37

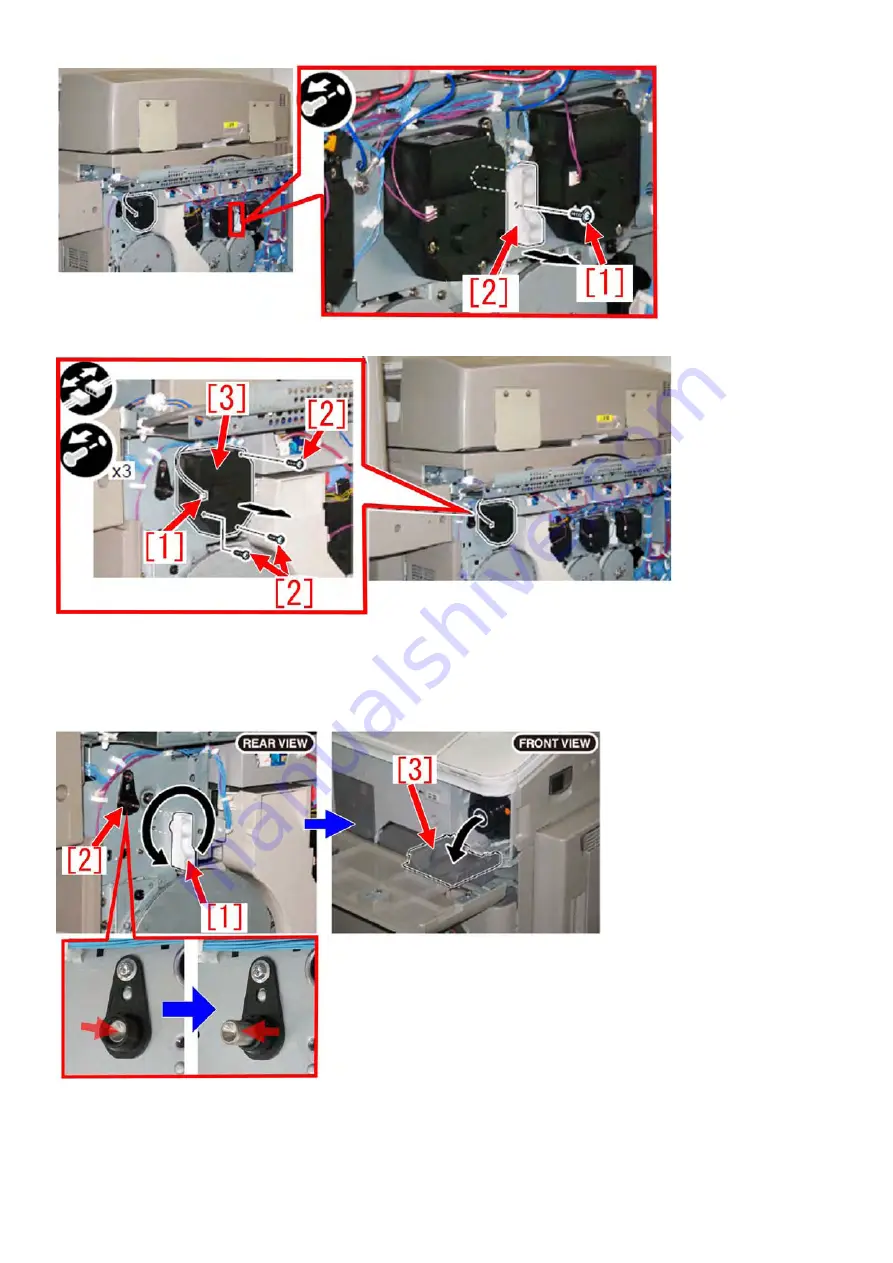

a-2) Remove the connector [1] and the 3 screws [2]. Detach the toner container drive motor [3].

a-3) Turn the tool [1] in the direction of the arrow. Check a sound the bottle is detached (Turn the tool until a

clicking sound is heard.)

[Reference] After the shaft [2] retreats and comes up again, the toner bottle is detached, and then the small

door [3] opens.

a-4) When all the toner bottles have been detached, remove the hopper unit. If the release holder shift cam

HP sensor is badly soiled, replace the release holder shift cam HP sensor. Refer to step "b) Removing the

Содержание imageRUNNER ADVANCE C5000 Series

Страница 1: ...im C mageRU Canon U UNNER U S A In T ADVAN nc ech W NCE C9 hni Wo 9000 Ser cal Work ries l kboo ok ...

Страница 3: ...1 Symptoms Solutions For the imageRUNNER ADVANCE C9075 C7065 Series ...

Страница 49: ...47 b 23 Remove the 2 screws 1 1 stepped screw 2 and 1 hook 3 to detach the hopper unit Bk 4 ...