INSTRUCTION, USE AND

MAINTENANCE MANUAL

Page 24 of 36

GB

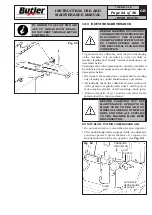

IN ORDER TO ALLOW THE AIR

JET TO BREAK BOTH BEADS,

DO NOT KEEP THE BEAD LIFTED

FORCING IT.

Fig. 25

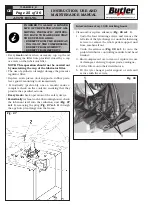

13.0 ROUTINE MAINTENANCE

BEFORE CARRYING OUT ANY ROU-

TINE MAINTENANCE PROCEDURE,

DISCONNECT THE MACHINE

FROM ITS POWER SUPPLY SOURC-

ES, TAKING SPECIAL CARE OF

THE ELECTRICAL PLUG/SOCKET

CONNECTION.

To guarantee the efficiency and correct functioning

of the machine, it is essential to carry out daily or

weekly cleaning and weekly routine maintenance, as

described below.

Cleaning and routine maintenance must be conducted

by authorized personnel and according to the instruc-

tions given below.

• Disconnect the mains power supply before starting

any cleaning or routine maintenance operations.

• Periodically check the calibration of the lubricator

of the pressure regulator/oiler unit: 1 oil drop every

four complete strokes of self-centering chuck jaws.

• Remove deposits of tyre powder and other waste

materials with a vacuum cleaner.

BEFORE CARRYING OUT ANY

MAINTENANCE OPERATIONS,

MAKE SURE THERE ARE NO

WHEELS CLAMPED ON THE MAN-

DREL AND THAT ALL SUPPLIES

TO THE MACHINE HAVE BEEN

DISCONNECTED.

DO NOT BLOW IT WITH COMPRESSED AIR.

• Do not use solvents to clean the pressure regulator.

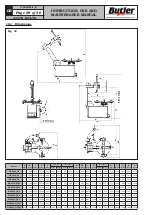

• The conditioning unit is equipped with an automatic

vacuum-operated drain therefore it requires no

manual intervention by the operator (see

Fig. 26

).

PRESSURE

REGULATOR

AIR

SUPPLY

AUTOMATIC

DEPRESSURE

RELEASE

OILER

Fig. 26

7300-M023-0_B

HP441S.XX - HP441S.XXFI

HP441SQ.XX - HP441SQ.XXFI