2

Product description

Logano G615 - Subject to technical modifications

8

2.2

Operating conditions

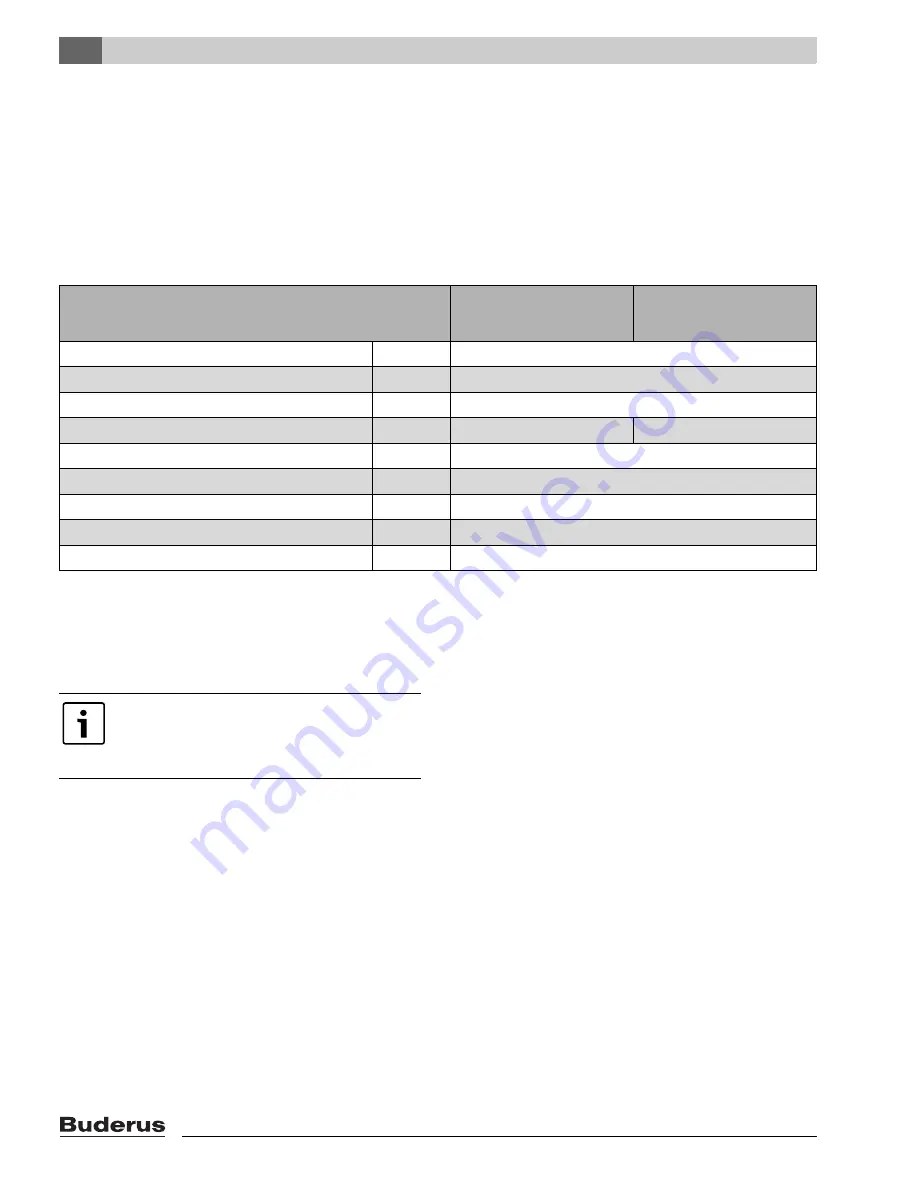

Thermostream technology is a unique feature of Buderus

cast iron boilers. Return water is preheated and mixed

within the boiler before it comes in contact with the

heating surface of the combustion chamber. The

Thermostream technology ensures there is an even

temperature distribution in the boiler and avoids

condensate forming within the combustion chamber. This

unique feature reduces thermal stress, the main cause of

failure of traditional cast iron boilers. The advantage of this

technology is the maintenance of the minimum operating

temperature of the boiler (

Æ

Tab. 3); this makes the

installation of a shunt pump unnecessary. This way, the

costs for the pump itself and its power consumption, as

well as possible failure costs are saved. The minimum

boiler operating temperature as shown in the table below

must be reached within 10 minutes and then be

maintained while the burner is running.

This operating condition can be easily achieved by the

controls monitoring the boiler temperature and reducing

the flow rate through the boiler until the required

temperature is reached. This is then maintained by

continuing to control flow based on the boiler water

temperature. The controls can reduce the flow rate by

closing the valves on the mixed heating circuits,

modulating the boiler primary pumps, closing the

motorized butterfly valves or by having a motorized valve

in the boiler return on a single boiler installation. The

Buderus 4000 series controls can manage this process

or it can be completed by the BMS.

If it is not possible for the control panel to regulate the

flow sufficiently to meet this operating condition, then a

shunt pump circuit must be fitted to avoid the type of

thermal stress that all boilers would experience in these

conditions. This shunt pump circuit can be controlled

either with a Buderus 4000 control or with a third-party

controller. Failure to ensure that the operating condition is

maintained may lead to thermal stress in the boiler and

eventual failure of the sections which would be outside

the scope of the warranty.

Control of all heating

zones with Buderus 4000

External controls (BMS) or

with Buderus 4212 with

ZM 427 or Aquastat control

Minimum flow rate

none

Minimum return temperature

°F ( °C)

none

Minimum operating temperature oil boiler

1)

1) This temperature has to be reached within ten minutes of the burner starting and has to be maintained whilst the burner is firing.

°F ( °C)

122 (50)

Minimum operating temperature gas boiler

1)

°F ( °C)

122 (50)

2)

2) 65 with partial load < 60 % °C

140 (60)

2)

Maximum supply temperature

°F ( °C)

212

3)

/248

4)

(100

3)

/120

4)

)

3) The maximum supply temperature is 212 °F (100 °C), if the boiler is operated as hot water boiler.

4) The maximum supply temperature is 248 °F (120 °C), if the boiler is operated as a hot water generator.

Maximum operating pressure

PSI (bar)

87 (6)

For operation with two-stageoil and gas bumers

–

Set the partial load stage to 60 %

Time constant of the temperature controller

sec

40

Time constant of the monitor/limiter

sec

40

Tab. 3

A heating zone with a mixing valve improves

controllability and is specifically

recommended for systems with differing

water temperature zones.