11

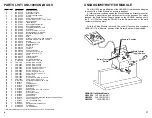

EXPLODED VIEW / PARTS LIST /

BUG-1856 UNI-BUG WELDING GROUP

ITEM

QTY

PART NO.

DESCRIPTION

1

2

BUG-1853

Machined Rack 7-1/2"

2

1

BUG-1881

Cable Anchor w/Swivel Clamp

3

1

BUG-2708

Clamp

4

1

BUG-5451

3.5" Rackholder

5

1

BUG-5462

Right Angle Clamp

6

1

CON-1020

Clamp

7

2

FAS-0957

Fit Hd Soc Scr 1/4-20 x 3/4

8

1

UNI-1036

Rackrider w/Post

2

5

3

4

7

1

1

8

6

14

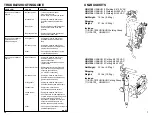

The UNI-BUG II can be adapted for dual welding applications as shown

below. A double racker mounting angle is bolted directly onto the left side of

the machine using two 1/4-20 socket head cap screws. Two 3.5" rackholders

are then mounted to the angle, each engaged with a 7-1/2" rack positioned

horizontally in opposite directions. At the end of each horizontal rack, a right

angle clamp block is attached allowing for an additional rackholder and

7-1/2" rack to be mounted vertically. At the end of each vertical rack, a swivel

clamp assembly and torch clamp are added. A cable anchor with swivel

clamp is mounted to the front right side of the UNI-BUG II to complete the

set up.

UNI-BUG II FOR DUAL WELDING

A UNI-BUG II converted for dual welding using a UNI-1350 UNI-BUG Dual

Welding Group.

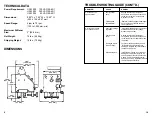

RACK MOUNTING

The handle mounting bracket has been redesigned so that it can be

mounted on either the left or right side of the machine. This allows the

rackholder and rack also to be mounted on either side. The welding gun can

then be positioned behind the drive desired, to reduce heating of the rollers.

UNI-1019 STEEL DRIVE ROLL

Optional hardened steel drive rolls are available for use when running on

a heated workpiece, which could melt the sleeves on the standard drive

rolls.

Order (2) UNI-1019 Steel Drive Rolls.