—10—

IV. STEP 4 — COMPLETE REFRIGERANT PIPING

CONNECTIONS

IMPORTANT:

During unit installation make the refrigerant

connections first and then the electrical connections. If the

unit is uninstalled, disconnect the electrical cables first and

then the refrigerant connections. Refer to the outdoor unit

installation instructions for tube sizing and limitations.

Use field-supplied refrigerant grade piping designed for use

with R-410A refrigerant.

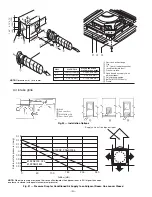

A. Flaring the Ends of Pipes

Remove the protective caps from the copper pipe ends. Hold-

ing the tube downward, cut the extreme end off, removing

any copper shavings with a deburring blade. Remove the

flare nuts from the “FLARE” connection body of the indoor

unit and insert them into the pipes. Make the flare to the

pipe end with the proper flaring tool. The flare end must not

have any burrs or imperfections. The length of the flared

walls must be uniform. See Fig. 18 and 19.

Lubricate the end of pipe and the thread of the flare connec-

tion with anti-freeze oil. Tighten by hand and then use two

wrenches to tighten all connections fully, applying the tight-

ening torque shown in Table 5. Refer to Fig. 20.

Table 5 — Tightening Torque

B. Piping Connection to the Unit

Use two wrenches to tighten all connections.

Once all connections have been completed, check for leaks

using soapy water. If no leaks were found, wrap connections

with anti-condensate insulation and tighten with tape, with-

out exerting excessive pressure on the insulation. Repair and

cover any possible cracks in the insulation.

If either refrigerant tubing or indoor coil is exposed to the

atmosphere, the system must be evacuated following good

refrigeration practices.

TUBE DIAMETER

(in.)

TORQUE

(ft-lb)

3

/

8

in.

31

5

/

8

in.

48

3

/

4

in.

74

CAUTION:

Insufficient tightening torque could

cause a refrigerant leak from the connection. Excessive

tightening torque will damage the pipe flare.

CAUTION:

DO NOT BURY MORE THAN 36 IN.

OF REFRIGERANT PIPE IN THE GROUND. If any

section of pipe is buried, there must be a 6-in. vertical

rise to the valve connections on the outdoor unit. If

more than the recommended length is buried, refriger-

ant may migrate to cooler, buried section during

extended periods of system shutdown. This causes

refrigerant slugging and could possibly damage the

compressor at start-up.

L

L

Adjustable wrench or torque wrench

Outdoor end

Indoor end

3

1

2

Fig. 18 — Removing Burrs

Fig. 19 — Flared Walls are Equal

Fig. 20 — Tightening Connections