—21—

III. ROOM CONTROLLER CONFIGURATION SETUP

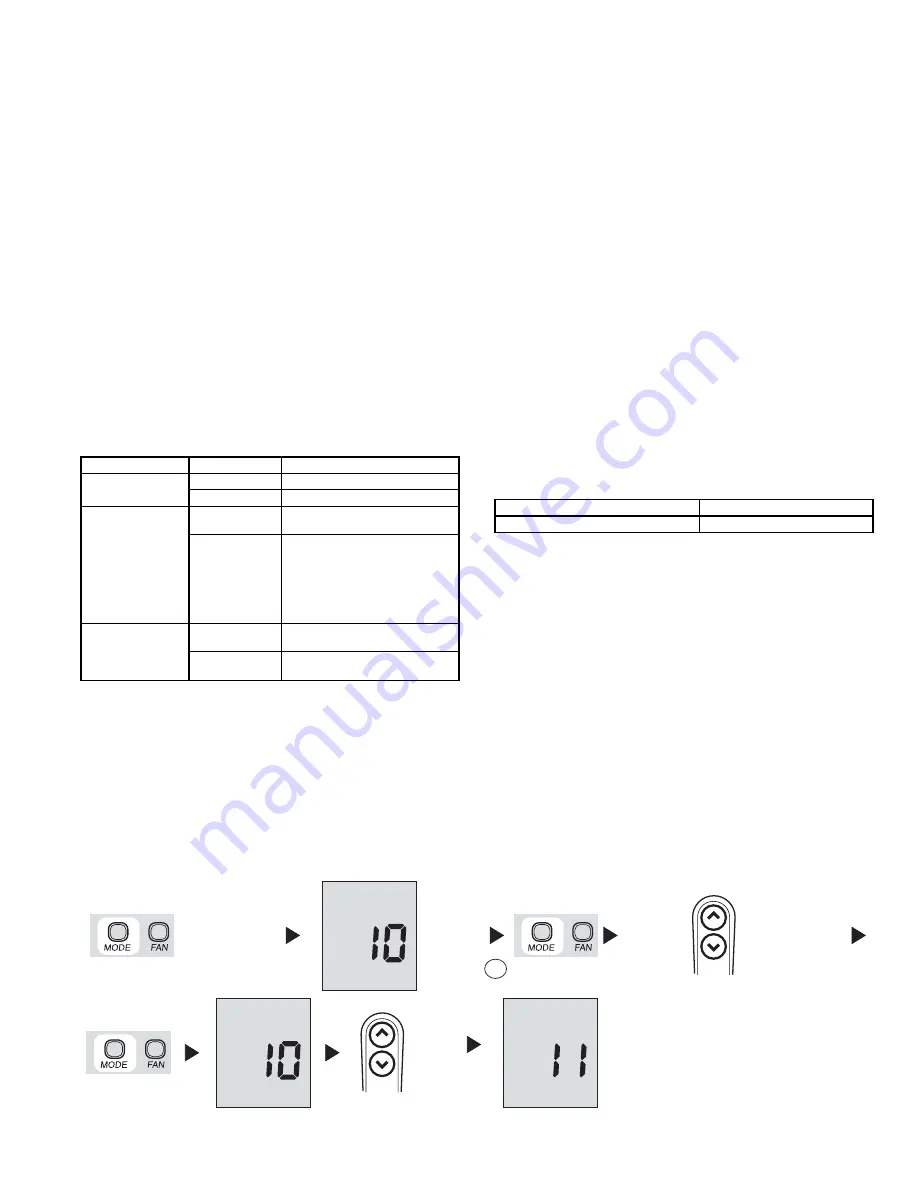

To configure the room controller, press the Mode button for

5 seconds. After 5 seconds, “10” will appear. This indicates

that the user is setting the first software configuration item.

To display the value of configuration item 10, press the Mode

button again. The value of the Heat/Cool vs Cooling only

remote configuration will be displayed along with the “Set

Temp” icon to indicate that the number displayed is the con-

figuration data. Refer to Table 7 for configuration values. To

change the Heat/Cool vs Cooling only remote Configuration,

press the Up and Down buttons. To move to the next setting,

press the Mode button again and the “10” will be displayed.

Press the up button and the display will change to “11.”

Refer to Fig. 32. The Mode button will toggle the display

between the items and the configuration value. The Up and

Down buttons will change either the index or the value,

whichever is displayed at the time. Press the Fan button to

exit the Configuration Setup Mode. This mode will exit auto-

matically after 10 seconds of inactivity. Once a configuration

value is changed, the last value displayed will be the new

configuration value for the room controller.

NOTE

: The only way to abort a configuration change is to

change the value back to its original value.

Table 7 — Room Controller Configuration Values

* Factory default.

1. Configuration Item 10: Heat Pump vs Cooling Mode

H — The Room Controller will allow and display the

following modes:

•Off

•Fan

•Auto

•Cool

•Dry

•Heat

C — The Room Controller will allow and display the

following modes:

•Off

•Fan

•Cool

•Dry

2. Configuration Item 11: Room Thermistor Override

On — Room Thermistor Override is active. Units will

be controlled to the air temperature displayed via the

Room Controller.

Of (Off) — Room Thermistor Override is not active.

All units will be controlled to the room air ther-

mistors located on the units.

3. Configuration Item 12: Celsius vs Fahrenheit

C — Temperatures will be displayed in degrees

Celsius.

F — Temperatures will be displayed in degrees

Fahrenheit.

IV. LOUVER MODE SELECTION

To enter louver mode selection, ensure the room controller is

on and then press the Fan button for 5 seconds. After 5 sec-

onds, the selected louver setting will be displayed. Press the

up and down arrows to modify the louver setting between

swing and auto. Refer to Fig. 33. The two settings will be dis-

played as follows:

The fan icon will also be displayed in the louver mode. Press

Fan button to exit the Louver Mode selection. This mode will

exit automatically after 10 seconds of inactivity. The only

way to abort a louver change is to change the value back to

its original value.

NOTE:

If units are grouped to one room controller, all units

will have the same louver value. Louver Mode selection is

not available during OFF mode.

V. MAIN BOARD CONFIGURATION

To configure the main electronic board, push the Up and

Down arrows for 5 seconds while the room controller is off.

After 5 seconds, a “20” will appear. This indicates that the

user is setting the first software configuration item. To check

the value of configuration item “20,” press the Mode button.

The value for the Heat Pump/AC Only configuration will be

displayed. To change the value, use the Up and Down

buttons. Once the desired value is selected, press the Fan

button to send that configuration data to the unit. Refer to

Table 8.

ITEM

VALUE

DESCRIPTION

10

H*

Heat/Cool Remote

C

Cooling Only Remote

11

On

Room Thermistor Override

Active.

Of*

Control and display room air

temperature at the room con-

troller. Room Thermistor Over-

ride Inactive. Do not display

room air temperature at the

room controller and control to

unit room air thermistor(s).

12

C*

Temperatures displayed in

degrees Celsius.

F

Temperatures displayed in

degrees Fahrenheit.

S with Swing Louver Icon

Represents the swing louver

A with Auto Louver Icon

Represents the auto louver

Keep it pressed for

at least 5 seconds

Check the

value

Change the

value

up

down

Next

item

up

down

To check/change

the values of items

11 and 12 go back

to point

A

A

Fig. 32 — Room Controller Configuration Steps