—22—

Table 8 — Modular Platform D Unit Configuration Values

Only the current value being displayed is transmitted. Once

the Fan button is pressed, the room controller will switch to

displaying the configuration item number. To move to the

next setting, press the Mode button again and the “20” will

be displayed. Press the Up button and the display will

change to “21.” The Mode button will toggle the display

between the software configuration item number (i.e., “20,”

“21,” etc.) and the configuration value. The Up and Down

buttons will change either the item number or the value,

whichever is displayed at the time.

This mode will exit automatically after 30 seconds of

inactivity.

NOTE

: If units are grouped to one room controller, all units

will have the same configuration value.

VI. SERVICE TEST MODE

Prior to start-up, conduct the Service Test mode to ensure

the unit is ready for start-up.

There is a hidden Service Test mode that is initiated through

a combination of button presses when the remote is off. The

following buttons need to be pressed, in sequence, within

6 seconds:

1. Down arrow

2. Fan button

3. Up arrow

4. Fan button

5. Mode button

Once in Service Test mode, the Service Test mode message

will be sent, and

Sr

will be displayed in the temperature

icons until the Down button is pressed. During Service Test

mode all the icons are off, and the only button that is active

is the Down button. To cancel Service Test mode, press the

Down button to send a message of Off mode to the unit. Ser-

vice Test mode automatically times out after 30 minutes and

the remote will operate normally.

When test mode is selected, the unit will operate as

described below:

• The Unit Status (Green) and Timer (Yellow) LEDs blink

every 2 seconds.

• The indoor fan will operate according to user-selected

speed. If user-selected speed is Auto, the fan will run in

High speed.

• If the unit is configured as an A/C Only unit, it will oper-

ate in cool mode with demand.

• If the unit is configured as a Heat Pump unit, the louver

will operate according to user-selected position. If user

selected louver is Auto, louver operates according to auto

heat or cool louver based on operating mode.

• The unit will run in cool mode for 3 minutes, then it will

run in heat mode for 2 minutes, or until the indoor coil is

greater than 104 F. The unit will run in cool mode until

test mode is exited.

Any of the following will cancel the Service Test mode:

• When the unit is turned off by the controller.

• If the power is cycled during the Test Mode, the unit will

return to its normal operating mode.

• After 30 minutes of receiving the last valid test request

message.

• Fail Mode.

START-UP

The following checks should be made before system start-up.

Refer to outdoor unit Installation, Start-Up, and Service

manual for system start-up instructions and refrigerant

charging methods. Be sure to use the refrigerant charge

shown in Table 3.

1. Check condensate drainage system.

a. Remove grille and frame from the unit.

b. On the opposite side of the drain connection,

insert a water bottle up into the fan coil unit and

fill drain pan. Refer to Fig. 34. Water must flow

regularly with condensate pump energized. If

water does not, check the pipe slope or see if

there are any pipe restrictions.

NOTE: The unit is equipped with a safety float

switch to deenergize the compressor if the drain

water level gets too high.

2. Make sure that all wiring connections are correct and

that they are tight.

3. Make sure that all barriers, covers, and panels are in

place.

ITEM

VALUE

COMMENT

20

1: Heat Pump

0: AC only (indoor unit with

or without electric heaters)

Unit Configuration

defaults to heat pump

21

1-199 in increments of 1

CCN Address of the unit.

Defaults to 1.

To display the hundreds,

push .

22

0-199 in increments of 1

Zone number -

Communications zone

the system is located in

Defaults to 0

To display the hundreds,

push

.

24

0: Start in Off mode

1: Start in last active mode

Auto Restart

Defaults to “On”

Room Controller

ON

up

down

Keep it pressed

for 5 seconds

To change

the value

Automatic

(AUTO)

Or

Continuous

movement

(swing)

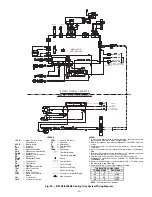

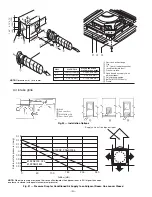

Fig. 33 — Selecting the Louver Mode