—11—

V. STEP 5 — MAKE ELECTRICAL CONNECTIONS

See Tables 6A and 6B for electrical information.

A. Units With Electric Heater

The unit is equipped with two thermostats: one with auto-

matic reset and one with manual (electric) reset that can be

reactivated by switching the power supply off and then

back on.

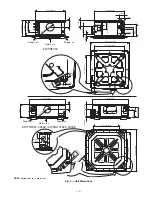

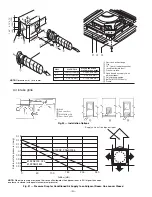

B. Power Wiring (Fig. 21-26)

The unit is factory wired for voltage shown on nameplate.

Provide adequate, fused disconnect switch within sight from

unit, readily accessible, but out of reach of children. Provi-

sion for locking the switch open (off) is advisable to prevent

power from being turned on while unit is being serviced. Dis-

connect switch, fuses, and field wiring must comply with the

NEC and local code requirements. Use copper wire only

between the disconnect switch and unit. Use minimum 60 C

wire for the field power connection.

Remove the external box cover. Route the low voltage wires

from the outdoor unit to the indoor unit:

1. Place wiring through

7

/

8

in. knockouts on the left or

right hand side of external control box (low voltage

side).

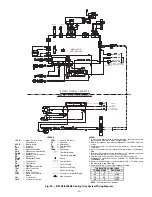

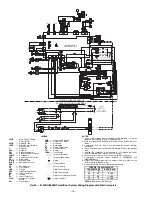

2. Connect the R and Y wires to the 2 pin terminal block

for cooling only units (619FNF) and heat pump units

(619FNQ) that are matched to 538ENF outdoor units.

3. Connect the R, Y, O, G, DT, A, and B wires to the

(PGB-1) 1 terminal for 619FNQ indoor units matched

with 538QNF outdoor units.

Route the line power leads from the indoor disconnect to the

fan coil unit.

1. Place wiring through

7

/

8

in. or 1

1

/

8

in. knockouts on

the left and on the right hand side of external control

box (high voltage side).

2. Connect L1 to the black wire and L2 to the red wire

using wire nuts and fix the ground wire between the

2 washers.

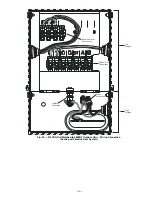

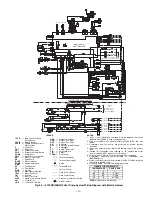

See Fig. 27 for a view of the internal control panel. The inter-

nal control panel can be accessed by opening the grille and

removing the metal cover attached by four screws.

NOTE:

The internal control panel does not need to be

accessed during the installation process unless there is a

need for service.

Table 6A — 619FNF Fan Coil Electrical Data

LEGEND

*Permissible limits of the voltage range at which unit will operate

satisfactorily.

NOTE:

In compliance with NEC requirements for multimotor and combina-

tion load equipment (refer to NEC Articles 430 and 440), the overcurrent pro-

tective device for the unit shall be fuse or equipped with a breaker.

Table 6B — 619FNQ Fan Coil Electrical Data

LEGEND

*Permissible limits of the voltage range at which unit will operate

satisfactorily.

NOTE:

In compliance with NEC requirements for multimotor and combina-

tion load equipment (refer to NEC Articles 430 and 440), the overcurrent pro-

tective device for the unit shall be fuse or equipped with a breaker.

WARNING:

Unit cabinet must have an uninter-

rupted, unbroken electrical ground to minimize the

possibility of personal injury if an electrical fault

should occur. This ground may consist of electrical

wire connected to unit ground lug in control compart-

ment, or conduit approved for electrical ground when

installed in accordance with NEC, and local electrical

codes. Failure to follow this warning could result in the

installer being liable for the personal injury of others.

CAUTION:

Unit failure as a result of operation on

improper line voltage or excessive phase imbalance

constitutes abuse and may cause damage to electrical

components. Such operation would invalidate any

applicable Bryant warranty.

WARNING:

Electrical shock can cause personal

injury and death. Shut off all power to this equipment

during installation. There may be more than one dis-

connect switch. Tag all disconnect locations to alert

others not to restore power until work is completed.

SYSTEM

SIZE

V-PH-Hz

VOLTAGE

RANGE*

FAN

CONDENSATE

PUMP FLA

LOUVER

MOTOR FLA

POWER

MIN WIRE

SIZE

AWG

Min

Max

FLA

Motor Power

(Watts)

MCA

MOCP

018

208/230-1-60

187

253

0.55

120

0.06

0.01

0.8

15

14

024

208/230-1-60

187

253

0.50

110

0.06

0.01

0.7

15

14

030

208/230-1-60

187

253

0.95

210

0.06

0.01

1.3

15

14

036

208/230-1-60

187

253

0.95

210

0.06

0.01

1.3

15

14

AWG

—

American Wire Gage

FLA

—

Full Load Amps

MCA

—

Minimum Circuit Amps per NEC Section 430-24

MOCP —

Maximum Overcurrent Protection

NEC

—

National Electrical Code

SYSTEM

SIZE

V-PH-Hz

VOLTAGE

RANGE*

FAN

CONDENSATE

PUMP FLA

LOUVER

MOTOR FLA

ELECTRIC

HEATERS

POWER

MIN

WIRE

SIZE

AWG

Min

Max

FLA

Motor Power

(Watts)

kW

FLA

MCA

MOCP

018

208/230-1-60

187

253

0.50

110.0

0.06

0.01

3

12.5

16.3

20

12

024

208/230-1-60

187

253

0.50

110.0

0.06

0.01

3

12.5

16.3

20

12

030

208/230-1-60

187

253

0.95

210.0

0.06

0.01

3

12.5

16.9

20

12

036

208/230-1-60

187

253

0.95

210.0

0.06

0.01

3

12.5

16.9

20

12

AWG

—

American Wire Gage

FLA

—

Full Load Amps

MCA

—

Minimum Circuit Amps per NEC Section 430-24

MOCP —

Maximum Overcurrent Protection

NEC

—

National Electrical Code