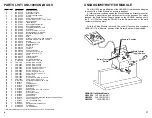

4

The UNI-BUG II is a small, lightweight, versatile machine originally de-

signed for the shipbuilding industry to weld or cut coamings, flanges, stiffen-

ers and similar joints. Previously this work could not be automated because

there was not enough room to mount a machine track system or the available

machines were too large to follow some of the workpiece curves or get into

tight work areas.

The UNI-BUG II is small enough to carry a cutting torch or welding gun

into tight work areas or around very tight curves without the use of a track.

The built-in carrying handle allows for easy mounting and removal at any

point along the workpiece. The UNI-BUG II can weld or cut both straight line

and on an inner radius as small as 6"(152 mm). It will travel at speeds of

4-75 ipm (102-1905 mm/min) with a 50 lb. (22.7 kg) horizontal pulling

capacity.

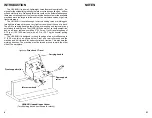

The UNI-BUG II is designed to run on the edge of a bar or stiffener up to

2" (50.8 mm) thick as shown below. Front and rear rollers support the

machine and tilt it forward for better control and traction. This also sets the

working direction. The machine must be turned around to weld the other

side of the workpiece.

INTRODUCTION

Direction of Travel

UNI-BUG II straddling an I-beam

(Torch holding devices not shown for clarity)

Idler screw knob

Rear support

roller

Front support roller

Carrying handle

21

NOTES: