INSTRUCTION, USE AND

MAINTENANCE MANUAL

Page 17 of 36

GB

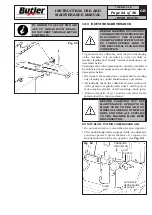

12.4 Wheel clamping on the mandrel

To block the wheel from inside:

1. Grease tyre edges with the grease contained in the

appropriate cup (see operating figure

Fig. 15

).

2. Release the hexagon shaft (

Fig. 15 ref. 2

) through

the relevant push-button on handle (

Fig. 15 ref. 1

)

and take it up, fully home. Control horizontal arm

(

Fig. 15 ref. 3

) tilting through the pedal.

3. The wheel can be secured to the mandrel by placing

jaws either inside or outside the rim (see Chapter

15 “Technical specifications” for required rim size).

WHEN SECURING THE WHEEL DO

NOT KEEP HANDS UNDER THE

TYRE.

Make sure that the wheel is placed at the centre of

the self-centring table (

Fig. 15 ref. 6

). Make sure

the wheel is clamped by jaws (

Fig. 15 ref. 7

) sym-

metrically.

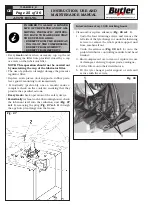

B) WHEEL SECURING OUTSIDE THE RIM

(for

allowed rim size, see Chapter 15 Technical speci-

fications)

In order to carry out the clamping of the wheel from

the outside:

1. pressing pedal (

Fig. 15 ref. 9

) in intermediate posi-

tion, place the 4 fixing jaws (

Fig. 15 ref. 7

) at the

same level of the tyre diameter.

2. Place the wheel on the mandrel, press the rim down-

ward and completely lower pedal (

Fig. 15 ref. 9

)

to secure the wheel.

B) WHEEL SECURING (INSIDE THE RIM)

(for al-

lowed rim size, see Chapter 15. “Technical speci-

fications”)

To block the wheel from inside:

1. close preventively fixing jaws (

Fig. 15 ref. 7

), by

means of pedal (

Fig. 15 ref. 9

). Place the wheel on

the mandrel. Push down the rim while completing

lowering the pedal and releasing it. The jaws release,

thus securing the rim.

Fig. 15

7300-M023-0_B

HP441S.XX - HP441S.XXFI

HP441SQ.XX - HP441SQ.XXFI