Bronkhorst®

Instruction Manual Controlled Evaporator and Mixer

9.17.126A

17

3.6

Purging

Purging the fluidic lines of the CEM system is sometimes necessary, to prevent clogging of the tubing and instrumentation

or (cross) contamination of process media. Purging the entire fluidic system is advised at the following occasions:

·

before changing fluid types

·

before and after using corrosive, reactive or explosive media

·

before and after a shutdown period of more than one week

·

every 3 months

Always use a dry, inert gas (like Nitrogen or Argon) to purge the fluidic system.

The purge times mentioned in the instructions below are rough indications; depending on the media properties (density,

viscosity, volatility, etc.), longer or shorter times might be recommendable.

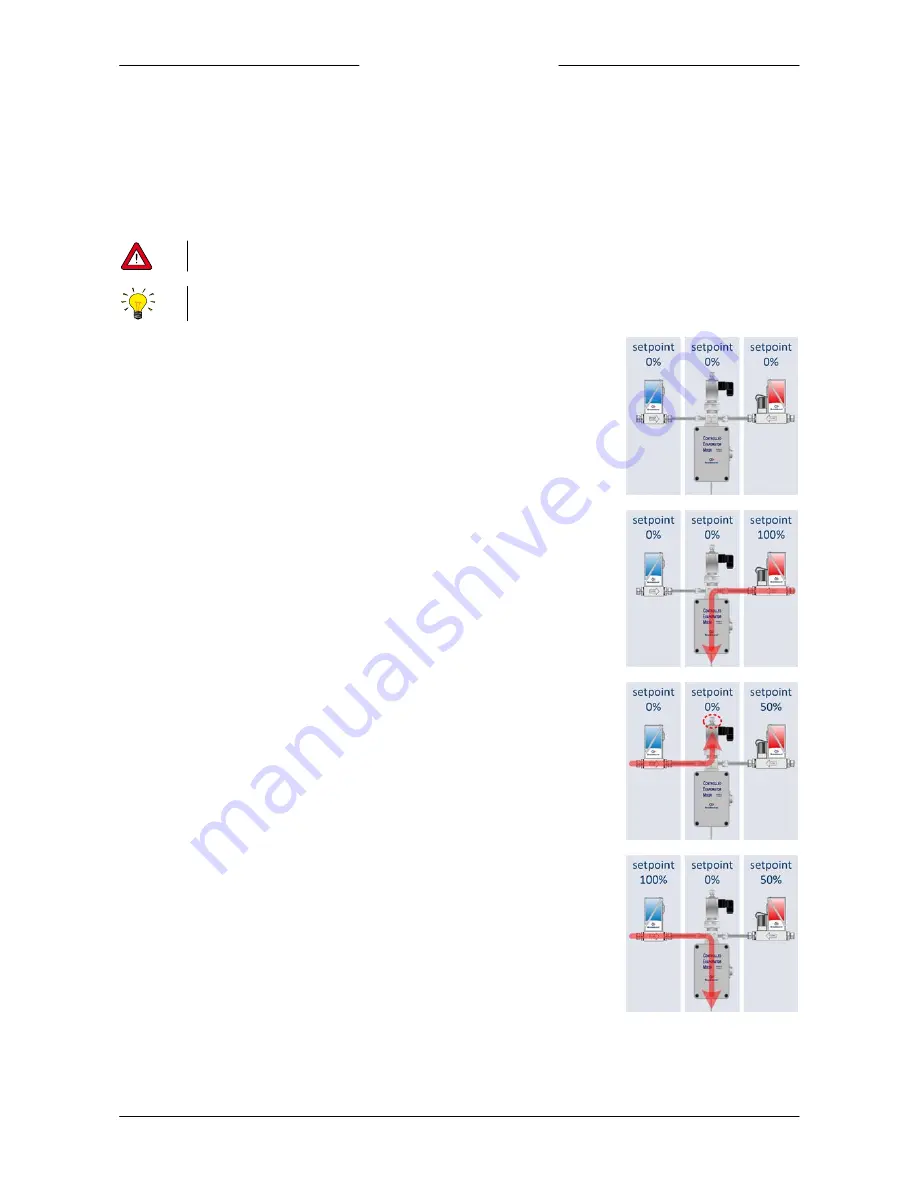

Step 1: Preparation

a. Set all setpoints to 0% (liquid flow, carrier gas flow, CEM

temperature)

b. Connect a purging gas supply facility to the inlets of

both

flow controllers

(liquid and gas)

c. Pressurise the purging gas supply line

Step 2: Gas tubing

a. Change the carrier gas flow setpoint to 100%

b. Purge for at least 30 minutes

Step 3: Mixing valve

a. Change the carrier gas flow setpoint to 50%

(this will help prevent liquid from flowing into the gas tubing

and flow controller)

b. Open the bleed connection on top of the mixing valve

c. Purge for 10 to15 minutes

d. Close the bleed connection

Step 4: Liquid tubing

a. Change the liquid flow setpoint to 100%

b. Purge for at least 30 minutes

Step 5: Finishing

a. Set the carrier gas flow setpoint to 0%

b. De-pressurise the purging gas supply line

c. Set the liquid flow setpoint to 0%