel to the front housing.

On the 225, remove the 14 acorn nuts securing the rear panel to the front housing.

4.

Separate the rear panel from the front housing on the indicator.

5.

Lift the panel from the main housing, taking care not to stretch the cable and wires between

the panel and main housing. Lay the panel on the workbench next to the indicator.

6.

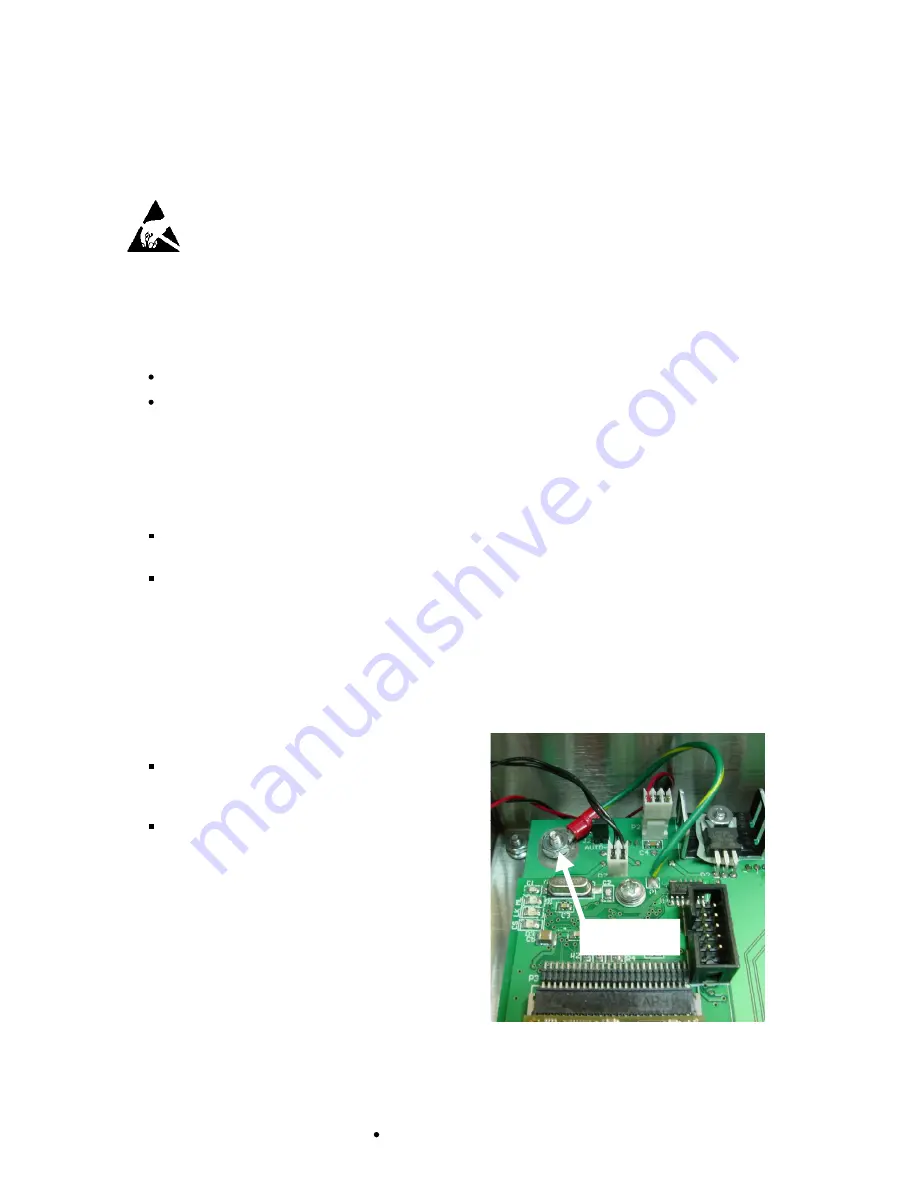

Referring to the illustrations on page 3, locate the threaded stand-off and the OPTION

BOARD connector on the indicator mainboard.

205/210 – The threaded stand-off is below P3 and the OPTION BOARD connector

is P10.

225 – The threaded stand-off is near P9 and the OPTION BOARD connector is P15.

7.

To install the option 2XX-EIP card, carefully align the connector P4 (pins on the bottom side

of the 2XX-EIP board) with connector P10 on the 205/210 or P15 on the 225 mainboard

and then apply even downward pressure to the end of the 2XX-EIP board (with P4 pins on

the bottom side).

8.

Align the hole in the 2XX-EIP board with the threaded stand-off on the indicator main board

and using the lock washer and screw supplied with the 2XX-EIP board, secure the 2XX-EIP

to the indicator mainboard.

9.

To attach the ground wire:

On the 205/210, remove a 6-32 nut and

washer from the threaded stud at the corner

of the indicator mainboard.

On the 225, remove a 6-32 nut and washer

from the threaded stud at the center of the

indicator mainboard.

10.

Connect the ground wire from the option card by

placing the ring terminal over the 6-32 threaded

stud.

11.

Reinstall the washer and 6-32 nut and tighten.

NOTE:

The ground wire attachment example

shown is on the 205/210 mainboard. The

attachment for the 225 is similar.

Attach

Ground Here