Installation

WF2613

Bradley

•

215-1451 Rev. F; ECN 13-00-001

3/5/2013 17

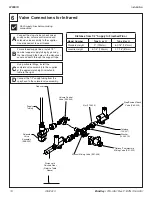

I.R. Module Assembly Components (S83-046)

Window

(269-832)

Sensor

S83-039

Model Cover Assembly

(S04-083)

Troubleshooting Adaptive IR

Problem

Cause

Solution

LED not

illuminated.

No power is

getting to the

sensor.

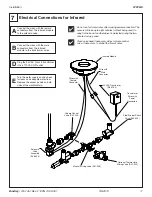

Check for power at the 110 VAC wall outlet and from the wires from the 24 VAC transformer. If there

is 110 VAC power at the wall outlet, but no power from the transformer, touching leads from the

transformer while plugged in or a power surge may have burned out the transformer. Add surge

protection at the outlet if a power surge is suspected and replace the transformer. If 24 VAC power is

being supplied from the transformer, check for loose wire connections and check connections against

the wiring diagram.

Fast blink

Sensor is

detecting

something in

it's view and

water should

be on (power

is being

sent to the

solenoid)

If the sensor is blinking fast, the water is turning on and there is nothing in the detection area,

disconnect the power for at least 30 seconds. This will allow the sensor to loose it’s memory and be

reset. Reconnect the power and wait 2 full minutes to allow the sensor to relearn the environment

before attempting to activate. The sensor may take up to 8 minutes to readjust if it activated during

those 2 minutes.

If the condition persists, make sure the LEDs at the ends of the sensor cables are pushed all the way

in to the backs of the lenses.

If the sensor is blinking fast and the water is not turning on, go through the troubleshooting guide for

the solenoid.

Slow blink

Sensor is

detecting

something in

it's view and

the water is off

(power is not

being sent to

the solenoid).

The sensor has detected a stationary object in its view for more than 30 seconds and shut off power

to the solenoid valve. Remove the object, if it is still in the bowl, and reset the sensor as explained

above.

Blinking SOS

(3 short, 3

long, 3 short)

The sensor

has detected

an overload

condition and

shut down

to protect it's

circuits.

Check connections against the wiring diagram. This condition usually means the solenoid valve is not

properly wired. After correcting any wiring error, it will be necessary to reset the sensor as explained

above.

If you need further assistance, please call your local Bradley representative. Please call us at 1-800-Bradley if you need the name

and telephone number of your local Bradley representative.

There is a LED diagnostic light built into the small black box housing the circuitry for the sensor. Below is a list of what the signals

from the LED mean. Use this list to troubleshoot the sensor.

Sensor Bracket

140-718