Bronkhorst®

Instruction Manual EL-PRESS™

9.17.101I

28

3.6.2.2

Software (DDE applications)

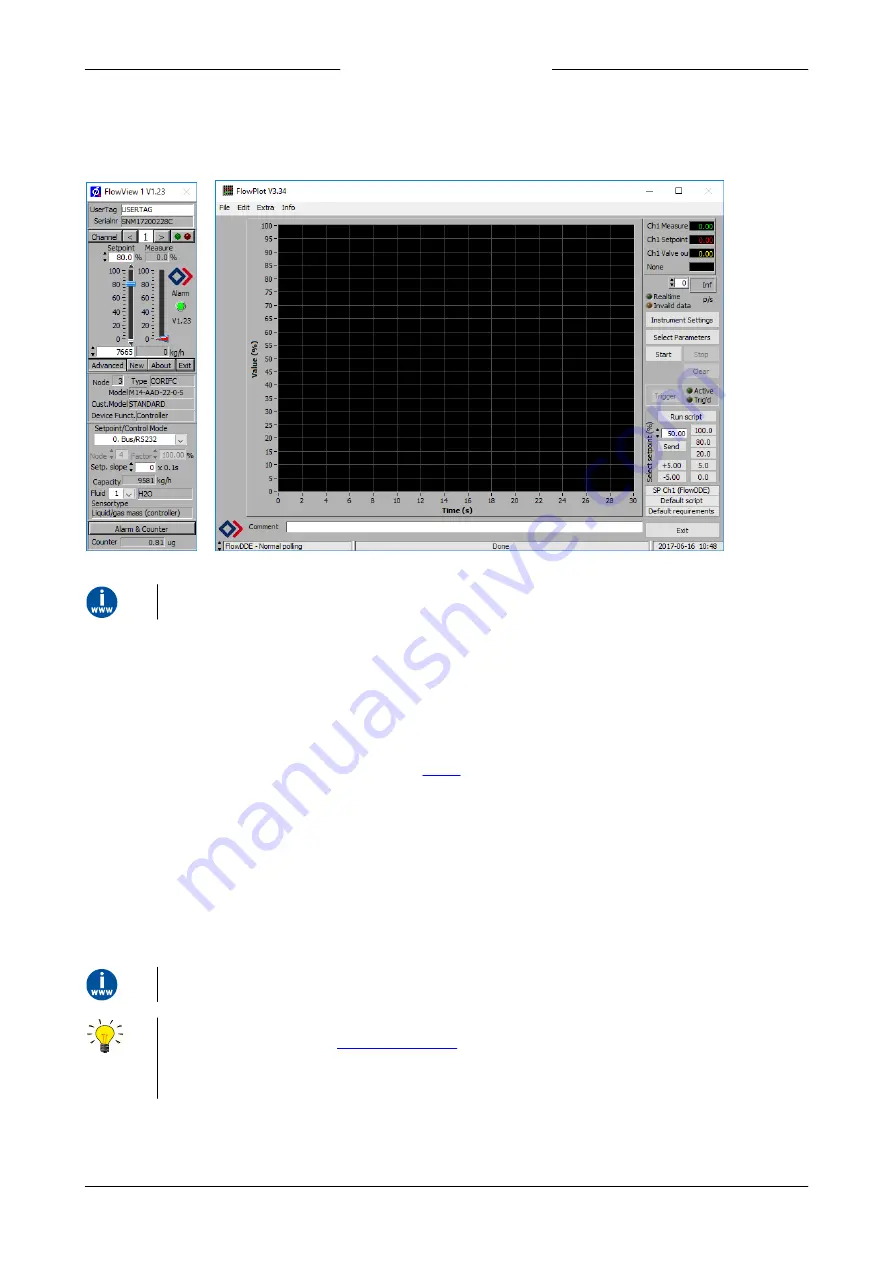

Examples of free Bronkhorst® DDE client applications: FlowPlot and FlowView. Other software programs (third party)

supporting DDE are for example MS-Office, LabVIEW, InTouch and Wizcon.

Bronkhorst® software applications 'FlowView' (left) and 'FlowPlot' (right)

FlowDDE and other Bronkhorst® applications are available on the support CD or can be downloaded from the product

pages on the Bronkhorst website:

3.6.3

Digital fieldbus operation (RS485)

The following optional fieldbus interfaces are available for

EL-PRESS™

instruments. For all mentioned fieldbus systems,

except FLOW-BUS, instruments act as slaves on the master/slave bus system. There is no mutual communication between

slaves, only between master and slave.

FLOW-BUS

Digital Bronkhorst® instruments can be monitored and operated via RS-232 using the free

FlowWare

software tools for

Windows. These tools provide a graphical interface to the

protocol (used by FLOW-BUS), for monitoring and

changing instrument parameters.

The FlowWare toolkit provides functionality for monitoring and operating digital instruments (FlowPlot, FlowView) and

selection of the active fluid and configuration of the fieldbus connection (if applicable). For instruments that support the

definition and use of multiple fluids FlowTune™ can be used to define and store fluids in the instrument and select the

active fluid.

Digital instrument parameters are made accessible by

FlowDDE

, a Dynamic Data Exchange server (DDE) that handles

communication between the instrument and (dedicated) client software in Windows (e.g. FlowPlot). FlowDDE can also be

used by other client applications, such as Microsoft Office or custom made software, built with third party development

software like LabVIEW or a SCADA platform.

The FlowWare tools and associated documentation can be downloaded from the product pages on the Bronkhorst website:

FlowWare can only be used if the 9-pin D-sub (power) connector is configured for RS232 communication. If necessary , use

the power-up functionality of the

to switch to configuration mode and enable RS232

communication.

After configuring the required parameters, remember to leave configuration mode and restore the original

communication settings (otherwise, configuration mode remains enabled after power down).