7

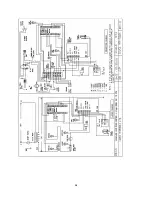

7. SAFETY DEVICES

7.1 WATER FLOW SWITCH (shipped loose)

A water flow switch is shipped loose and is to be installed in the outlet piping on all heating

boilers and hot water supply boilers. The flow switch is wired in series with the 24VAC safety

control circuit. A diagnostic light will be indicated on the control display on a low flow condition.

7.2 LOW WATER CUTOFF (If Equipped)

If this boiler is installed above radiation level, a low water cut-off device must be installed at the

time of boiler installation. Some local codes require the installation of a low water cut-off on all

systems. Electronic low water cut-offs are available as a factory supplied option on all models.

Low water cut-offs should be tested every six months. The normally open switch contact of the

low water cutoff is to be wired in series with the flow switch. A diagnostic light will be indicated

on the control display on a low flow condition. Caution: remove jumper when connecting to 24

VAC circuit.

7.3

RELIEF VALVE (shipped loose)

This appliance is supplied with a relief valve sized in accordance with ASME Boiler and

Pressure Vessel Code, Section IV (“Heating Boilers”). The relief valve is to be installed in the

vertical position and mounted in the hot water outlet. No valve is to be placed between the relief

valve, and the appliance. To prevent water damage, the discharge from the relief valve shall be

piped to a suitable floor drain for disposal when relief occurs. No reducing couplings or other

restrictions shall be installed in the discharge line. The discharge line shall allow complete

drainage of the valve and line. Relief valves should be manually operated at least once a year.

8. FREEZE PROTECTION

Boiler installations are not recommended in areas where the danger of freezing exists unless

precautions are taken. Maintaining a mixture of 50% water and 50% propylene glycol is the

preferred methods of freeze protection in hydronic systems. This mixture will protect the boiler

to approximately -35 °F (-37 °C). To maintain the same temperature rise across the boiler

increase the G.P.M. flow by 15% and the head loss by 20%.

A snow screen should be installed to prevent snow and ice accumulation around the boiler.

Regular inspections should be made to ensure that air intake and vent are free of snow and ice.

Содержание BLUE-FLAME Series

Страница 21: ...19...

Страница 22: ...20...

Страница 23: ...21 21 EXPLODED VIEW...

Страница 24: ...22 22 BLUE FLAME REPLACEMENT PARTS LIST...